Mold Max® tin-catalyzed mold making rubbers are known around the world as work horse silicones. They are the backbone of production casting shops everywhere and are great for casting a variety of materials. For casting resins, nothing lasts longer in production. For most high-tear tin cure silicones, vacuuming the material to minimize air bubbles is required. For people that don't own a vacuum pump and vacuum chamber, however, spending $800 - $1,000 can be a barrier to using these materials.

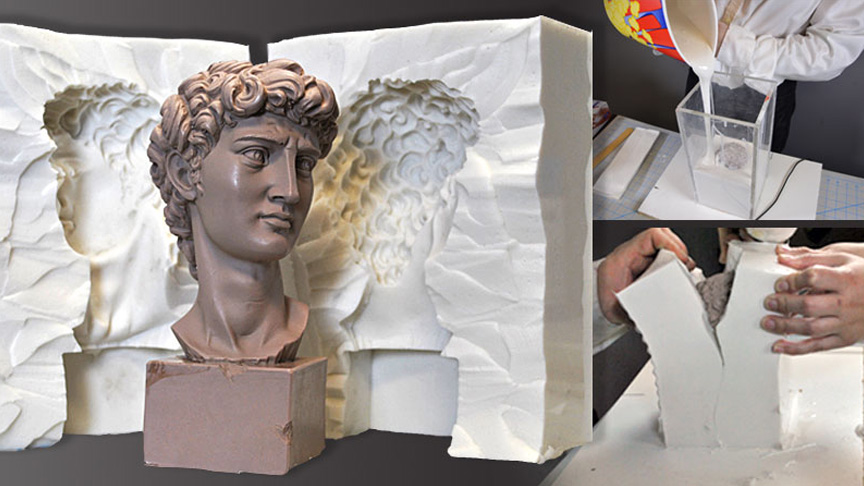

No Vacuum Required – Mold Max® 14NV is a high-tear strength tin-catalyzed silicone rubber that does not require vacuum degassing. It is measured 100A:10B by weight (a gram scale is required). Liquid rubber pours easily and flows well over any surface.

4 Hours Fast – Pot life is 45 minutes and the cure time is 4 hours at room temperature, which is good news for people that need to turn it around in a hurry.