How To Replace a Brass Shower Door Handle

Overview

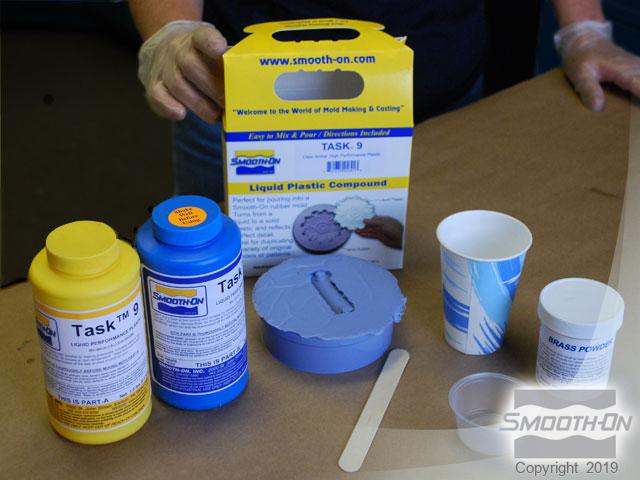

The original brass shower door handle, over time, cracked and broke. The homeowner contacted the door manufacturer for a new one and was informed that the handle was discontinued, however a custom replacement could be purchased from another company. The cost of the replacement handle was substantial. A replacement "Cold Cast Brass" handle could be molded and cast with Oomoo® 30 silicone rubber, Task® 9 performance casting resin, and Brass Metal Powder for a fraction of that cost.

