How To Make a 1 Piece Silicone Cut Mold

Overview

Mold Star® 15 is perfect for experienced mold makers or people just starting out. It is an easy to use silicone rubber that offers performance other mold making rubbers do not:

- Easy To Use – the mix ratio is 1A:1B by volume… no weighing scale necessary.

- No Vacuum Degassing Necessary – Unlike other platinum silicones, Mold Star® de-airs itself resulting in bubble-free molds.

- Long Working Time – Pot life is 50 minutes at room temperature, offering time to make molds of large models.

- High tear strength and other great performance properties.

- Minimal long term shrinkage.

- Very long library life of many years.

Fully cured rubber can be used to cast low-temperature melt metal alloys, urethane, epoxy or polyester resins, wax, plasters or concrete.

Important: Mold Star® 15 cannot be used with modeling clays containing sulfur. Even if the model is sealed.

Materials Used in this Tutorial

- Mold Star 15

- Smooth-Cast ONYX

- SuperSeal

- Hot Glue

- Ease Release 200

- Mold Strap

- Paint Brush

- Mixing Containers

- Mixing Sticks

Step 1: Preparing Model for Molding

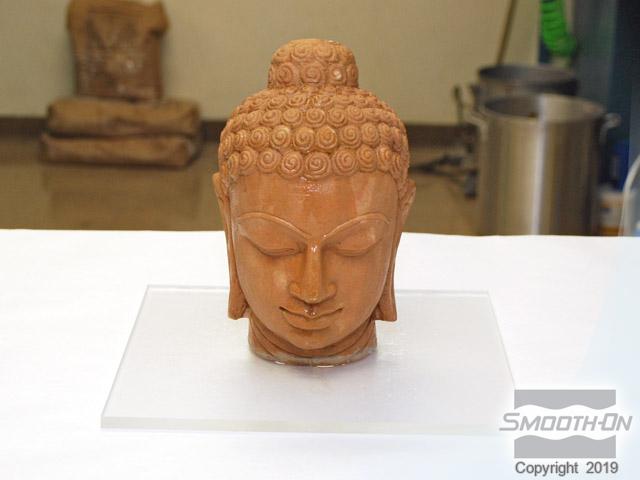

Mold Star® 15 is a Shore 15A platinum silicone that is mixed 1A:1B by volume, with no weighing scale necessary. The original model is a stone sculpture that should be prepared prior to applying mold rubber.

Hot glue is used to secure the model to the base of the mold box. The model is pressed firmly to the base of the mold box and the hot glue is allowed to dry fully. The original model is made of stone and is porous. It should first be sealed prior to applying mold rubber. SuperSeal® is a low-viscosity sealing agent that can be brushed onto the surface without affecting detail. SuperSeal® is applied to the original stone model.

Depending on the porosity of the original model, multiple coats of SuperSeal® may be necessary. Once SuperSeal® has been applied to the entire model, it is allowed to dry for 5 minutes. Optional: Ease Release® 200 is applied over the original model to aid in demolding.

The four walls of the mold box are assembled around the model. They are held in place by a mold strap until hot glue can be applied to all seams. Hot glue is applied to all seams of the mold box. It is important that the box is completely airtight to prevent any leaks. With the model prepped and the mold box fully assembled, Mold Star® 15 can now be poured over the model.

