Urethane Rubber Accessories

Take Your Urethane Rubber Further

Additives compatible with Smooth-On Urethane Rubber Compounds for altering and enhancing their characteristics and performance. Choose from a variety of colorants and fillers, cure accelerator, softening agent, UV resistance enhancer, adhesive and more.

HIGHLIGHTS

Color Pigments and Tints

A Little Goes a Long Way

Color Pigments and Tints

A Little Goes a Long Way

- SO-Strong™ colorants are highly concentrated, offer excellent dispersion and consistent color.

- UVO™ Colorants are phthalate-free color pigments that resist ultra-violet light.

- Ignite™ pigments are fluorescent colorants. Castings appear brighter and appear to glow under ultraviolet light.

Kick-iT!™

Urethane Rubber Cure Accelerator

Kick-iT!™

Urethane Rubber Cure Accelerator

Additive designed to “accelerate” the cure time of VytaFlex™, ReoFlex™ and PMC™ rubber products without significantly affecting the ultimate physical properties.

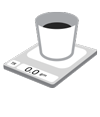

Gram Scale Required

Gram Scale Required

SO-FLEX™ II

Flexibilizer for Urethane Rubber

SO-FLEX™ II

Flexibilizer for Urethane Rubber

Softening agent that will lower the cured durometer of a variety of Smooth-On flexible polyurethane products. Can also be added to Vytaflex™ 10 to create a urethane ‘gel’ type material.

Recommend Measure by Weight

Recommend Measure by Weight

Choose the Percentage

Choose the Percentage

Sun Devil™

UV Resistant Additive

Sun Devil™

UV Resistant Additive

A one component liquid additive that will slow color change and physical degradation due to UV exposure for many Smooth-On liquid urethane products.

Gram Scale Required

Gram Scale Required

UV Resistant

UV Resistant

XTEND-IT™

Dry Gas Blanket

XTEND-IT™

Dry Gas Blanket

Designed to extend the shelf life of unused moisture sensitive polyurethane products. Applying the XTEND-IT™ to the unused portion of a liquid polyurethane system will minimize residual moisture in the container and significantly extend the shelf life of what remains.

Great Value

Great Value

URE-BOND™ II

Urethane Adhesive

URE-BOND™ II

Urethane Adhesive

Premium performance urethane adhesive compound that offers a strong flexible bond between many different surfaces. Ideal for adhering polyurethane rubber and other polymer products to many types of substrates

Scale Not Necessary

Scale Not Necessary

One to One by Volume

One to One by Volume

Cryptolyte™

UV Glow Additive

Cryptolyte™

UV Glow Additive

Causes cured Smooth-On silicone rubbers, urethane rubbers, plastics or foams to glow a bright blue under a focused ultra violet light source (blacklight). At low percentages it will not affect clarity or color of material and the glow effect will not be evident until the casting is illuminated by a UV light source.

Scale Not Necessary

Scale Not Necessary

URE-FIL™ 9, URE-FIL™ 11

Thickening Agents

URE-FIL™ 9, URE-FIL™ 11

Thickening Agents

Primarily used with liquid urethane rubbers for brush-on moldmaking applications. URE‑FIL™ 9 is a fumed-silica based thickening agent added in small amounts to the mixed rubber until the desired viscosity is achieved. URE‑FIL™ 11 is a fiber-based filler.

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › SO-Strong™ | Colorants for Urethane Rubber, Resin and Foam |

| › Ignite™ | Fluorescent Colorants For Liquid Rubber, Plastic and Foam |

| › UVO™ | UV Resistant Colorants for Epoxy and Urethane. |

| › Kick-iT!™ | Cure Accelerator For Urethane Rubber |

| › SO-FLEX™ II | Softening Agent For Urethane Rubber |

| › Sun Devil™ | UV Resistant Additive |

| › XTEND-IT™ | Dry Gas Blanket |

| › URE-BOND™ II | Flexible Urethane Adhesive |

| › Cryptolyte™ | UV Glow Additive for Urethanes and Silicones |

| › URE-FIL™ 9 | Fumed-Silica Based Thickening Agent |

| › URE-FIL™ 11 | Fiber Filler for Urethane and Silicone |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Make a Foam Prop Sword Using a Silicone 2 Part Mold

How a 3D printed master is used to pour a silicone mold for a prop sword