Smooth-On sells thousands of cans of aerosol release agent every year. Some customers have purchased 50 or 60 cases of release agent for a single project, unaware that these release agents are available in liquid or "bulk" form.

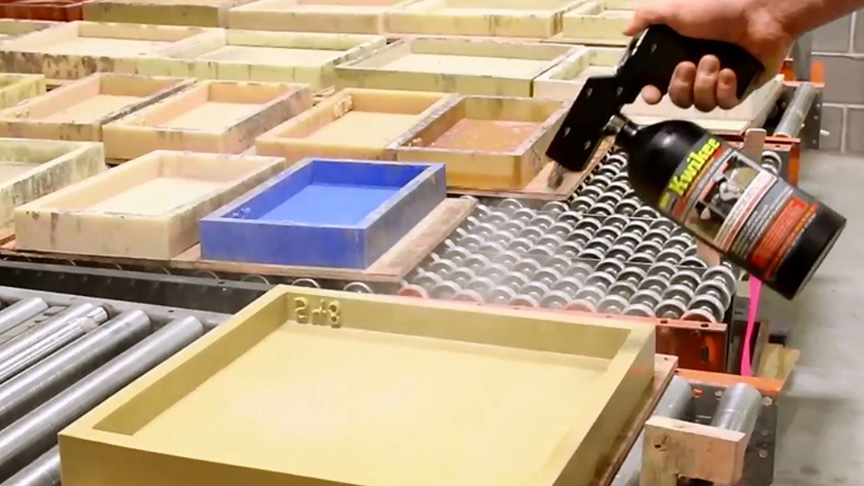

While convenient, aerosols are an inefficient and expensive way to deliver release agent compared to brushing on or spraying on liquid releases. We are introducing the Kwikee™ sprayer as an economical alternative to aerosols. It is a faster, labor-saving way to cover large models or molds and delivers sealing agent or release agent in a fine mist.

For large projects, the Kwikee™ eliminates the problem of aerosol plume in the air. For the average "small-time" mold maker/caster, aerosols will still represent the best value. For production settings, the cost of the Kwikee™ sprayer will pay for itself after a single use in terms of material cost and labor savings you'll experience using liquid release agents vs. aerosols.

Make sure you observe all safety precautions when using the Kwikee, especially when spraying flammable sealers and release agents.