Step 2: Dispensing Mixing and Applying Mold Star™ 15

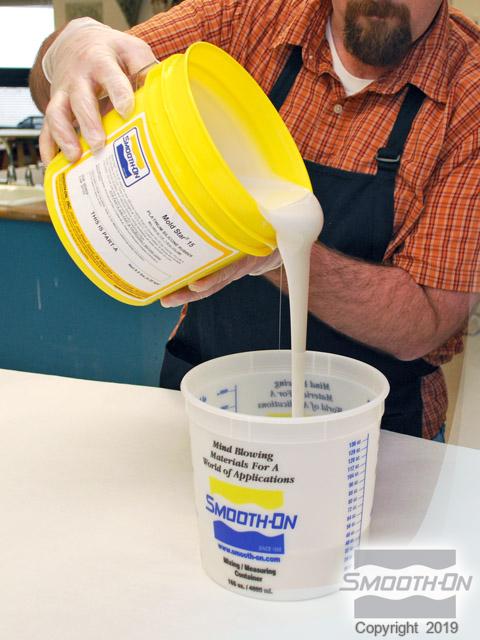

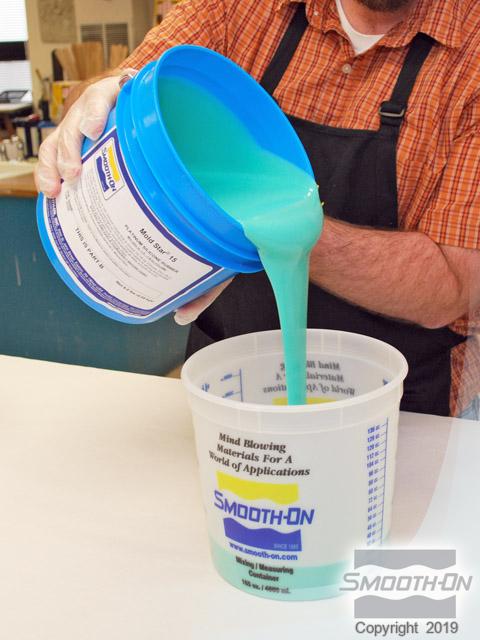

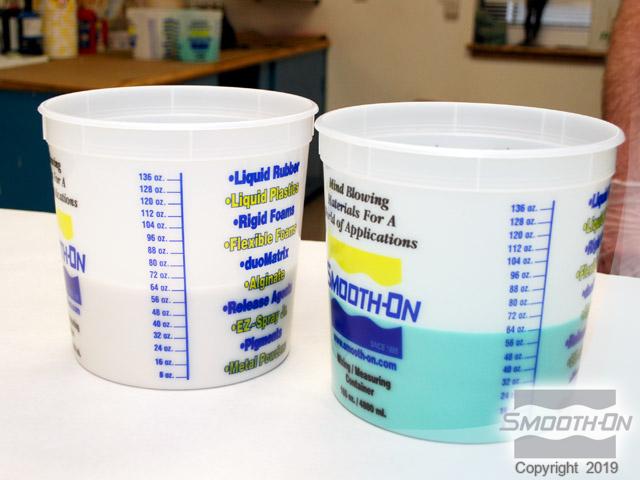

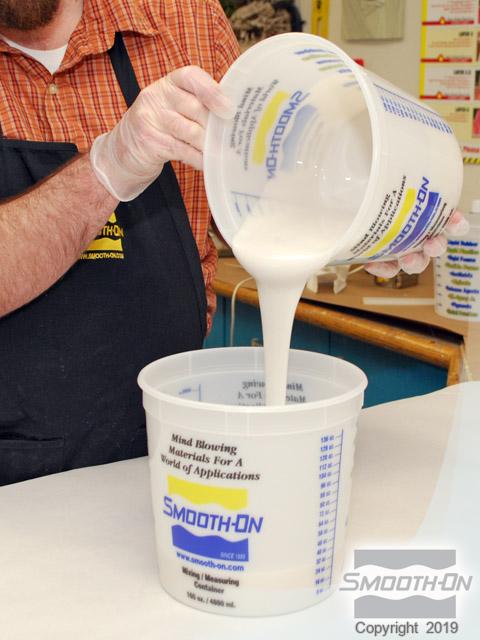

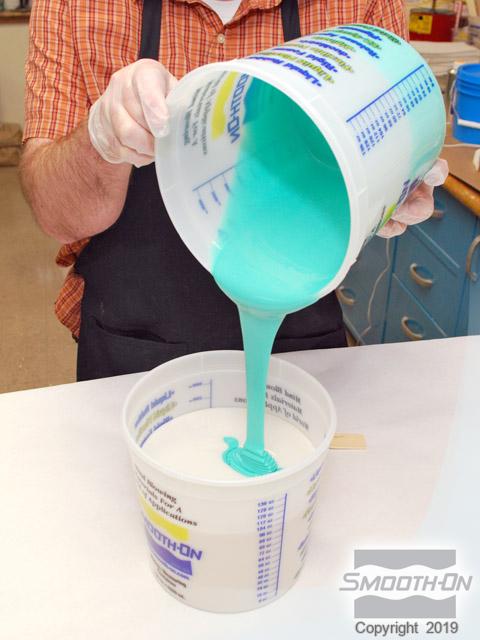

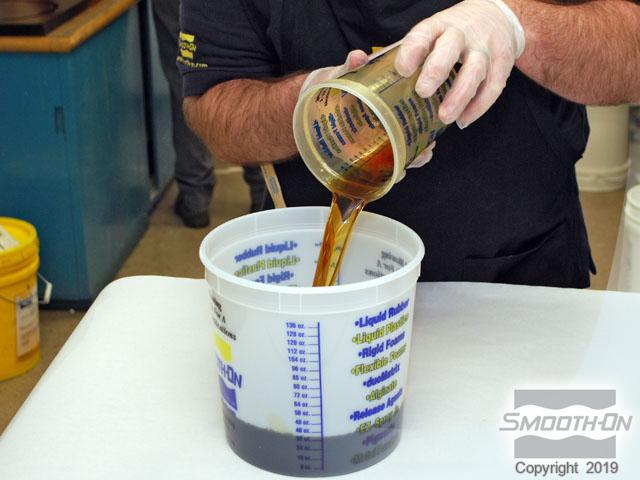

A partial gallon kit of Mold Star™ 15 will be used for the mold. Part A is dispensed into a measuring bucket. An equal amount of Part B is dispensed into a separate measuring bucket. With equal amounts of Parts A