Fran Volz is an artist and mold maker living and working in the Chicago, IL area. He has developed new media for creating his works, including creating sculpture with foam and snow, but he always finds himself returning to a classic form – bronze.

His website describes some of the influences that continue to influence and inspire his sculptural works:

“While Volz enjoys working with different media, his real love is creating monumental statues in bronze. He likes the permanence of bronze and the classical appearance these works have. Volz has been influenced by a variety of sources. He enjoys the classical styles of such artists as Michelangelo, DaVinci, Rodin and Houdon; the whimsical subjects of Norman Rockwell; the dynamic poses of Marvel Comics superheroes and the fluid, flowing lines of Disney and Vargas characters. Like his snow sculptures, Volz likes to create bronze works that touch people. For this reason, he concentrates on human form compositions; and less on abstracts.“

This gallery features a monumental task – creating a mold from an oversized original sculpture of a Greek god. Mr. Volz found Rebound™ 25 silicone rubber to be an extremely versatile solution to this problem. He engineered a complex, multi-piece mold as a step in the ‘lost-wax’ process that would eventually transform his water-based clay original into a bronze masterpiece.

For more information about Mr. Volz’s process and to see more examples of his work, visit his website at: www.franvolzstudios.com

Fran Volz adds some finishing touches to his clay Greek god sculpture.

Fran Volz adds some finishing touches to his clay Greek god sculpture. Volz's towering figure viewed from the back.

Volz's towering figure viewed from the back. The completed sculpture is ready for the mold making process. Volz carefully plans mold making process before applying any rubber to the sculpture.

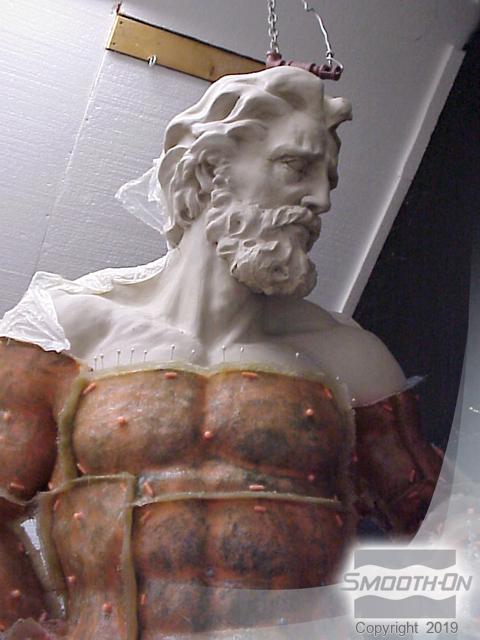

The completed sculpture is ready for the mold making process. Volz carefully plans mold making process before applying any rubber to the sculpture. Volz creates a brush-on mold using Rebound® 25 silicone rubber from Smooth-On. He creates a resin and fiberglass support jacket to give the flexible rubber a rigid structure.

