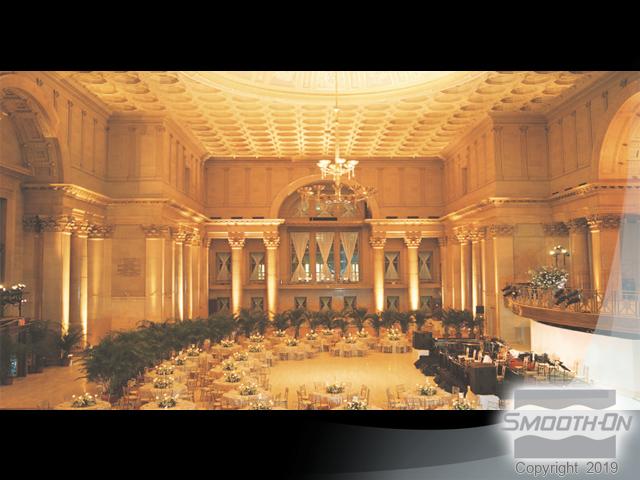

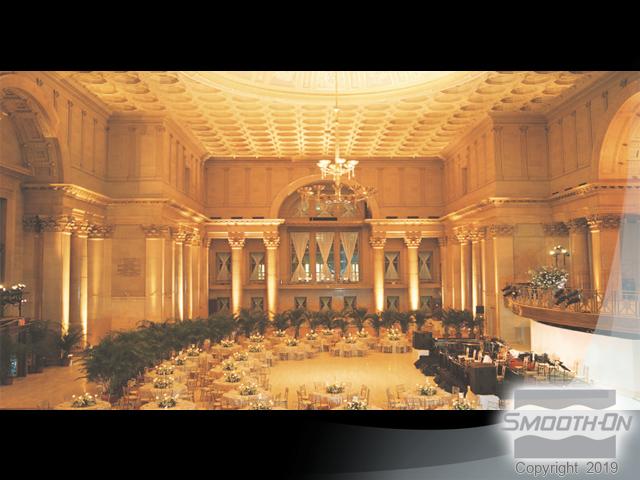

Constructed in 1842, 55 Wall Street in Lower Manhattan is a building rich in history. It was the former site of The Merchant's Exchange, The New York Stock Exchange, and The New York Customs House. In 1899 the building was sold to the National City Bank, which renovated and reconstructed the main hall in a Corinthian style.

A century later, the ornate plaster ornamentation on the ceiling was in need of considerable restoration. Hyde Park Mouldings of New York was charged with replacing the deteriorating plasterwork for the building’s new tenant – the luxurious Regent Wall Street Hotel.

Smooth-On's Brush-On® 40 urethane rubber became the material of choice for this historical project. Molds were made of undamaged sections of plasterwork, which could then be cast to replace similar damaged pieces.

90 feet above the ballroom floor, the ceiling of The Regent Hotel in downtown Manhattan was in need of a facelift.

90 feet above the ballroom floor, the ceiling of The Regent Hotel in downtown Manhattan was in need of a facelift. The historic plaster ornamentation had deteriorated over time.

The historic plaster ornamentation had deteriorated over time. Hyde Park Moulding artisan examines preserved sections of archway prior to the mold making process beginning.

Hyde Park Moulding artisan examines preserved sections of archway prior to the mold making process beginning. Super Seal® sealing agent and Universal Mold Release was applied to all surfaces. Smooth-On's Brush-On® 40 urethane rubber is then applied.

Super Seal® sealing agent and Universal Mold Release was applied to all surfaces. Smooth-On's Brush-On® 40 urethane rubber is then applied. The first layer of Brush-On® rubber is applied in a very thin coat.

The first layer of Brush-On® rubber is applied in a very thin coat. Brush-On® 40 can be applied to vertical or even inverted surfaces.

Brush-On® 40 can be applied to vertical or even inverted surfaces. SO-Strong® urethane pigments are added to every other layer.

SO-Strong® urethane pigments are added to every other layer. Result: color pigmenting ensures thorough coverage over the previous layer and helps eliminate thin spots in cured rubber mold.

Result: color pigmenting ensures thorough coverage over the previous layer and helps eliminate thin spots in cured rubber mold. Architectural accents are often very complex, making them difficult to reproduce.

Architectural accents are often very complex, making them difficult to reproduce. Brush-On® 40 will reflect the smallest detail on even the most complex original.

Brush-On® 40 will reflect the smallest detail on even the most complex original. One mold maker continues adding layers of rubber, while another prepares the surrounding surface.

One mold maker continues adding layers of rubber, while another prepares the surrounding surface. 4 layers of rubber are required to reach a recommended thickness of 3/8'' (1cm).

4 layers of rubber are required to reach a recommended thickness of 3/8'' (1cm). Once a suitable thickness has been attained, all layers are allowed to cure overnight.

Once a suitable thickness has been attained, all layers are allowed to cure overnight. The following day a rigid support shell is applied.

The following day a rigid support shell is applied. Completed Brush-On® 40 rubber mold is seated in the support shell and ready for casting.

Completed Brush-On® 40 rubber mold is seated in the support shell and ready for casting. Finished molds are used to cast plaster to create replacement ornamental ceiling sections. Sections are installed at the landmark 55 Wall Street ballroom.

Finished molds are used to cast plaster to create replacement ornamental ceiling sections. Sections are installed at the landmark 55 Wall Street ballroom. The results: This badly damaged plasterwork was beautifully restored to its original grandeur.

The results: This badly damaged plasterwork was beautifully restored to its original grandeur.