The Scarab Club is one of Michigan’s finest venues for art, music and literature. From art exhibitions to musical performances, to poetry readings and workshops, the Scarab Club has hosted these and more. There is an unbridled energy that exists within the walls of the Scarab Club. Maybe it’s because the founders nearly 100 years ago selected the Scarab, an Egyptian symbol for rebirth, as the moniker to represent the boundless creative spirit.

When artist Karl Denton was chosen to create a commemorative plaque for the 1928 Scarab Club costume ball, he had a very unique design in mind. Using the front of the club as inspiration, Karl created a plaque using a combination of cast metal and resin. Sorta Clear 18 silicone was chosen as the mold material. The platinum cure Sorta Clear silicone can withstand the high heat of pewter casting and the chemical abrasion of fast setting Smooth Cast resins.

As this was a very limited edition (only 8 were made) the mold was destroyed as part of the process.

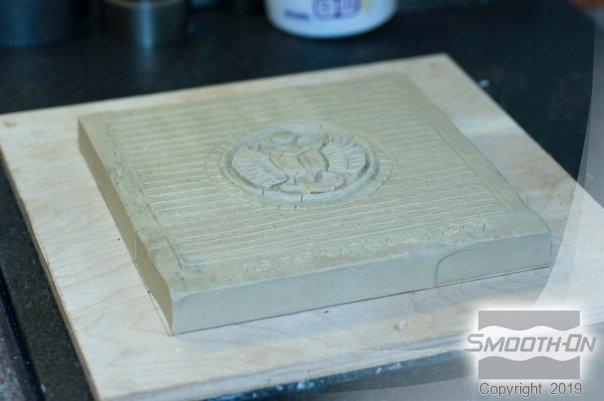

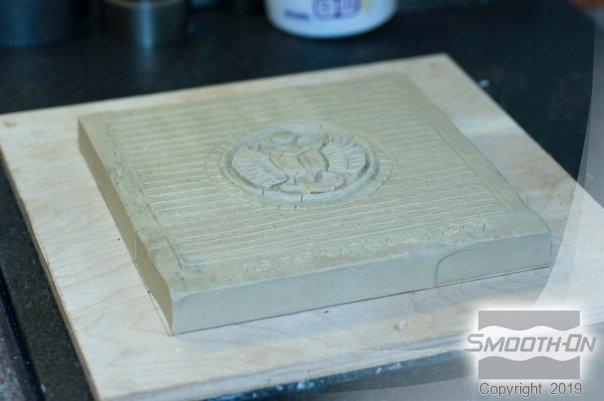

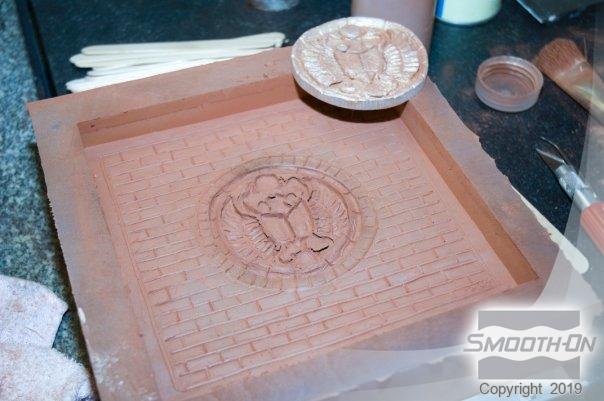

The original clay sculpture

The original clay sculpture Closeup of the detail of the sculpt

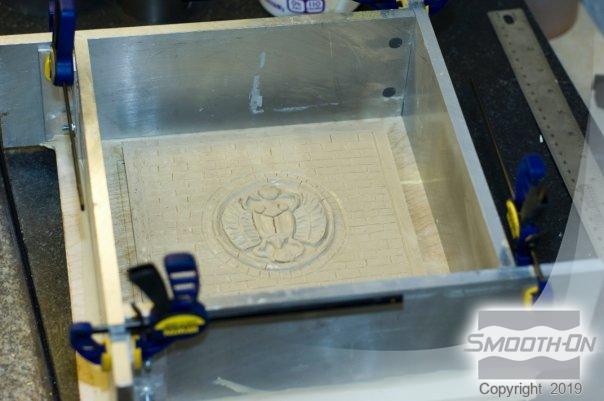

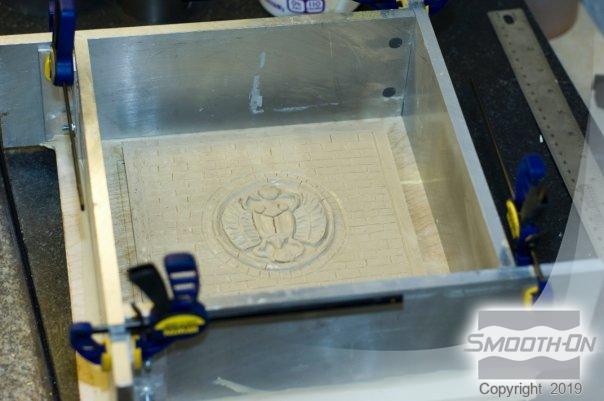

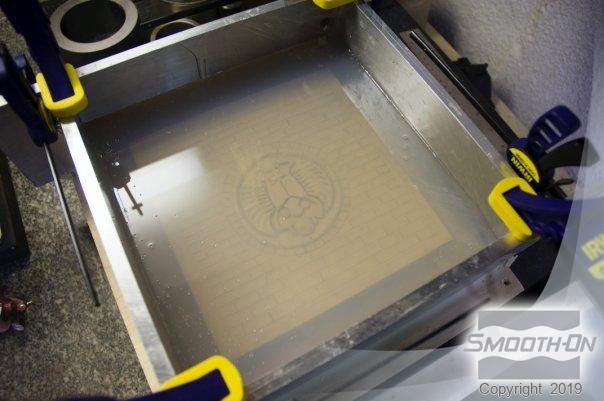

Closeup of the detail of the sculpt The original is placed in a metal mold box

The original is placed in a metal mold box Sorta Clear 18 silicone is vacuumed after measuring and mixing

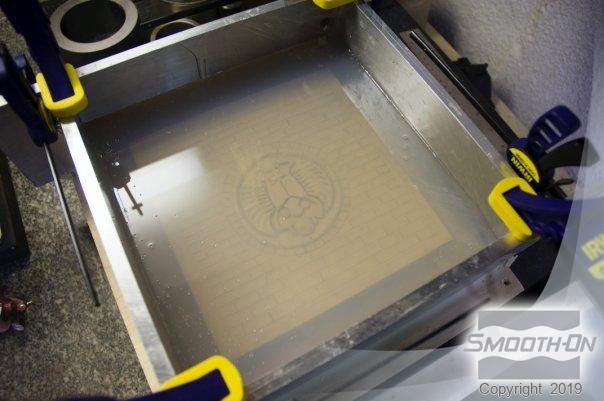

Sorta Clear 18 silicone is vacuumed after measuring and mixing The Sorta Clear rubber is slowly poured over the original model

The Sorta Clear rubber is slowly poured over the original model The original is visible through the Sorta Clear rubber

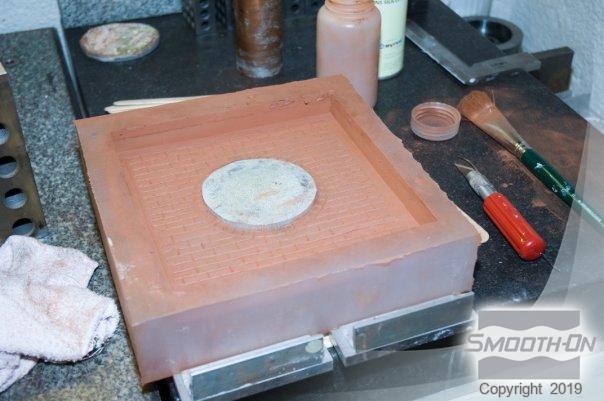

The original is visible through the Sorta Clear rubber After the original is demolded, pewter is melted and poured in the center of the mold.