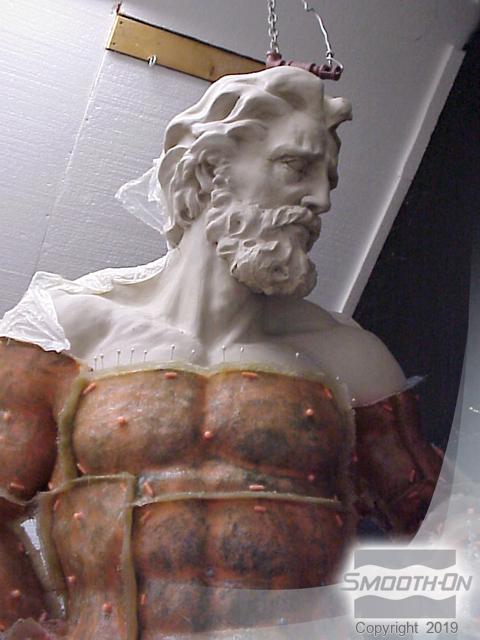

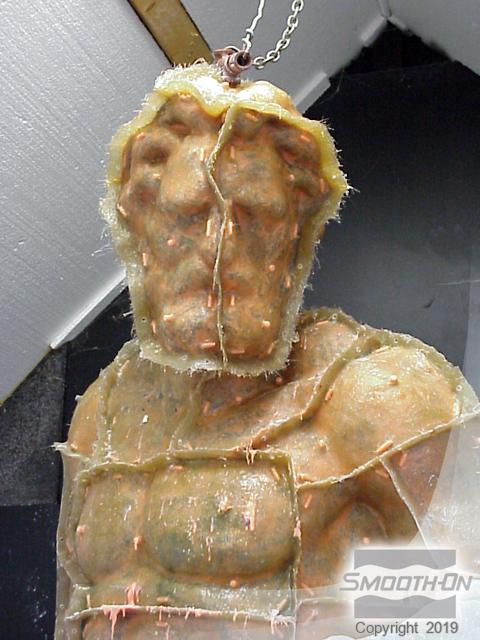

Volz creates a brush-on mold using Rebound® 25 silicone rubber from Smooth-On. He creates a resin and fiberglass support jacket to give the flexible rubber a rigid structure. The Rebound® 25 silicone mold and rigid support jacket are completed piece by piece up the entire figure.

The Rebound® 25 silicone mold and rigid support jacket are completed piece by piece up the entire figure. More mold sections are added piece by piece around the shoulders and neck of the sculpture.

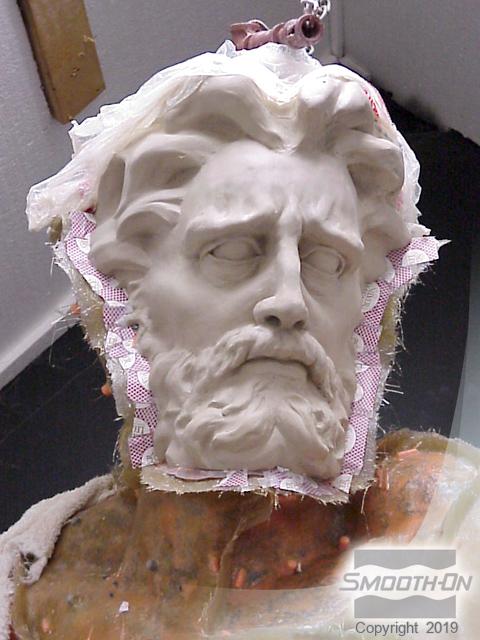

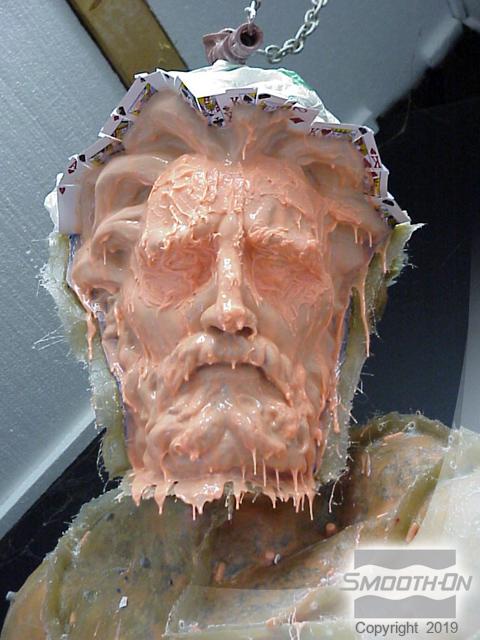

More mold sections are added piece by piece around the shoulders and neck of the sculpture. Eventually the work reaches the face of the sculpture. Volz creates a shim with pieces of playing cards. The shim separates two sections of a support shell.

Eventually the work reaches the face of the sculpture. Volz creates a shim with pieces of playing cards. The shim separates two sections of a support shell. The first layer of Rebound® 25 is applied in a thin section.