and B dispensed, the Mold Star™ 15 can now be combined. Part A is dispensed into a mixing bucket. Part B is added to the mixing bucket with the Part A.

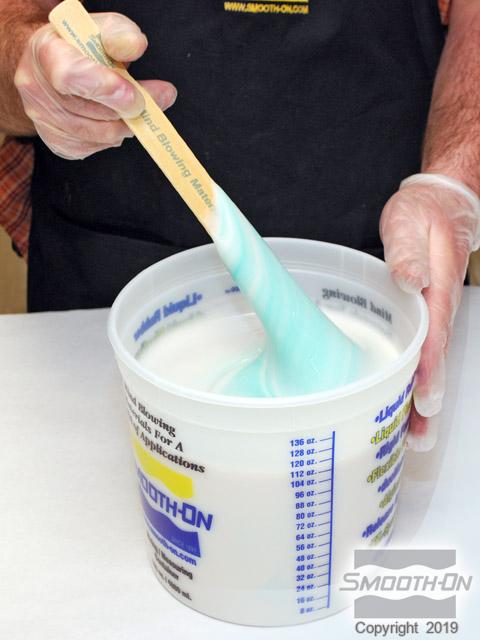

The two components are mixed by hand. Care is also taken to scrape the sides and bottom of the mixing container. As the two components are mixed, the colors of Part A (white) and Part B (green) will combine to a solid light green. To ensure a thorough mixture, the contents are transferred into a second, clean mixing bucket.

