Jason and Jenny Wilhelm, owners of Dope on a Rope Soaps (Bailey, CO) have been using OOMOO 25 silicone rubber for years to make their all-natural soap products, including their popular namesake Dope on a Rope Soap. Building upon their success, they expanded their line to include the new Trout on a Rope Soap. They proudly share their mold making and casting process with us during the creation of this new product.

OOMOO silicone is a good material choice because their original trout model has no undercuts and a flat back (2-dimensional). Since the model is relatively shallow that means the mold does not require a great deal of elasticity or tear strength when demolding. Try Mold Star Series silicone if you need better tear strength with the same ease of use.

To date, they have pulled over 20,000 pieces of soap from OOMOO molds. With so many castings pulled from their molds, the mold material cost was virtually zero.

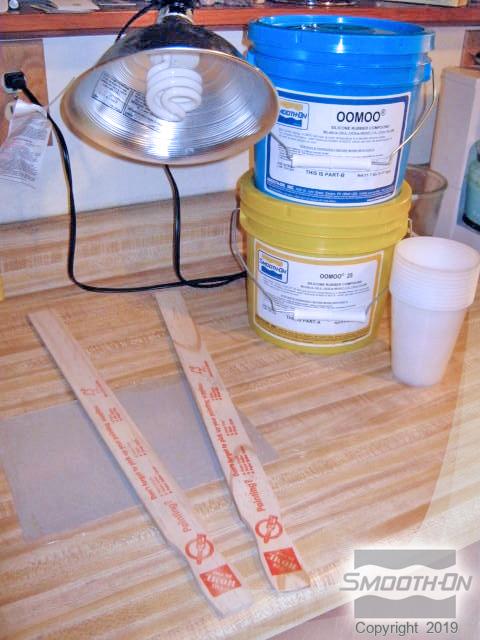

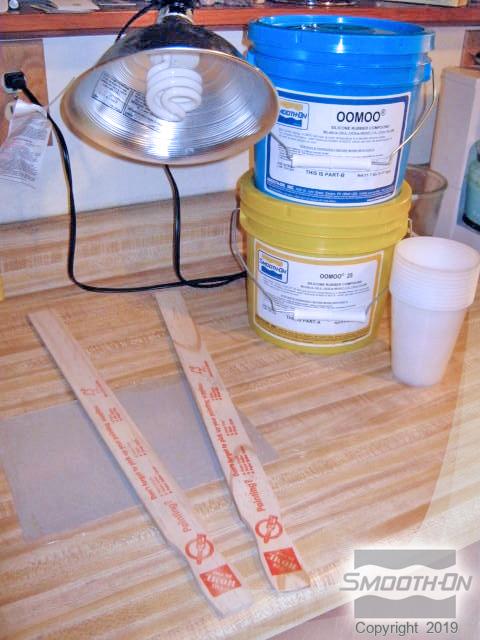

1 - OOMOO 25 silicone rubber will be used to create the trout soap mold. Plan ahead so that you have all your necessary supplies such as mixing sticks, mixing containers, etc.

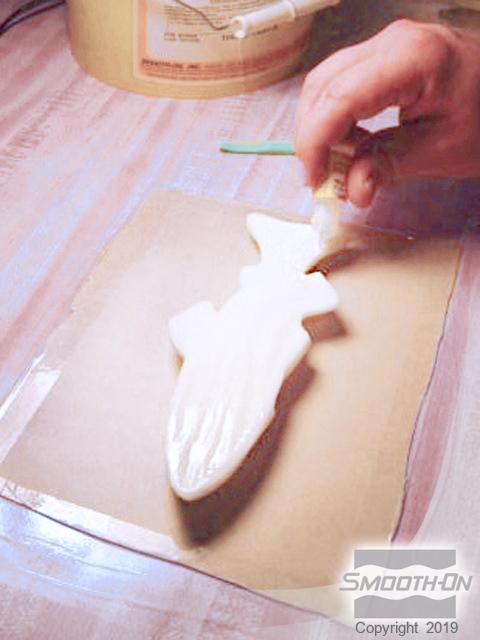

1 - OOMOO 25 silicone rubber will be used to create the trout soap mold. Plan ahead so that you have all your necessary supplies such as mixing sticks, mixing containers, etc. 2 - Tape down a piece of paperboard to create a flat base. This will also help to protect your work surface.

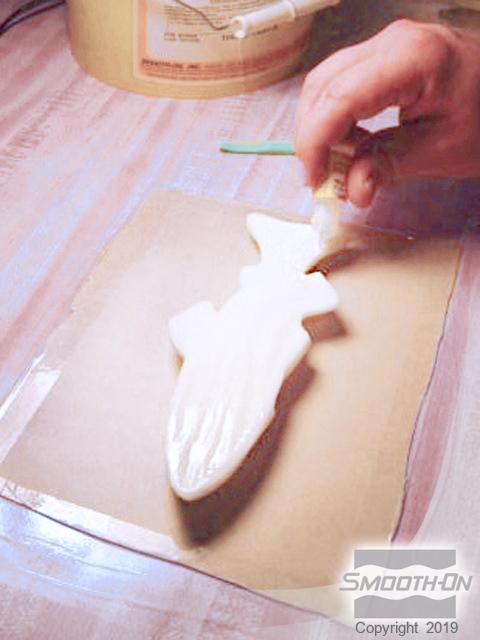

2 - Tape down a piece of paperboard to create a flat base. This will also help to protect your work surface. 3 - Using super glue, secure the trout original to the base.

