How To Make a Brush On Mold Using Mold Max™ STROKE

Overview

Mold Max™ STROKE is a brushable tin silicone rubber that self-thickens for making fast brush-on molds of almost any model. Properly applied, it will hold a vertical surface and will reproduce the finest detail. Mixed 100A:10B by weight, rubber quickly develops thixotropy and can be applied with a brush or spatula. Working time is 20 minutes, re-coat time is 45 minutes and cure time after the final layer has been applied is 16 hours at room temperature.

Mold Max™ STROKE silicone will not stick to most surfaces and will cure with negligible shrinkage to a strong, flexible Shore 30A rubber. 4 thin layers is all that is necessary to make a strong and durable production mold for casting wax, gypsum, concrete, or resins (urethane, polyester, etc.). Applications include reproducing sculpture, architectural restoration, making candle molds, casting pewter, etc.

Distinct Material Benefits:

- Save money! – use less material than block molds

- Relative convenience – two-part system eliminates need for third component thixotropic additive

- Less expensive than platinum-cured systems

- Not nearly as susceptible to cure inhibition – will cure against sealed sulfur clay original

- Not heat sensitive – full work time in warm environment

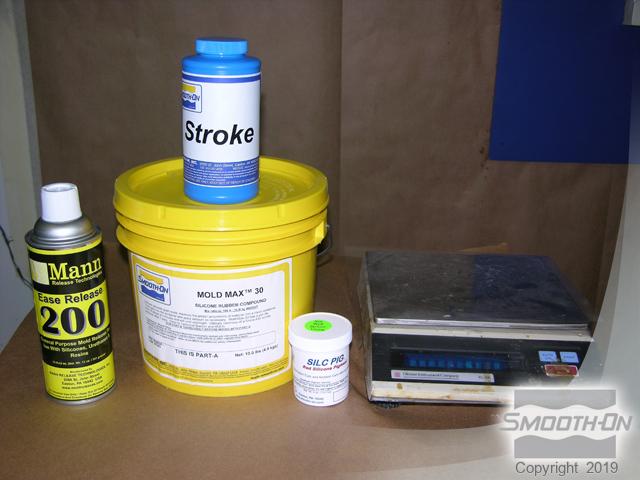

Materials Used in this Tutorial

- Mold Max™ Stroke

- Ease Release™ 200

- Mixing Container

- Mixing Sticks

- Accurate Gram Scale

- Silc-Pig

- Paint Brush

- Sil-Poxy™

- Thi-vex™

- Plasti-Paste™

- duoMatrix™ Neo

Step 1: Gathering Materials

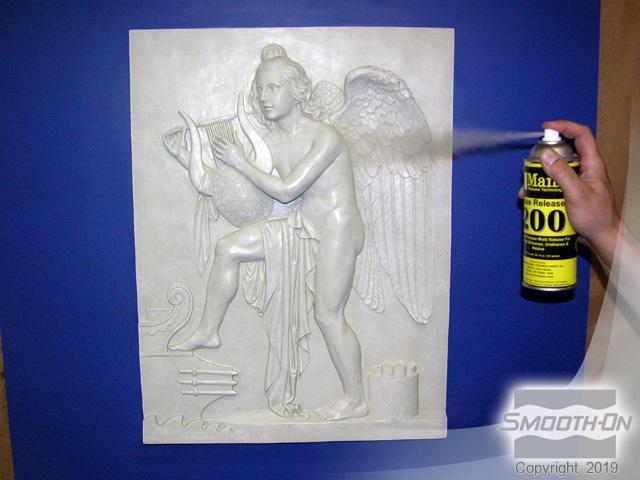

This original relief sculpture has fine detail and some undercuts, so we must be sure to choos the right materials. Mold Max® Stroke® is a brushable tin-catalyzed silicone perfect for applying to vertical or even inverted surfaces. Safety First!: Wear eye protection and gloves when working with mold making materials.