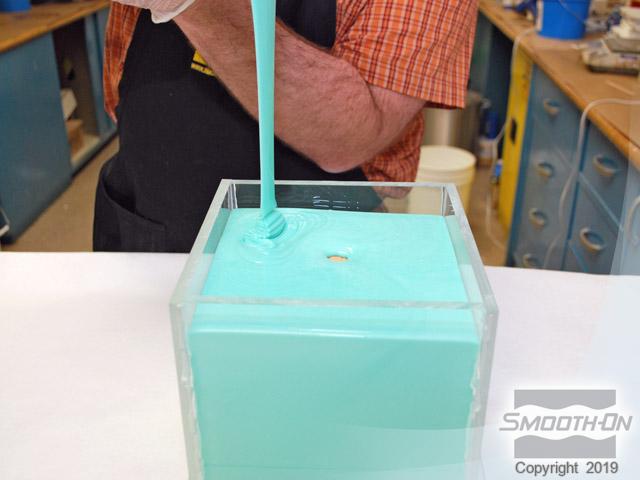

The two components are mixed until the color is uniform with no white or green streaks present. Because Mold Star™ 15 is low viscosity compared to other platinum silicones, vacuum degassing is not necessary. The mixture is poured slowly in the corner of the mold box. The material is allowed to seek its own level over the model. This helps eliminate the potential for entrapped air.

Mold Star™ 15 has a long (45 minute) working time. Not only does this help eliminate bubble entrapment, it also allows the material to be poured slowly or over a large area. Once poured, allow Mold Star™ 15 to cure for 4 hours before demolding.

Step 3: Demolding Original Model from Mold

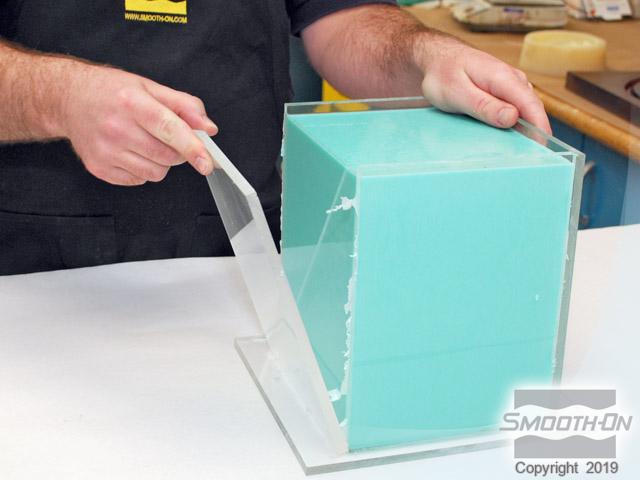

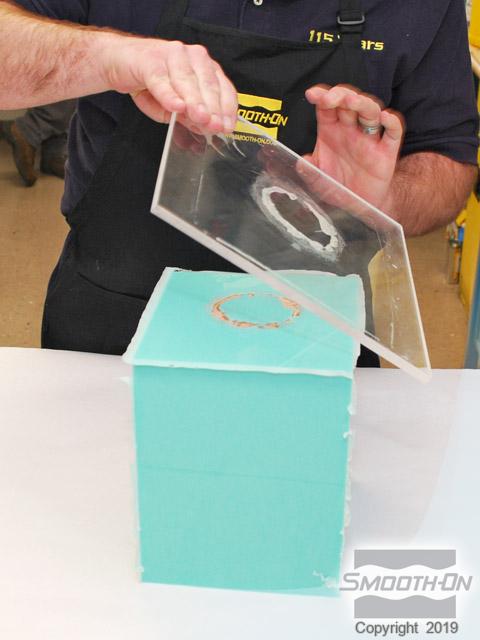

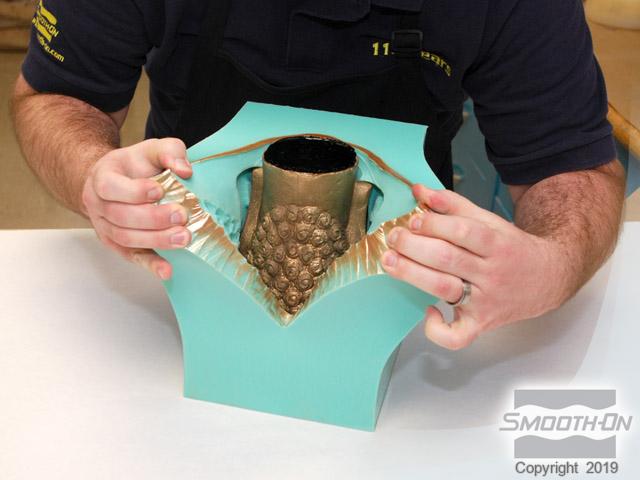

Once Mold Star® 15 has cured for 4 hours, the mold box can carefully be disassembled. The mold is flipped upside down and the bottom of the mold box is removed. Flashing is trimmed from the edges of the mold and the opening of the mold cavity. To remove the original model, a seam is cut down the back of the mold.

