Assisting School Age Kids To Excel In Science Competition With Smooth-On Materials

The amazing part of this case study is that the designers of the robot, who made the molds and cast the wheels, are a group of middle school and high school students from the Philadelphia, PA, area, ages 12 - 17 years old, who have designed a wheel configuration using Smooth-On rubbers and plastics. Their "Universal Wheel Design" allowed the Royal Assault Squad to excel in this science competition.

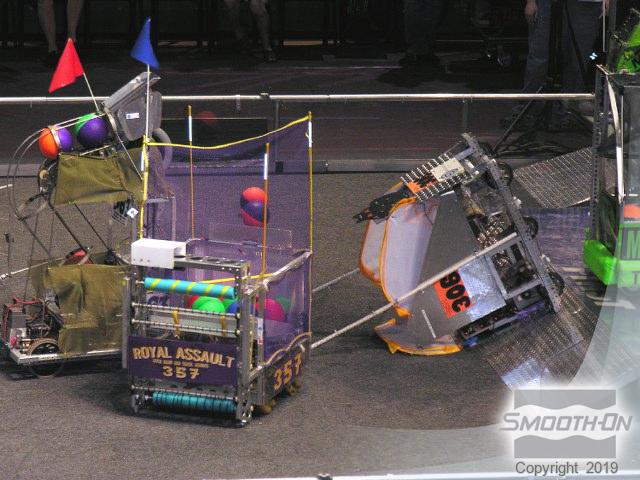

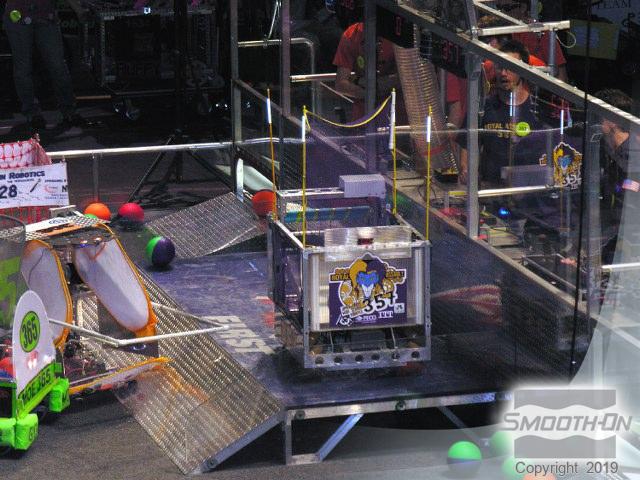

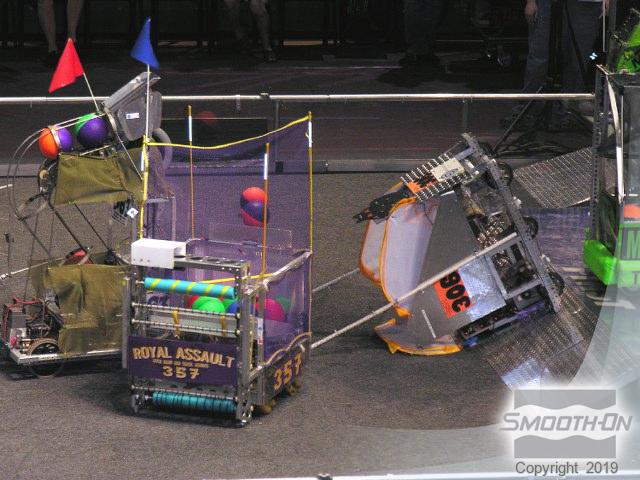

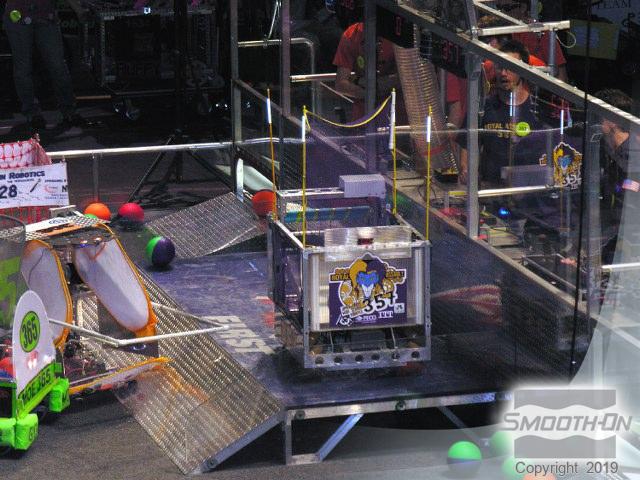

Part of the “Royal Assault - Team 357” from Philadelphia with their robot creation. You can see the urethane wheels at bottom.