Step 2: Preparing, Dispensing and Applying Mold Max™ STROKE

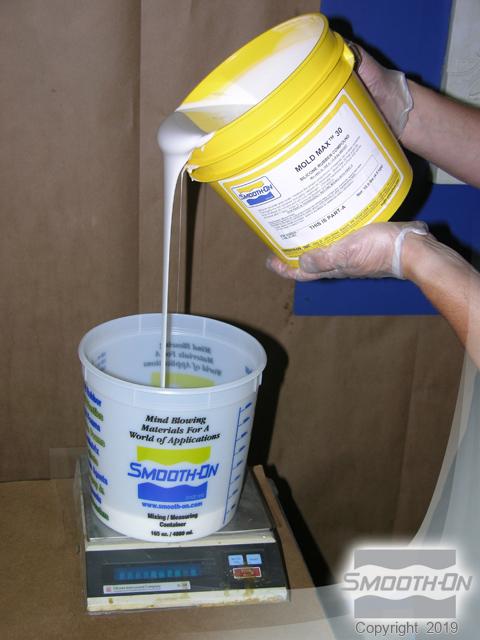

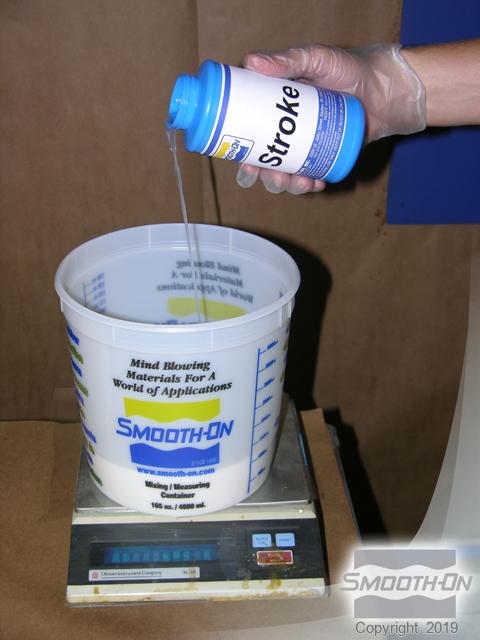

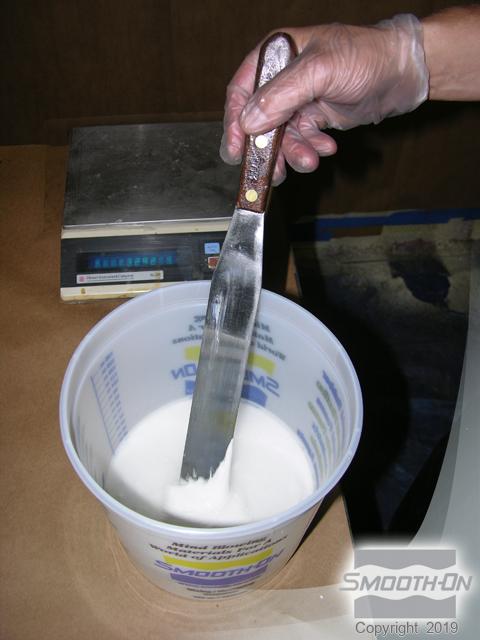

Begin by spraying a thorough coat of Ease Release™ 200 release agent over the original model. Mold Max™ STROKE is measured 100 Parts A to 10 Parts B by weight. First measure out the A component, and then add an appropriate amount of the B component. Thoroughly mix Parts A and B together, making sure to scrape the sides and bottom of the container several times.

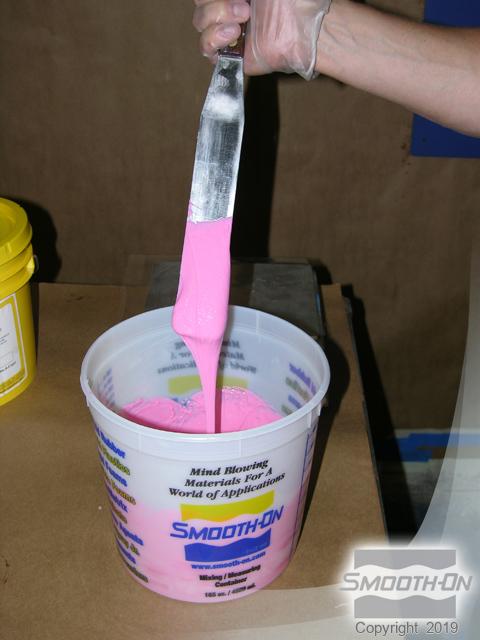

Mold Max™ STROKE is white in color, and since the original model is also white, adding some Silc-Pig™ Red silicone pigment to the Stroke® will ensure thorough coverage when the rubber is applied. Thoroughly mix Silc-Pig™ Red into the silicone and continue mixing until no color striations are present and the silicone is a solid pink color.

