How To Turn an Antique Chair from Trash Into Treasure

Overview

An antique chair is easily repaired using Smooth-Cast® 385 mineral filled casting resin and Universal® Release Agent.

Materials Used in this Tutorial

- Sulfur Free Clay

- Smooth-Cast 385

- Universal Mold Release

- Acid Brush

- Mixing Sticks

- Mixing Containers

- Gram Scale

Step 1: Preparing Model

A damaged antique chair was found at a garage sale, but the small piece of carved wood missing from the top of the chair can quickly be replaced with Smooth-Cast® 385 mineral filled resin.

First, make containment walls with pieces of modeling clay. Apply molding clay along the gap to form containment walls. Then, firmly press the modeling clay against a backing board to contain the Smooth-Cast® 385 liquid resin.

Step 2: Applying Smooth-On Materials

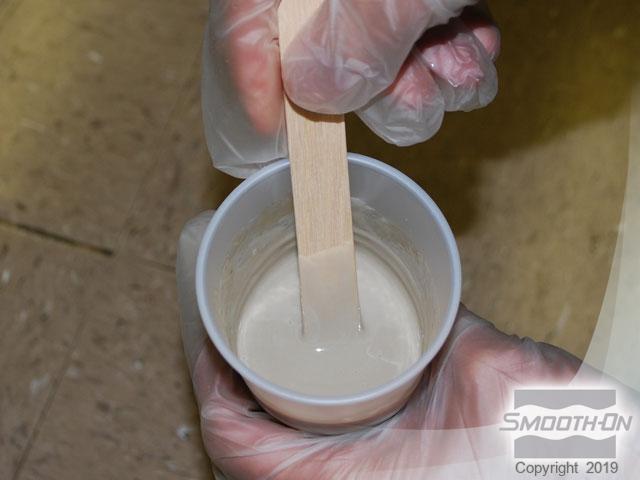

Apply Universal® Release Agent to an acid brush and brush onto the base board only. Measure Smooth-Cast® Parts A and B by weight using a gram scale, then combine by thoroughly mixing Parts A and B, making sure to scrape the sides and bottom of the mixing container several times. A and B must be mixed until a uniform color is achieved, then slowly poured into the void between the clay walls until completely full.

Step 3: Finishing Antique Piece

Allow the Smooth-Cast® 385 to cure a minimum of 2 hours before removing the clay walls. A tool may be need to remove clay from the inside surfaces. Sand the cured Smooth-Cast® 385 to match the contours of the carved chair. Smooth-Cast® 385 is now completely bonded to the wood and ready to finish. Apply Gold Leaf to the Smooth-Cast® 385 resin to match the existing chair's finish. Once the Gold Leafing is complete, apply a patina to match the existing finish as well.

The repaired area perfectly matches the existing chair. From start to finish, the repair was completed in four hours.