Part of the “Royal Assault - Team 357” from Philadelphia with their robot creation. You can see the urethane wheels at bottom. Roller wheel castings made of Smooth-On's urethane rubber are attached to the wheel hubs.

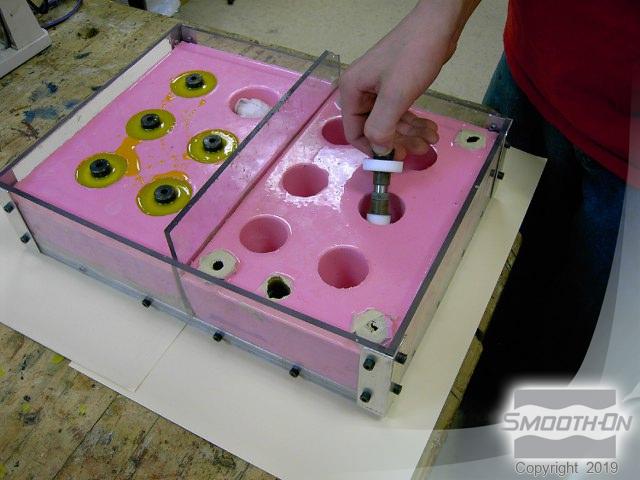

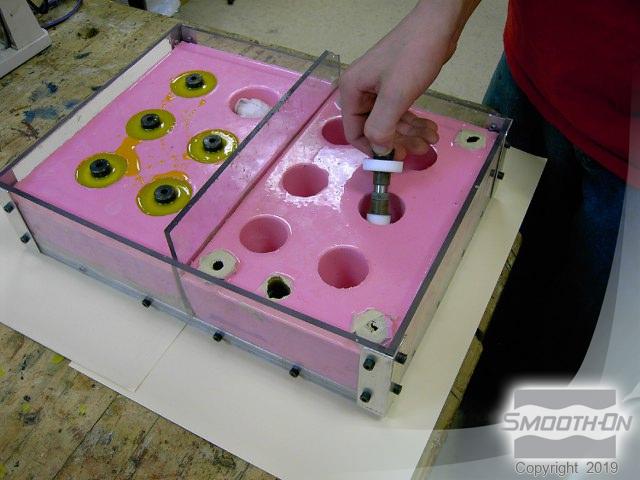

Roller wheel castings made of Smooth-On's urethane rubber are attached to the wheel hubs. Mold Max 30® silicone molds are used to cast PMC-790® urethane around a metal/nylon ring core.

Mold Max 30® silicone molds are used to cast PMC-790® urethane around a metal/nylon ring core. Molds of the original SLA models made using Mold Max 30®

Molds of the original SLA models made using Mold Max 30® Finished wheels.

Finished wheels. Students prepare their robot for battle. Remotely navigate your robot and be the first to ascend the winner's platform.

Students prepare their robot for battle. Remotely navigate your robot and be the first to ascend the winner's platform. On the way to the winner's platform, you'll be challenged by competitors. It's overturn (kill) or be overturned (killed). Royal Assault 357 overturns a competitor and then . . .

On the way to the winner's platform, you'll be challenged by competitors. It's overturn (kill) or be overturned (killed). Royal Assault 357 overturns a competitor and then . . . ...fights to claim its place on the winner’s platform.

...fights to claim its place on the winner’s platform. The unique winning wheel design has ramifications far beyond Team 357's robot world. Several Industrial Corporations have expressed interest in the unique wheel configuration.

The unique winning wheel design has ramifications far beyond Team 357's robot world. Several Industrial Corporations have expressed interest in the unique wheel configuration.