Begin applying Mold Max™ STROKE to the original. It is important that the first layer of a brush-on mold be applied in a thin coat. This helps eliminate the possibility of entrapping air bubbles. Be sure to look at the model from all angles to ensure thorough coverage. Brush silicone around the outside of the piece to create a flange.

After the first layer has partially cured (approximately 45 minutes), mix and apply a second layer of Mold Max™ STROKE. This time, do not add pigment as the white rubber contrasts well with the first layer and we can again ensure thorough coverage. Cover the entire model and continue building the flange. This layer can be applied slightly thicker than the first.

We will continue on for a total of four layers.

Step 3: Installing Keys into Mold

Mold Maker's Tip: Mold keys are used to help align a rubber mold into a rigid support shell.

Mold Max® silicone rubber keys are cast into plastic ice cube trays. Sil-Poxy® silicone adhesive can be used to adhere the keys to Mold Max® Stroke®. Once the second layer has partially cured (approximately 45 minutes), adhere the keys to the outer edges of the mold. Allow Sil-Poxy® to fully cure (12 minutes) before applying the next layer of Mold Max® Stroke®.

Step 4: Adding a Thickened Layer of Mold Max™ STROKE

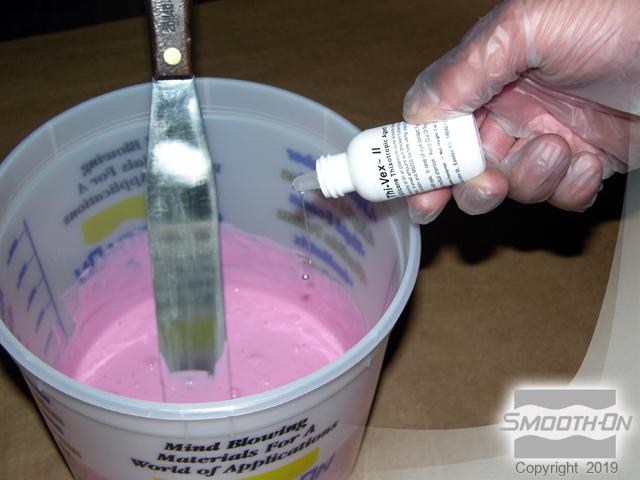

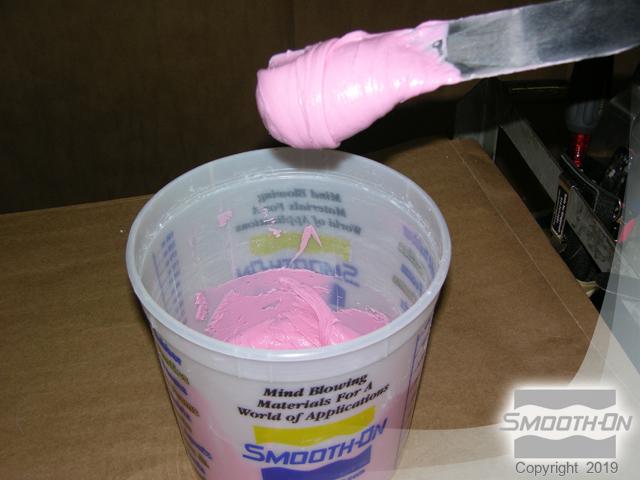

Now, mix another batch of Mold Max™ STROKEwith Silc-Pig™ pigment added. Add Thi-Vex™ silicone thickener to thicken the batch. Use the thickened rubber to quickly fill in undercuts and smooth out sharp edges of the original. Allow the thickened layer to partially cure for 45 minutes before applying the next layer.

