FMC™ Series

Polysulfide Mold Rubber

FMC™ rubber molds are very durable and will last for years in production casting of wax or gypsum. Ideal for those applications that require capturing intricate detail from a variety of model surfaces. Unlike polyurethanes, FMC™ is not sensitive to moisture or sulfur and can be poured directly over wet plaster or water/sulfur based clays. Common applications include molds for foundry and pattern work, sculpture (lost wax process) and casting architectural gypsum pieces.

HIGHLIGHTS

Foundry Molds

Foundry Molds

Because FMC™ Polysulfide rubber is not inhibited by sulfur, original sculptures often done in a sulfur bearing modelling clay referred by sculptors (Roma Plastalina), FMC™ is perfect for casting foundry wax (lost wax process) and last a long time in mold libraries.

Gram Scale Required

Gram Scale Required

Production Molds

Production Molds

FMC™ Castable Polysulfide Mold Rubbers have been used for years to make tire pattern molds. They continue to be used today by Goodyear, Bridgestone, Firestone and other major tire manufacturers around the world.

Gram Scale Required

Gram Scale Required

Industrial Grade

Industrial Grade

Technical and Buying Information

| Select a Product Below | Pot Life | Cure Time | Hardness |

|---|---|---|---|

| › FMC™ 200 | 50 mins | 16 hrs | 20 A |

| › FMC™ 201 | 50 mins | 16 hrs | 15 A |

| › FMC™ 205 | 90 mins | 16 hrs | 12 A |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Make a Polysulfide Rubber Mold of a Masterpiece

Learn about the mold making process for casting a da Vinci horse design.

What Have Other People Done With These Products?

DaVinci's Masterpiece Has Homecoming

After 500 Years - DaVinci's Masterpiece Comes Home...For the First Time.

Casting the World’s Largest Sculpture in Smooth-On FMC-200™

The Ushiku Daibutsu located in Ushiku, Ibaraki Prefecture, Japan, is the world's tallest freestanding bronze statue.

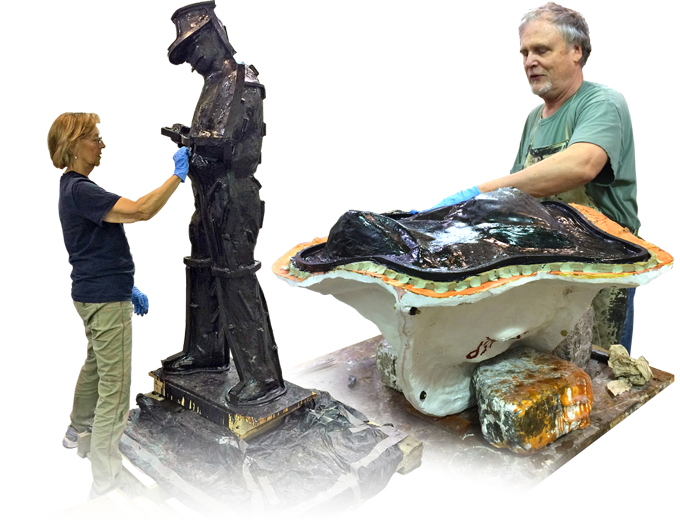

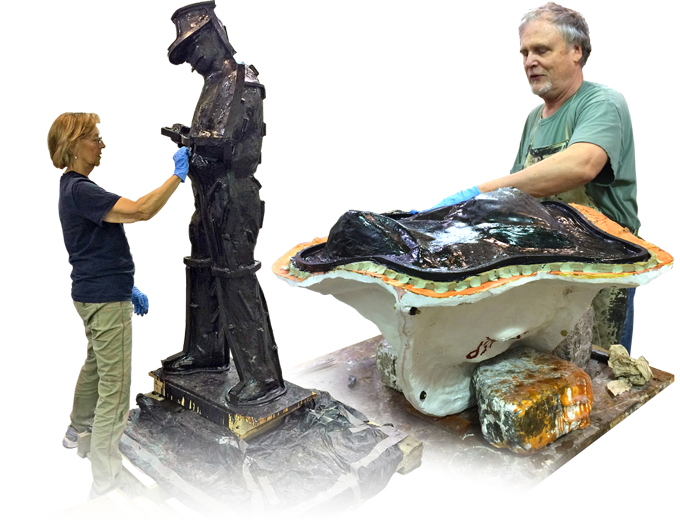

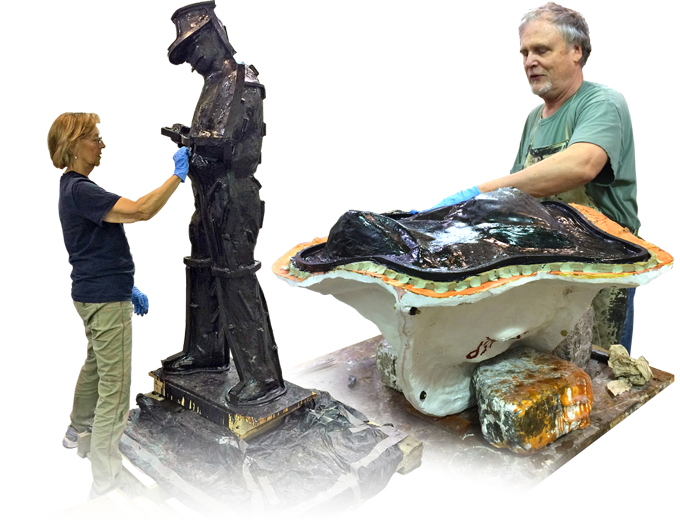

Johnson Atelier Uses Polysulfide Rubber To Bring Sculpture to Life

Since its inception 30 years ago, the Johnson Atelier has used Smooth-On's full line of Polysulfide rubbers.