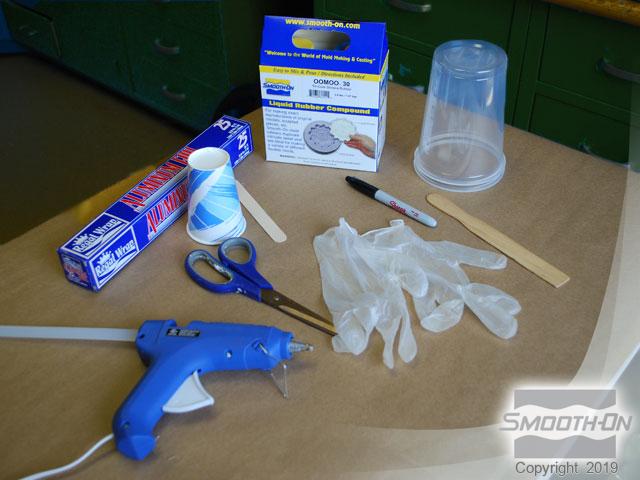

Materials Used in this Tutorial

- OOMOO 30

- Mixing Containers

- Black Marker

- Mixing Sticks

- Hot Melt Glue Gun

- Scissors

- Aluminum Foil

- Task 9

- Brass Metal Powder

Step 1: Preparing Original Piece

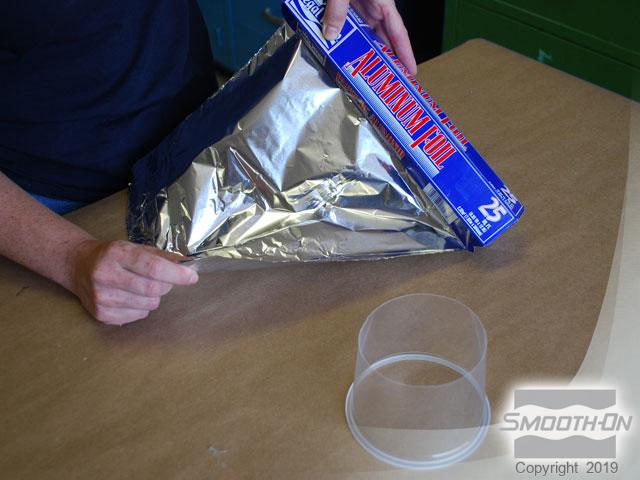

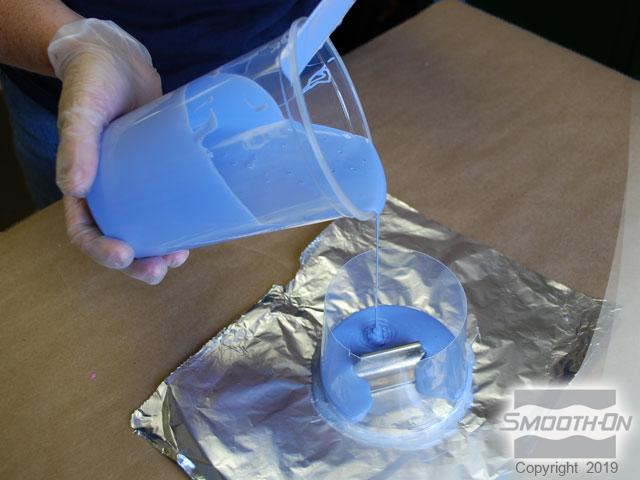

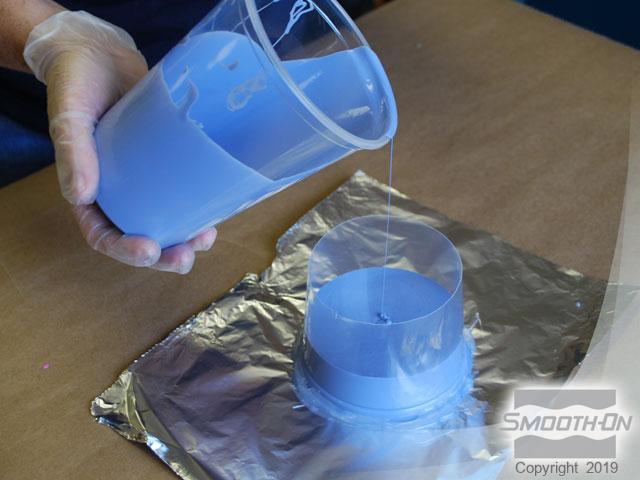

All supplies should be gathered before starting. Since the original brass handle from this example cracked a broke, a sister door handle is removed from another door to use in making the mold. Cut a plastic deli cup to size for the mold container. Use aluminum foil as a base for the mold container. Hot glue the good handle to the aluminum foil by applying a bead of glue around the outside edge and firmly press the handle into the center of the aluminum sheet. Center the deli cup around the handle and glue it down, making sure that the mold container has 1/2 inch clearance on all sides, including the top.

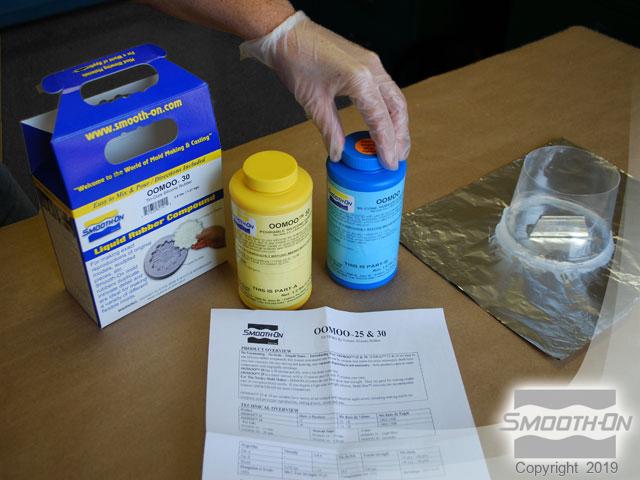

Step 2: Dispensing, Mixing, and Applying OOMOO 30

Safety First: Wear vinyl gloves when working with these materials. Read the Technical Bulletin before using these products.