Step 5: Apply Silicone to Build Up Mold Thickness

Mix and apply another layer with pigment added, but this time do not add thickener. Be sure to completely cover the model and build flange. Allow this layer to partially cure for 45 minutes.

Step 6: Applying Final Layer of Mold Max™ STROKE

Mix and apply a fourth layer of Mold Max™ STROKE with no pigment added, covering the entire model and flange. The rubber mold should be approximately 3/8'' (1 cm) thick. Allow the entire Mold Max™ STROKE mold to fully cure (16 hours). Using a sharp razor knife, cut the excess silicone from the outer edge of the mold, creating straight edges and squaring off all of the corners.

Step 7: Preparing and Applying 1st Layer of Plasti-Paste™

Spray the rubber mold and surrounding surface with Ease Release™ 200 to separate the support shell from the mold. In some cases, Smooth-On's Sonite™ Wax may be necessary to release surrounding surfaces from the support shell.

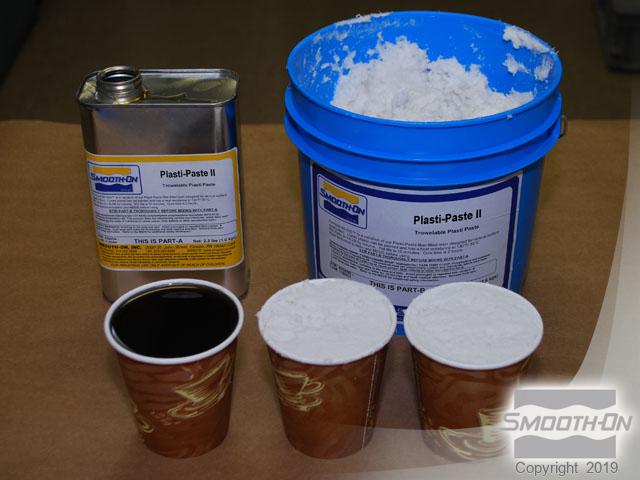

Creating the rigid support shell: Smooth-On's Plasti-Paste™ is a trowelable urethane resin designed to be used for support shells. It is mixed 1 Part A (liquid) to 2 Parts B (paste). Combine 1A:2B and mix thoroughly until there are no color striations, making sure to scrape the sides and bottom of the mixing container. Apply Plasti-Paste™ over the cured Mold Max™ STROKE, covering the entire mold with Plasti-Paste™.

Important: Plasti-Paste™ has a working time of 8-10 minutes. Do not mix more material than can be applied in this amount of time.

Step 8: Applying 2nd Plasti-Paste™ Layer

Mix and apply more Plasti-Paste™ as needed. Be sure to apply material beyond the edge of the silicone mold. Apply at least 3/8'' (1 cm) thickness, making sure the rubber mold is thoroughly covered. Larger molds may require added thickness for support shell stability.

Attach wooden blocks to the support shell with additional Plasti-Paste™. These blocks will help level the mold during casting and allow for easier handling. Once all the Plasti-Paste™ has fully cured (approximately 90 minutes), carefully remove the support shell from wall.

Step 9: Demolding

Plasti-Paste™ is strong, durable and lightweight. The edges of the support shell can be sharp, so you should sand the Plasti-Paste™ to make handling safer and easier. Peel the Mold Max™ STROKE mold away from the original piece and seat the rubber mold into the support shell. The mold keys previously added will make aligning the mold with the shell very easy. Once seated, check the level across different axes.

