Nature's Best Candle Co. was experiencing widespread mold failure when casting their candles. Their custom blend of bees wax and paraffin resulted in a product that melted at 225°F / 107°C. At these temperatures their latex and urethane rubber molds were not lasting very long.

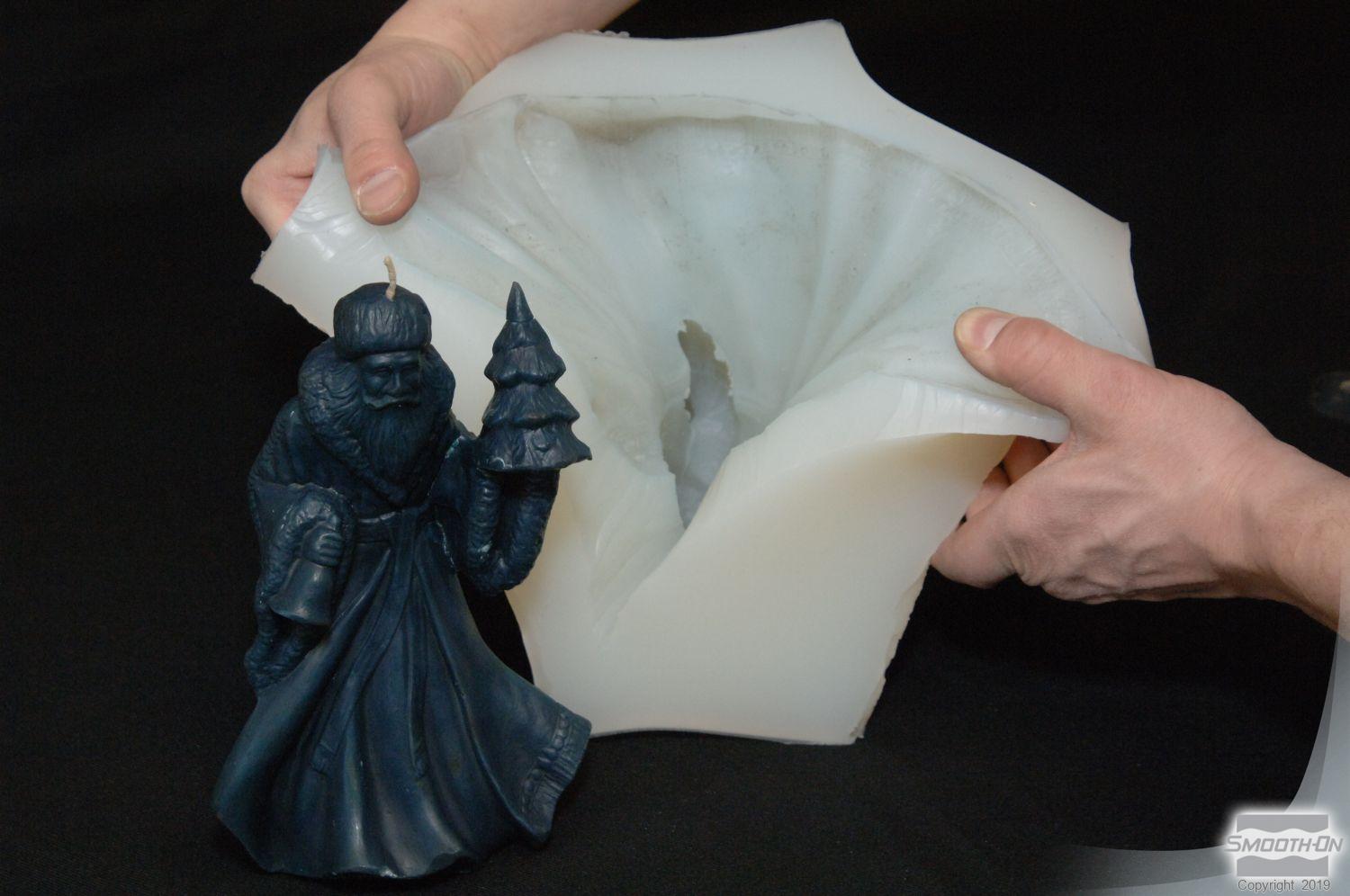

Nature's Best experimented with a variety of mold rubbers and decided to change its production entirely to Smooth-On platinum silicone rubbers.

"We were blown away by the tear strength these rubbers have to handle shapes like pine cones and other deep detail models. You simply can't tear this stuff and we have not had one problem with a mold failing do to the wax being too hot. Our investment in this silicone has paid off one hundred fold." - Asher Rothstein, President, Nature's Best Candle Co.