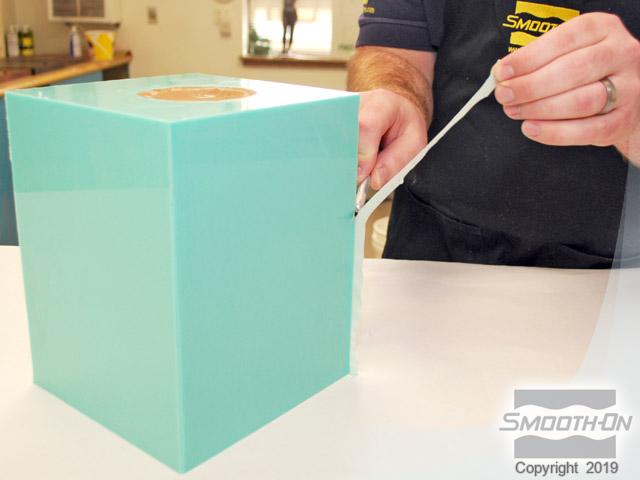

Mold Star® 15 has great tear strength, allowing the mold to be stretched a great deal without tearing. The seam is cut down the back of the mold until the original piece can be easily removed. The original model is removed from the mold. The Mold Star® rubber captured perfect detail from the original model.

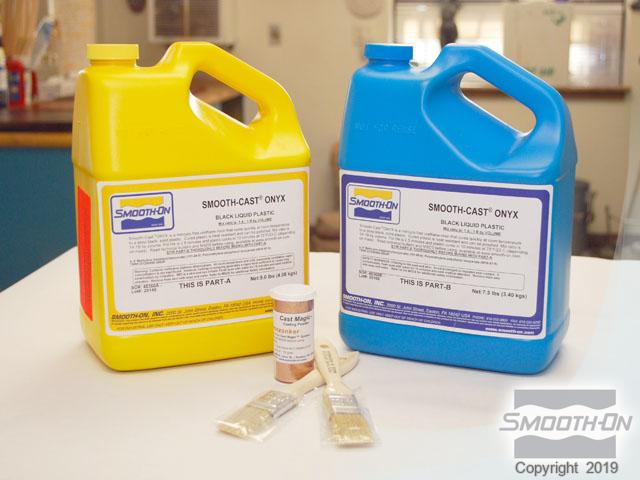

Step 4: Casting A Replica With Smooth Cast® ONYX™

First, Smooth-Cast® ONYX™ will be poured into the mold. For a metallic effect, Cast Magic® Bronzonker powder will be applied to the mold surface first by a brush. Once the Bronzonker is applied to the entire surface, any excess is blown off with compressed air. A mold strap is used to keep the mold tightly closed while casting resin.

Part A of Smooth-Cast® ONYX™ is shaken prior to dispensing. Part B of Smooth-Cast® ONYX™ is shaken prior to dispensing. Part A is dispensed into a measuring cup. An equal amount of Part B is dispensed into a separate measuring cup. Smooth-Cast® ONYX™ is mixed 1A:1B by volume. Next, Part A is added to a mixing bucket and Part B is added to the same mixing bucket. Parts A and B are mixed thoroughly. Care is taken to scrape the sides and bottom of the mixing bucket.

The Smooth-Cast® ONYX™ is poured into the mold.

Step 5: Demolding & Finishing Piece

Smooth-Cast® ONYX is allowed to cure for 15 minutes prior to demolding. The casting is demolded. The Cast Magic® Bronzonker transfers to the casting surface, producing an inexpensive metallic effect.

The last photo below, shows the original stone model (left) with the Mold Star® 15 mold (center) and the Smooth-Cast® ONYX casting (right). A perfect copy!