3 - Using super glue, secure the trout original to the base. 4 - Be sure your base is large enough to allow a minimum of 0.5'' on all sides of your original to create your mold wall.

4 - Be sure your base is large enough to allow a minimum of 0.5'' on all sides of your original to create your mold wall. 5 - A piece of corrugated cardboard is used to create a mold wall. Flex the cardboard so that it assumes the approximate shape of the master mold.

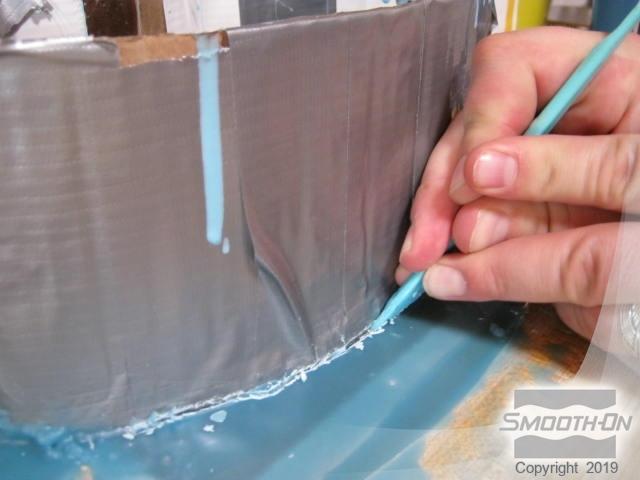

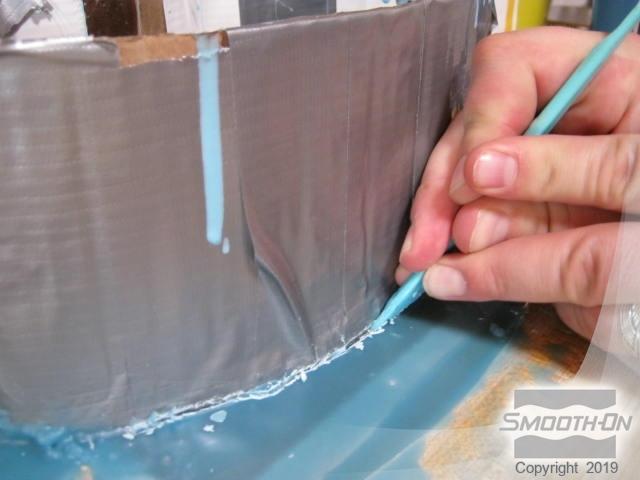

5 - A piece of corrugated cardboard is used to create a mold wall. Flex the cardboard so that it assumes the approximate shape of the master mold. 6 - Seal the mold wall with duct tape to form a uniform surface that is not porous.

6 - Seal the mold wall with duct tape to form a uniform surface that is not porous. 7 - Center your mold wall around the original.

7 - Center your mold wall around the original. 8 - Seal the bottom of the mold wall to the base using melted wax to prevent the mold rubber from leaking out.

8 - Seal the bottom of the mold wall to the base using melted wax to prevent the mold rubber from leaking out. 9 - OOMOO 25 silicone rubber has a mix ratio of 1 part A to 1 part B by volume.

9 - OOMOO 25 silicone rubber has a mix ratio of 1 part A to 1 part B by volume. 10 - Combine equal parts of A and B into a larger mixing container.

10 - Combine equal parts of A and B into a larger mixing container. 11 - Thoroughly mix part A and B until there are no color streaks. OOMOO 25 does not require vacuum degassing. OOMOO 25 has a pot life of 15 minutes.

11 - Thoroughly mix part A and B until there are no color streaks. OOMOO 25 does not require vacuum degassing. OOMOO 25 has a pot life of 15 minutes. 12 - Pour rubber into the lowest part of the mold in a long, thin stream allowing it to rise over the model and seek its own level. Let cure for at least 75 minutes.

12 - Pour rubber into the lowest part of the mold in a long, thin stream allowing it to rise over the model and seek its own level. Let cure for at least 75 minutes. 13 - When rubber is fully cured, break the wax seal in order to separate the mold wall from the base.

13 - When rubber is fully cured, break the wax seal in order to separate the mold wall from the base. 14 - Lift the mold wall away from the mold rubber. You can save it in order to make additional molds.

14 - Lift the mold wall away from the mold rubber. You can save it in order to make additional molds. 15 - Demold the trout original from the cured mold.

15 - Demold the trout original from the cured mold. 16 - The OOMOO 25 mold reflects perfect detail from the original.

16 - The OOMOO 25 mold reflects perfect detail from the original. 17 - Dozens of trout molds have been made using OOMOO 25 for production soap casting. Thousands of pieces of soap have been cast into these OOMOO molds.

17 - Dozens of trout molds have been made using OOMOO 25 for production soap casting. Thousands of pieces of soap have been cast into these OOMOO molds. 18 - The soap easily demolds from the OOMOO mold without the need for any release agent.

18 - The soap easily demolds from the OOMOO mold without the need for any release agent. 19 - Completed ''Trout Soap on a Rope'' is ready to be packaged and shipped!

19 - Completed ''Trout Soap on a Rope'' is ready to be packaged and shipped!