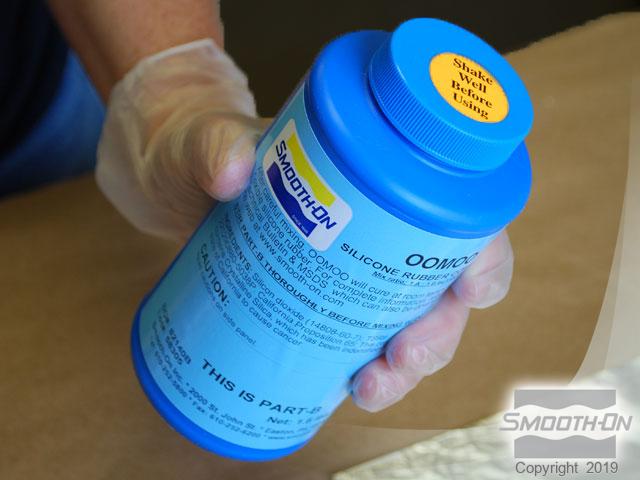

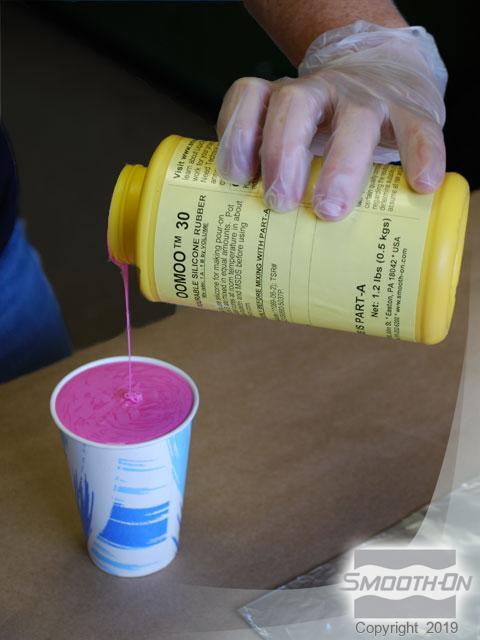

Shake Oomoo® 30 well before using. Carefully measure required amount of Oomoo® 30 Part A and then measure out an equal amount of Oomoo® 30 Part B.

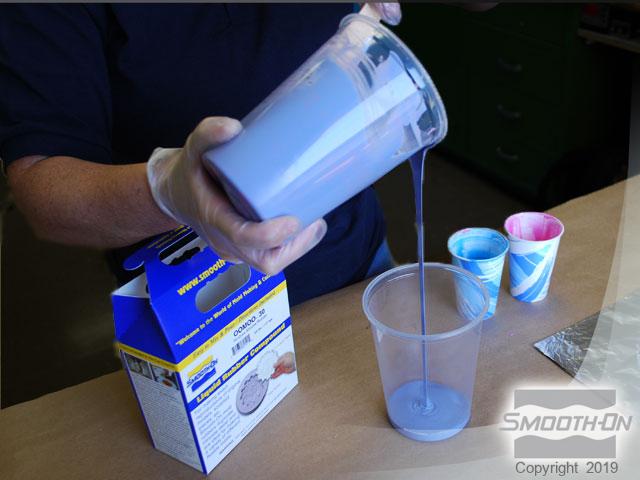

Combine Part A and B in a mixing container and mix thoroughly until a uniform color is achieved and no color streaks are visible, making sure to scrape teh sides and bottom of the container. When no color streaks are visible, transfer the mixture to a 2nd clean mixing container. Continue to mix thoroughly for an additional 1 minute. Ensure no color streaks are visible, and then slowly pour the silicone around the handle. Liquid silicone should completely cover the handle by 1/2 inch over highest point.

Oomoo® 30 requires a minimum of 6 hours to cure.

Step 3: Demold Model from Mold

Once the Oomoo® 30 is cured, remove the aluminum foil from the base. Gently remove the mold from the container and carefully remove the handle from the mold. Oomoo® 30 silicone mold rubber captures perfect detail and is ready for casting.