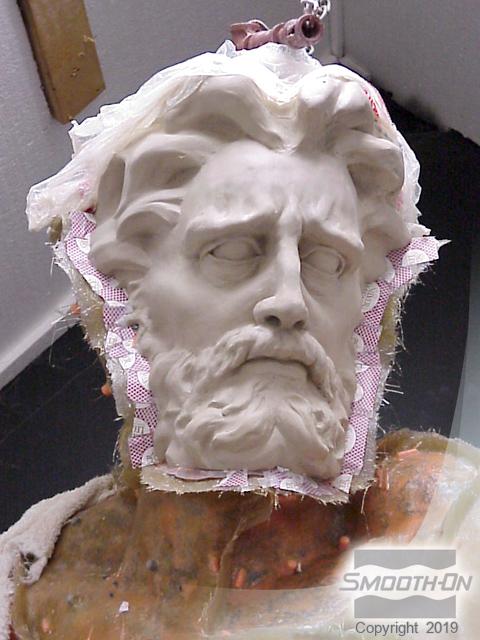

The first layer of Rebound® 25 is applied in a thin section. Rebound® 25 will pick up perfect detail from the original model. It is also soft and flexible, making it suitable for projects with significant depressions or undercuts.

Rebound® 25 will pick up perfect detail from the original model. It is also soft and flexible, making it suitable for projects with significant depressions or undercuts. A second layer of Rebound® 25 is applied after the first has partially set.

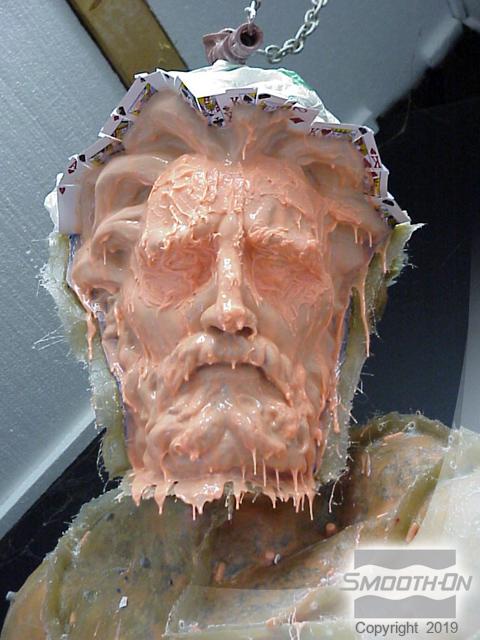

A second layer of Rebound® 25 is applied after the first has partially set. More thickened Rebound® 25 is applied to the face of the model.

More thickened Rebound® 25 is applied to the face of the model. The Rebound® 25 is allowed to fully cure.

The Rebound® 25 is allowed to fully cure. The second half of the support jacket is applied over the Rebound® 25.

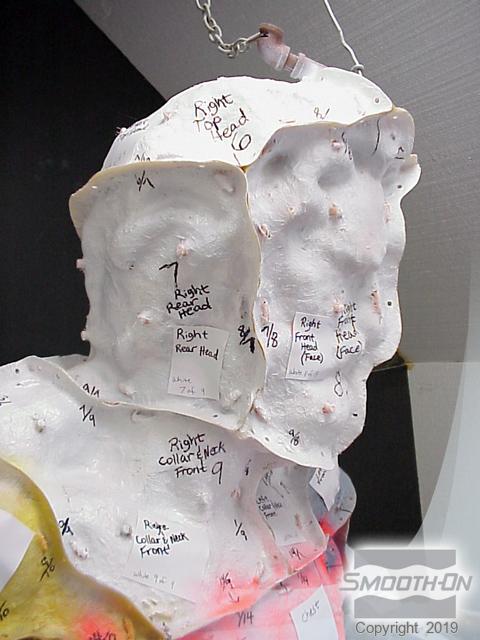

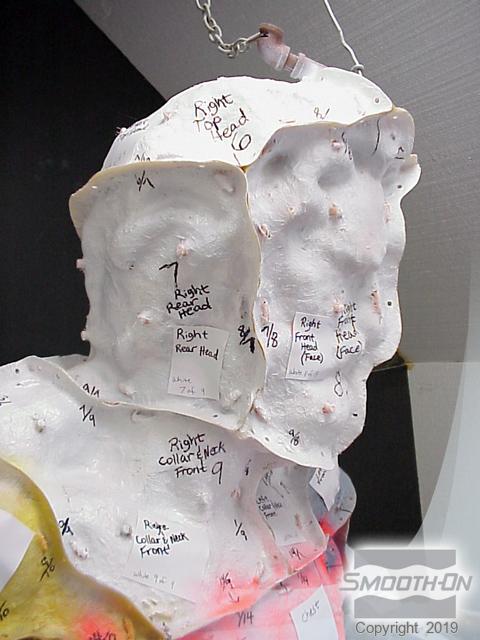

The second half of the support jacket is applied over the Rebound® 25. Volz color codes different sections of the support jacket to make re-assembly easier.