Step 10: Dispensing and Pouring duoMatrix™ NEO

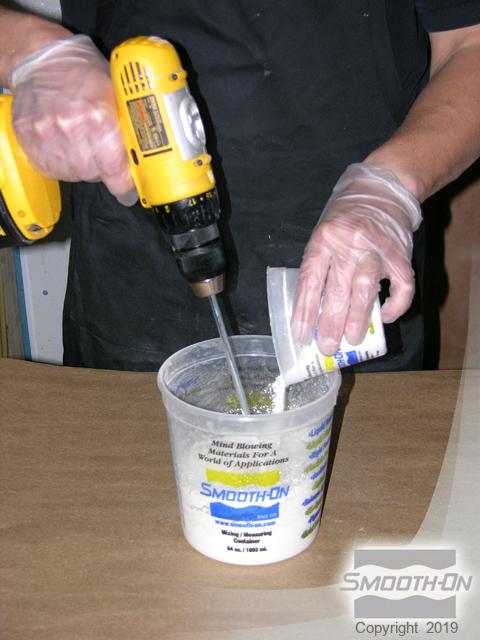

Casting a lightweight reproduction: duoMatrix™ NEO is a polymer modified gypsum system that is perfect for casting strong yet lightweight architectural elements. It is mixed 100 Parts A (powder) to 50 Parts B (liquid). Using a drill mixer, combine the powder with the liquid and mix thoroughly, pausing occasionally to scrape the sides and bottom of the container. Once thoroughly mixed, pour the mixture into the mold. This first batch will be used to make a ''gel coat'' on the surface of the mold. Brush the gel coat over the surface of the mold to create a thin layer of duoMatrix™ NEO.

Step 11: Applying the 2nd Layer of duoMatrix™ NEO

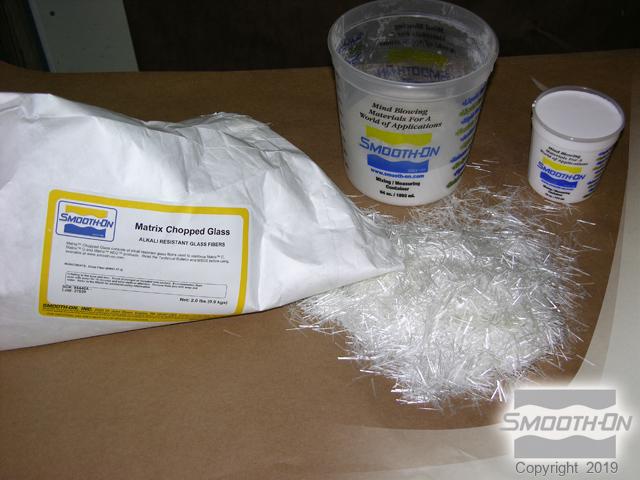

Smooth-On's Matrix™ Chopped Glass is the perfect chopped fiberglass for layup applications using Matrix products. It adds great strength and durability to a NEO casting.

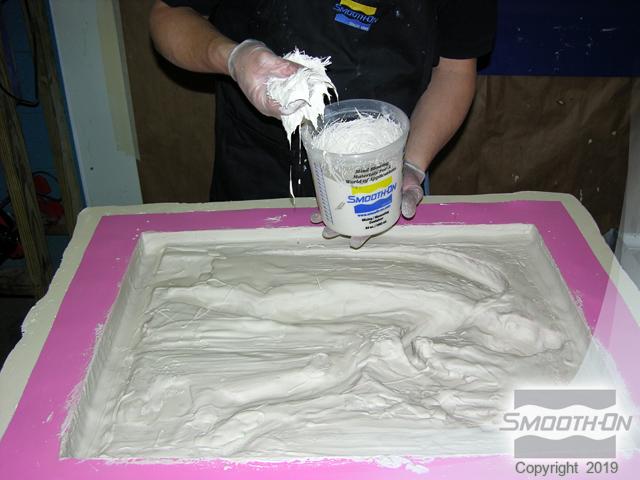

Matrix™ Chopped Glass is added as a percentage to the system. For best results, 6% chopped fiber by weight should be added to the mix. Soaked glass fiber can be laid up by hand behind the first coat of NEO. Push the chopped glass mixture into deep areas of mold. Thorough coverage will give the piece the greatest strength and durability.

Step 12: Applying 3rd Layer of duoMatrix™ NEO and Demold Casting

Mix and apply a second batch of duoMatrix™ NEO with no fiber added. Brush Matrix™ over the back of the entire casting. Once the casting has fully cured (about 1 hour), carefully turn the mold upside down and remove the support shell. Peel back the Mold Max™ STROKE silicone rubber mold from the Matrix casting. Mold Max™ STROKE reflects the perfect detail captured from the original model. duoMatrix™ NEO makes for a perfect casting as it is thin, strong, and lightweight.

The perfect reproduction: A Mold Max™ STROKE mold can be used many times to reproduce exact replicas of just about any original model.