Bill Klopping (Beyond Design, Walton, NY) was challenged to create a world class display that would be viewed by millions of visitors at New York City’s Christmas Wonderland.

Fabricating the finished elements for a complex project like this would call for employing ingenious mold making and casting techniques. Bill’s choice of materials: Mold Max® 20 silicone rubber for making the molds and Crystal Clear® plastic to make the castings.

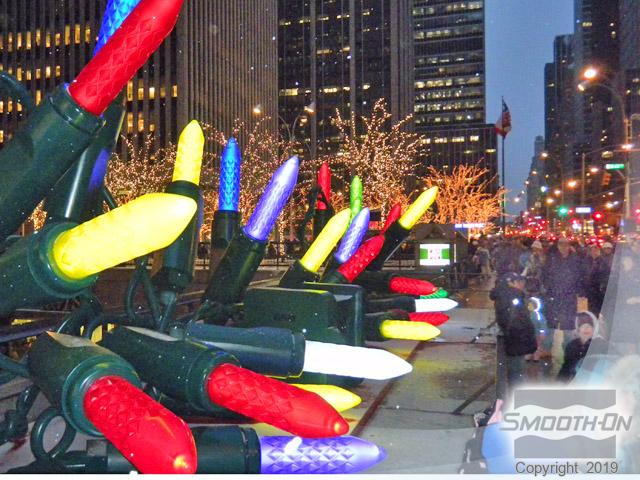

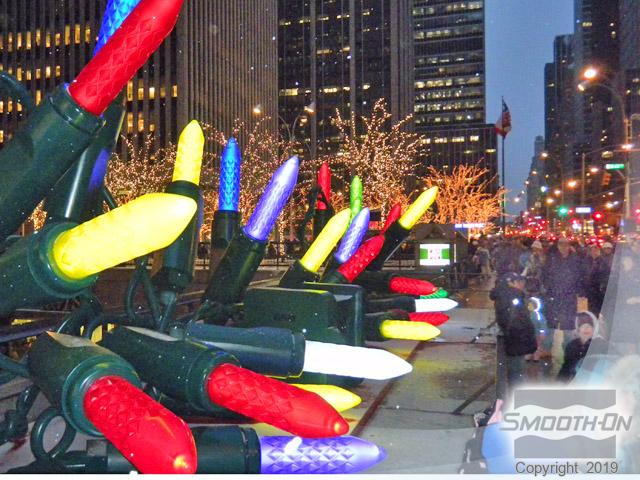

Under a blanket of newly fallen snow, a super-sized Christmas lights display is enjoyed by New Yorkers celebrating the holiday season as they pass the world famous Radio City Music Hall.

Under a blanket of newly fallen snow, a super-sized Christmas lights display is enjoyed by New Yorkers celebrating the holiday season as they pass the world famous Radio City Music Hall. A rigid core of PVC piping with a cast cone top will support two separate silicone rubber molds during the casting process.

A rigid core of PVC piping with a cast cone top will support two separate silicone rubber molds during the casting process. Mold Max® 20 rubber inner and outer molds were made of a sculpted original to perfectly capture the shape, dimension and waffle pattern of the individual light bulbs.

Mold Max® 20 rubber inner and outer molds were made of a sculpted original to perfectly capture the shape, dimension and waffle pattern of the individual light bulbs. The outer rubber mold is pulled over the inner rubber mold.

The outer rubber mold is pulled over the inner rubber mold. This will create a ''gap'' or cavity that will be filled with Crystal Clear® resin.

This will create a ''gap'' or cavity that will be filled with Crystal Clear® resin. The rigid support shell or mother mold is fitted and secured over the outer rubber mold.

The rigid support shell or mother mold is fitted and secured over the outer rubber mold. Crystal Clear® resin is measured, color pigmented and mixed thoroughly.

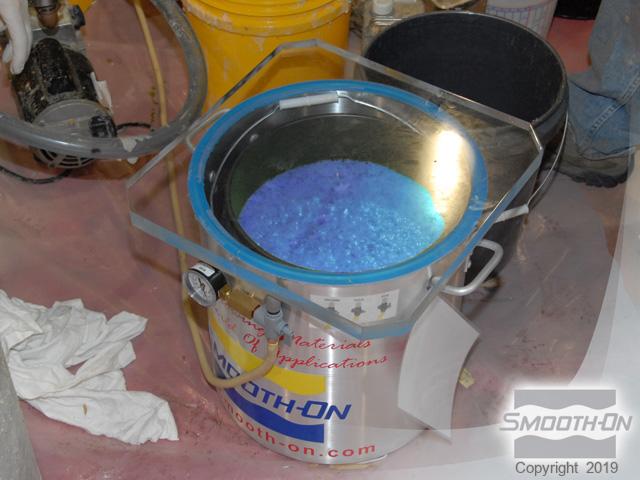

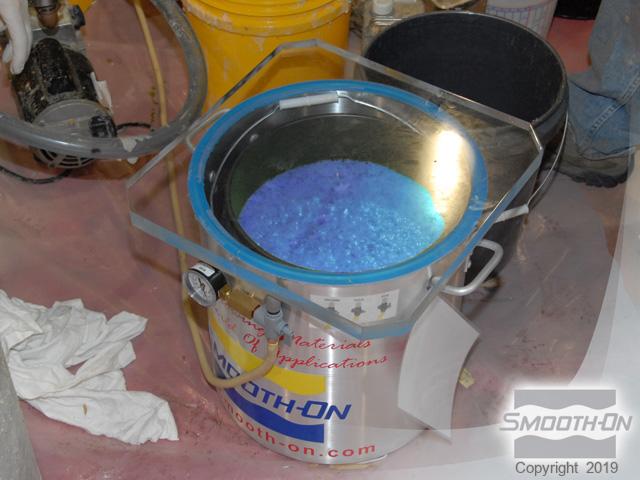

Crystal Clear® resin is measured, color pigmented and mixed thoroughly. The mixed resin is then de-aired in a vacuum chamber.

The mixed resin is then de-aired in a vacuum chamber. The color pigmented Crystal Clear® resin is pressure dispensed into the bottom of the mold structure using a pressure pot. The resin is allowed to rise slowly to fill the gap between the rubber mold and the support shell.

The color pigmented Crystal Clear® resin is pressure dispensed into the bottom of the mold structure using a pressure pot. The resin is allowed to rise slowly to fill the gap between the rubber mold and the support shell. Once filled, the mold structure is placed in a hot box and heat cured.

Once filled, the mold structure is placed in a hot box and heat cured. Following the full cure cycle, the resin casting is ready to be demolded.

Following the full cure cycle, the resin casting is ready to be demolded. A special hoist was constructed to remove the outer rubber mold from the cured Crystal Clear® plastic.

A special hoist was constructed to remove the outer rubber mold from the cured Crystal Clear® plastic. Bill Klopping standing next to one of his Christmas Light creations while artisans assemble the structure in the background.

Bill Klopping standing next to one of his Christmas Light creations while artisans assemble the structure in the background. test assembled

test assembled Another view of the project as it is staged prior to being shipped to New York City

Another view of the project as it is staged prior to being shipped to New York City At night the brilliantly colored lights ignite the entire block.

At night the brilliantly colored lights ignite the entire block. Passersby marvel at the Crystal Clear® resin display, enjoying all that New York City has to offer at Christmas Time.

Passersby marvel at the Crystal Clear® resin display, enjoying all that New York City has to offer at Christmas Time.