Moen®, Inc. (based in Olmstead, OH) is one of the world’s leading manufacturers of bath and shower fixtures. Bringing a new fixture concept to market is a group effort and begins at Moen’s design center. Development involves several departments including Moen’s prototype team headed by Mr. Ed Solensky who is an experienced mold maker and caster.

Mr. Solensky uses the full spectrum of Smooth-On tin and platinum-based silicone rubbers as well as Smooth-Cast and TASK® plastics to develop and refine proposed designs.

The following photo sequence begins with an original SLA model being extracted from a two piece Sorta Clear® 40 silicone rubber mold. Sorta Clear® is a high-tear platinum silicone used by many professional prototype designers because it offers the advantage of letting you see your model as you are cutting the rubber and minimizing damage to the model.

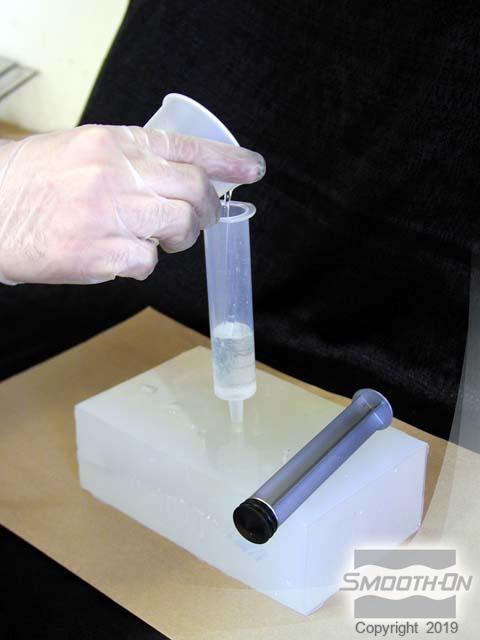

TASK® 2 urethane plastic is a premium urethane resin that offers higher performance properties vs. general purpose casting resins. The resin is mixed and injected into the mold with a syringe to produce a precise part that will be finished and presented for pre-production preparations to ultimately be sold as the Moen® “Icon Pulse” shower head.

Moen Uses Smooth‑On To Spark Development