Volz color codes different sections of the support jacket to make re-assembly easier. Volz color codes different sections of the support jacket to make re-assembly easier.

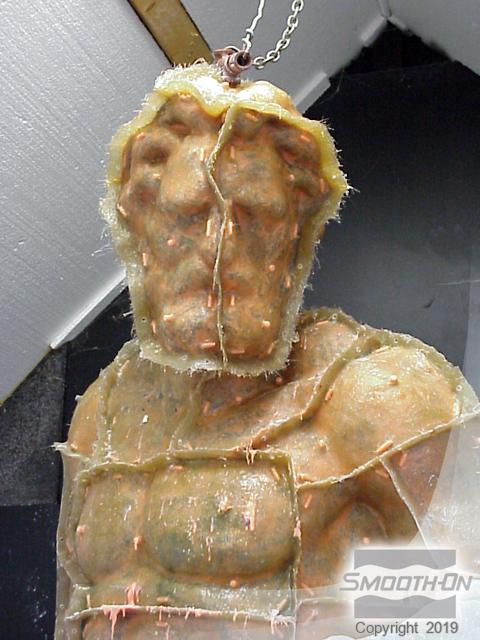

Volz color codes different sections of the support jacket to make re-assembly easier. The completed shell: Once the entire mold and support jacket have fully cured, the original can be removed.

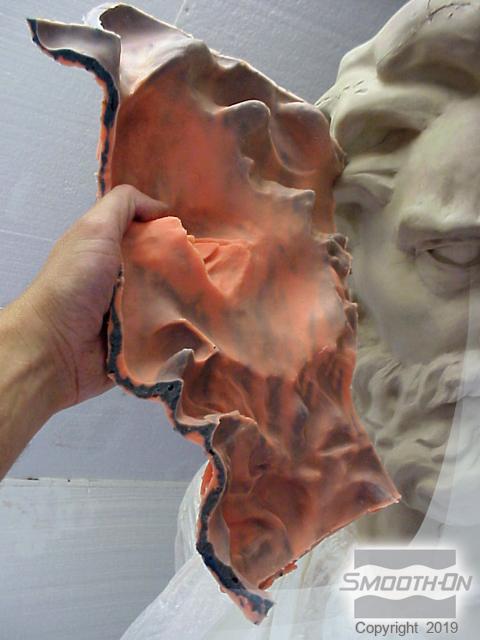

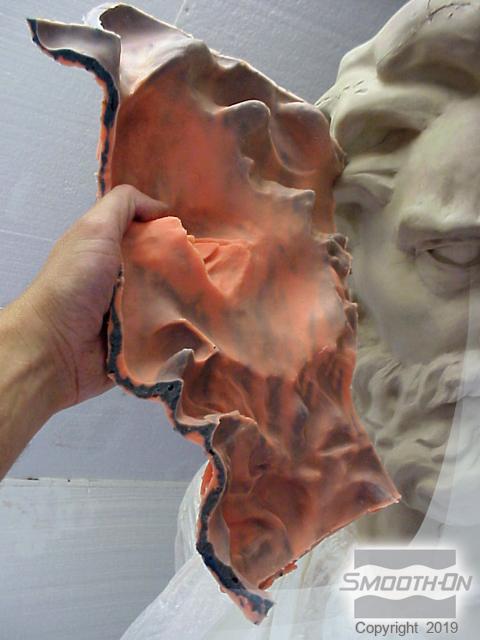

The completed shell: Once the entire mold and support jacket have fully cured, the original can be removed. With the support jacket removed, the Rebound® 25 silicone mold can be peeled away from the original model.

With the support jacket removed, the Rebound® 25 silicone mold can be peeled away from the original model. Rebound® 25 silicone rubber perfectly reproduces even the smallest detail of any original model.

Rebound® 25 silicone rubber perfectly reproduces even the smallest detail of any original model. Mold sections are re-assembled in preparation for casting. Rebound® 25 molds can be cast into many times with many different casting media.

Mold sections are re-assembled in preparation for casting. Rebound® 25 molds can be cast into many times with many different casting media.