How To Create Lightweight Theatrical Costume Armor

Overview

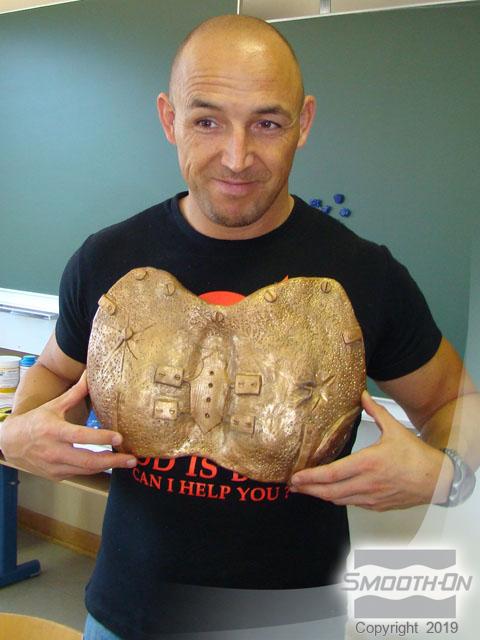

Andreas Moravec is a moldmaker and makeup artist based in Austria. In this tutorial, Andreas demonstrates a technique for creating '300' style theatrical armor using Rebound™ 25 silicone and Smooth Cast® resins.

Using Smooth Cast® 325 pigmented with So-Strong® black tint produces a very lightweight, yet impact resistant piece.

Visit Andreas' website here: http://www.andreasmoravec.at

Materials Used in this Tutorial

- Mixing Containers

- Mixing Sticks

- Paint Brushes

- Smooth-Cast® 325

- So-Strong

- Rebound™ 25

- Alja-Safe®

- Gypsum Bandages

- Plasti-Paste®

- Cast Magic®

Step 1: Working with Alja-Safe™

Alja-Safe™ alginate is used to take an impression of the actor's chest. Gypsum bandages are then used to back up the alginate and provide support. The Alja-Safe™ captures every detail of the actor and a gypsum cast is made from the Alja-Safe™ mold.

Step 2: Creating Armor

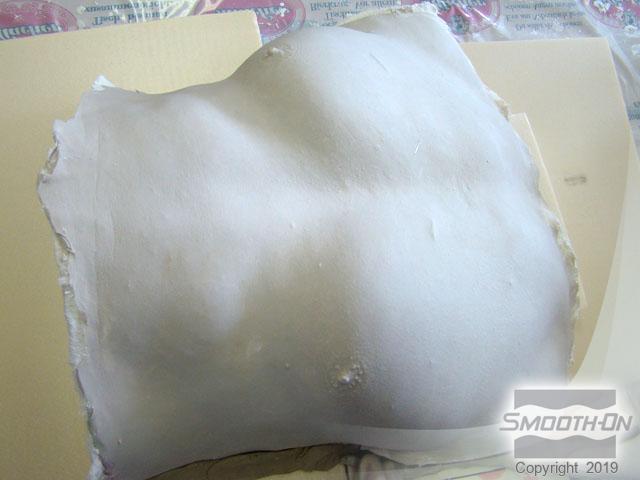

The armor detail is sculpted onto the gypsum positive using an oil-based clay. Moldmakers then apply a thin coat of Rebound® 25 rubber. A thickness of 3/8'' (1cm) of Rebound® 25 silicone is brushed onto the sculpt. Plasti-Paste® is then applied on top of the cured Rebound® 25 to form a support shell and allowed to cure.

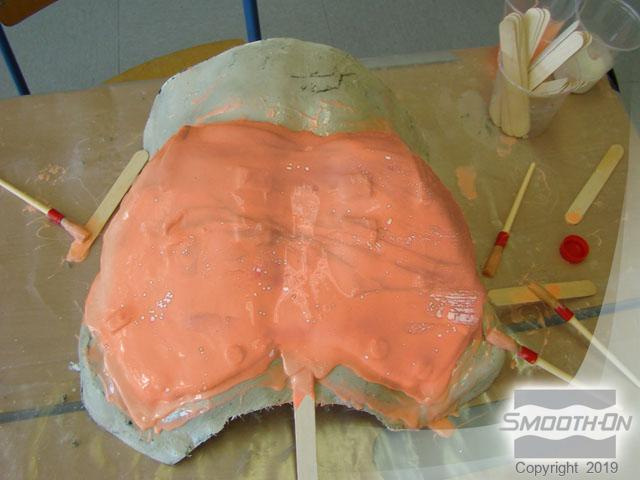

Step 3: Casting your Armor

The mold is opened, revealing that all of the detail has been catured in the Rebound® 25 silicone. Cast Magic® powder is brushed onto the mold surface. Smooth Cast® 325 is pigmented black using So-Strong® tints and brushed into the mold. The Smooth Cast® resin is allowed to fully cure for 1 hour.