How To Use PC‑3™ To Install a Lab Countertop

Overview

Smooth-On PC-3™ Laboratory Table Top Cement is a two-component, black epoxy resin compound designed to join, bond and caulk sections of laboratory counters and tables.

This epoxy resin cement is heavily filled and will adhere to vertical surfaces without sagging. It cures at room temperature with extremely low shrinkage. PC-3™ contains no volatile organic compounds (VOC’s) or solvents. It ischemically stable and bonds strongly to natural and artificial stones, most metals, glass, wood and to thermosetting resins such as polyester, phenolic and epoxy.

In this step by step, an epoxy resin countertop is adhered to a newly installed lab counter.

Materials Used in this Tutorial

- PC-3

- Mixing Containers

- Mixing Sticks

- Cardboard

- Putty Knife

- Clamps

- Cloth

Step 1: Dispensing and Mixing PC-3

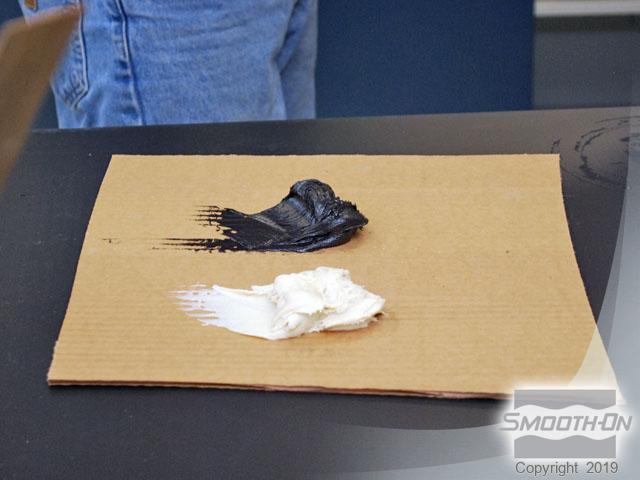

PC-3 is a 1:1 mix ratio material, making it very easy to measure out. Begin by dispensing equal amounts of Part A (black) and Part B (tan) paste onto a scrap piece of cardboard. Mix the paste components using a metal putty knife until a uniform color is reached, the PC-3 is ready to use.

Step 2: Applying PC-3

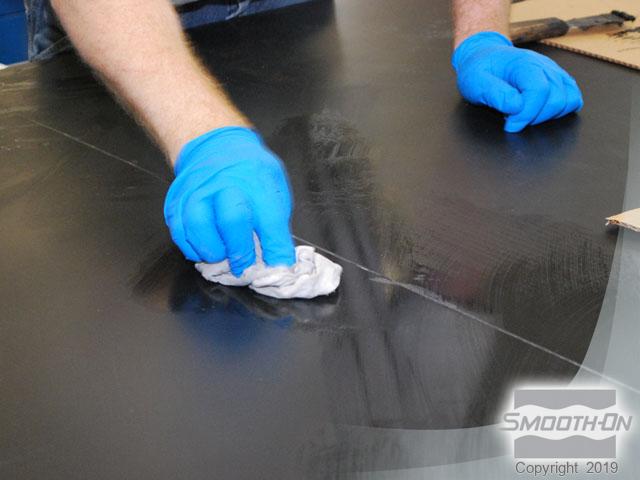

Next, apply PC-3 epoxy to the seams between the two adjoining sections of countertop. Press the sections together and excess epoxy material should rise from the seam. Use clamps to hold the countertop sections together and a putty knife to spread out and remove excess PC-3. Use a dampened cloth to further clean uncured material from the seams.

To apply a backsplash section, mix and apply a small amount of PC-3 to the joint and wall surface, then press the backsplash section into place. Use a putty knife to spread the PC-3.

Step 3: Finishing

To finish cleaning the seams, use a dampened cloth. PC-3 does an excellent job of joining complicated seams. Allow to cure overnight in order for it to reach high strength before use. The high tensile strength of PC-3 allows it to be used in many different lab top configurations. Its ease of use and extremely high strength have made PC-3 the industry standard for lab top installation.