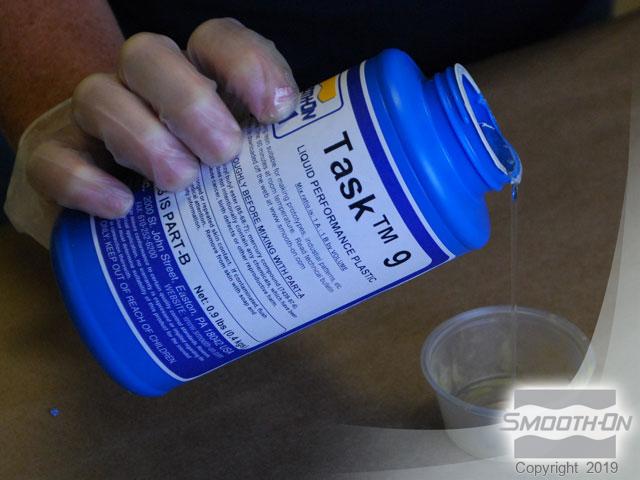

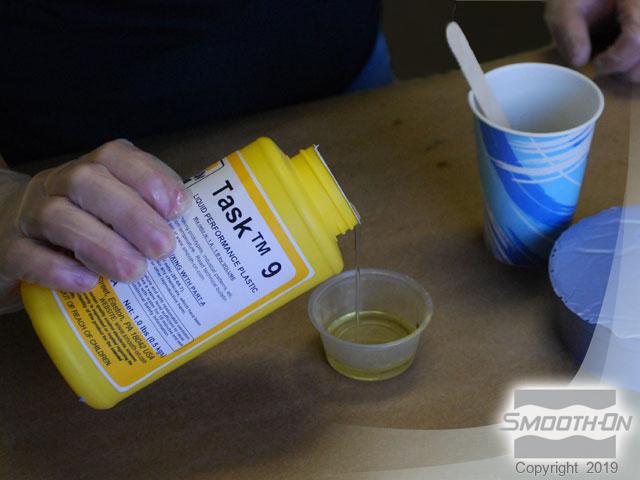

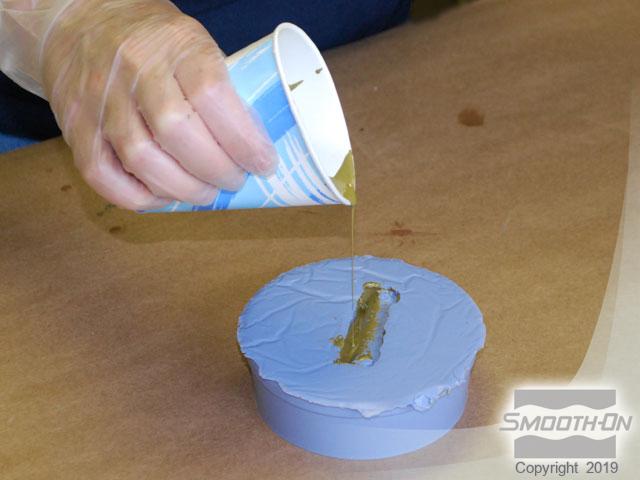

Step 4: Dispensing, Mixing, and Casting Task 9

Gather all materials needed to make the casting before you start. Mark a measuring line on a small cup as very little material will be required to make this casting. Fill Brass Metal Powder to the line and dispense into the mixing cup. Using the same measuring cup, carefully measure Task® 9 resin Part B to the line. Add the Task® 9 Part B to the mixing cup containing the Brass Powder and mix thoroughly, continually scraping the sides and bottom of the cup while mixing. Carefully measure out Task® 9, Part A. and pour into the mixing cup containing the Brass Powder and Part B. Again, mix thoroughly, scraping the sides and bottom of the container several times. Slowly pour the liquid mixture into the mold cavity until completely full.

Step 5: Demold, Finsihing, and Installing Casting.

Allow the resin to cure a minimum of 60 minutes before demolding. Use a drill to carefully clean out the screw holes. Then, use steel wool to polish teh cast replacement handle and attach to the shower door. The new handle perfectly matches the shower door trim!