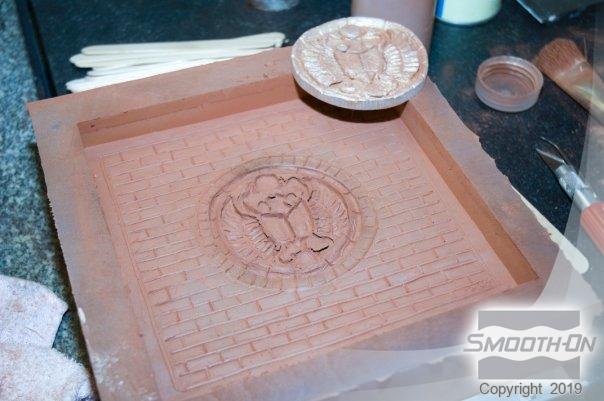

After the original is demolded, pewter is melted and poured in the center of the mold. Multiple pewter inserts are poured, demolded, and left to cool.

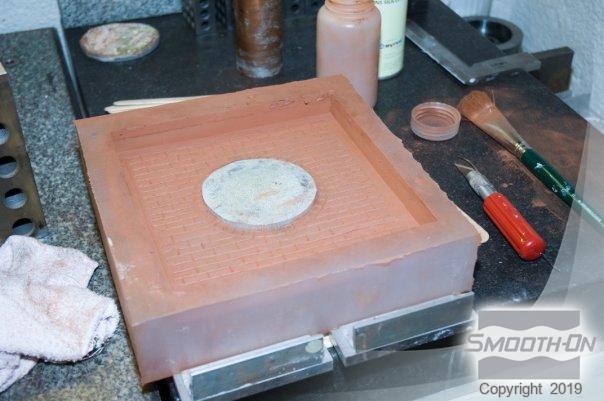

Multiple pewter inserts are poured, demolded, and left to cool. The mold is powder coated for color, and the pewter insert is prepared.

The mold is powder coated for color, and the pewter insert is prepared. The pewter insert is placed in the mold.

The pewter insert is placed in the mold. A weight holds the insert in place.

A weight holds the insert in place. Smooth Cast resin is poured into the mold.

Smooth Cast resin is poured into the mold. The Smooth Cast cures in 15 minutes.

The Smooth Cast cures in 15 minutes. Once the resin is cured the weight is removed.

Once the resin is cured the weight is removed. A small amount of Smooth Cast resin is poured into the center of the mold where the weight was.

A small amount of Smooth Cast resin is poured into the center of the mold where the weight was. Once the resin cures, the small void is undetectable.

Once the resin cures, the small void is undetectable. The mold is destroyed. This drastic measure ensures a ''limited edition'' run of castings.

The mold is destroyed. This drastic measure ensures a ''limited edition'' run of castings. Multiple castings are made in this fashion.

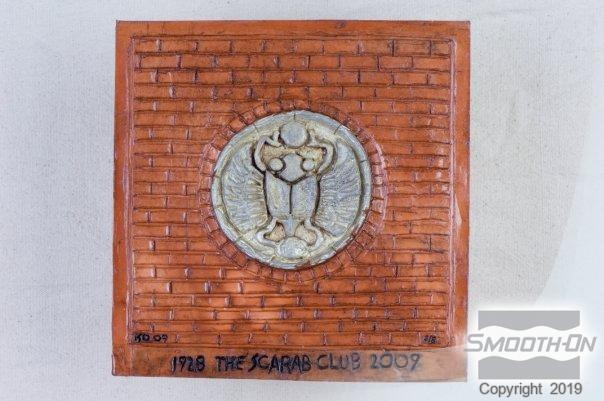

Multiple castings are made in this fashion. The details in the castings are painted.

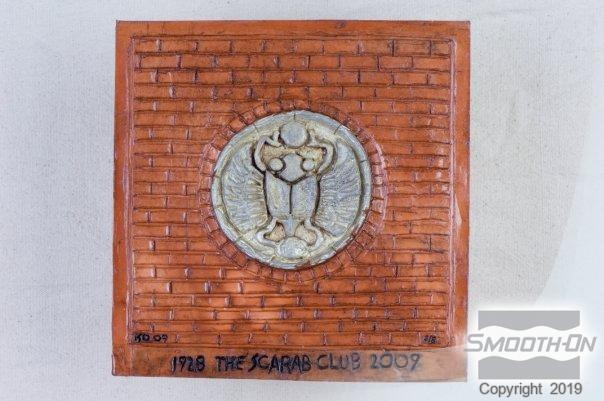

The details in the castings are painted. The finished plaques is ready for the ceremony.

The finished plaques is ready for the ceremony.