How To Mold a Face With Alja‑Safe™ Acrobat™

Overview

Alja-Safe™ Acrobat™ is a fiber reinforced "non-sag" version of original Alja-Safe™ life casting alginate. Acrobat is thicker and holds vertical surfaces allowing the user better control for making molds of the face, torso, etc. Alja-Safe™ Acrobat™ reproduces perfect detail from all body surfaces and is good for making temporary molds that can be used to make highly detailed reproductions cast in wax, plaster, Matrix™ NEO™ (polymer modified gypsum), platinum cure silicone or Smooth-Cast™ 300Q ultra-fast urethane resin.

Easy To Use - Mix ratio is 1 part Alja-Safe™ Acrobat™ powder sifted into 1 part water (1:1 by volume). Working time is 5 minutes and cure time is 8 minutes, assuming a water temperature of 80° F / 27° C.

Like original Alja-Safe™ - Alja-Safe™ Acrobat™ is skin safe and does not contain crystalline silica (a known carcinogen).

Materials Used in this Tutorial

- Alja-Saf™ Acrobat™

- Gypsona Plaster Bandages

- Non-Latex Plastic Bald Cap

- duoMatrix™ NEO™

- Paint Brush

- Wooden Tool

- Mixing Containers

- Mixing Sticks

Step 1: Measuring Material/Preparing Model

First, meausure out equal amounts of Alja-Safe™ Acrobat™ and water into plastic cups. Firmly pack the Alja-Safe™ Acrobat™ into the cup. Alja-Safe™ Acrobat™ has a 1:1 mix ratio by volume. Prepare the model with a non-latex plastic bald cap.

Step 2: Mixing and Applying Alja-Safe™ Acrobat™

Pour the water into a mixing container and sift the Alja-Safe™ Acrobat™ onto the water. Mix the material rapidly and thoroughly (you can also use a turbine drill mixer). The resulting material holds a vertical surface well.

Apply the Alja-Safe™ Acrobat™ to the face of the model using a wooden spatula and smooth over the surface of the face. Leave nostril holes open to provide an airway. Use a small wooden stick to further smooth out the material. After 10 minutes, the Alja-Safe™ Acrobat™ will be fully cured.

Step 3: Applying Plaster Bandages

Moisten Gypsona™ plaster bandages in warm water and place them over the cured Alja-Safe™ Acrobat™. Allow the bandage support shell to cure for 10 minutes.

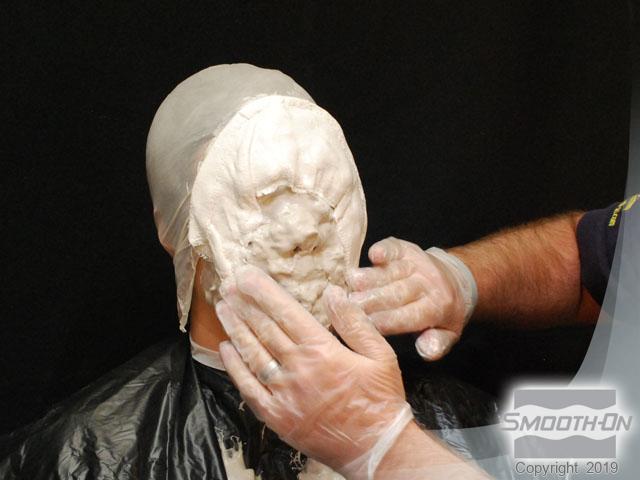

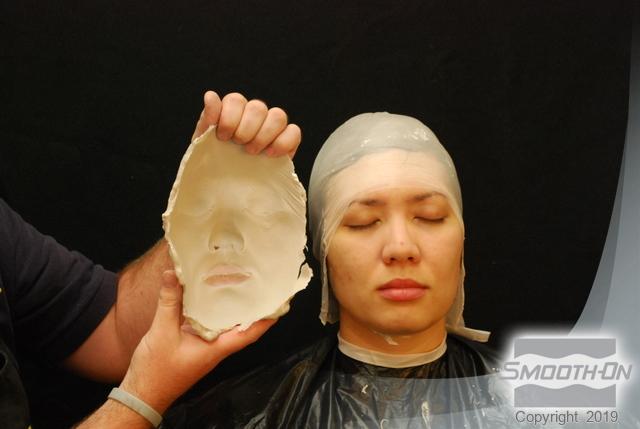

Step 4: Demold and Finishing Mold

Gently remove the bandage suport shell and peel the Alja-Safe™ Acrobat™ away. The fiber reinforcement of Alja-Safe™ Acrobat™ reduces the risk of the mold tearing. Use a small amount of clay to seal the nostril holes. The Alja-Safe™ Acrobat™ captures excellent detail.

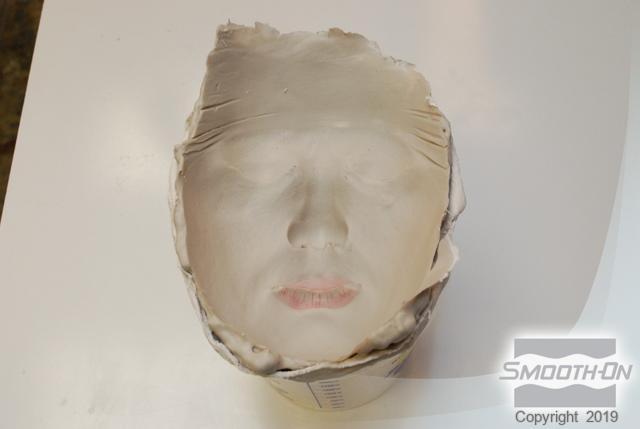

Step 5: Casting duoMatrix™ NEO™ and Finishing the Casting

duoMatrix™ NEO™ is a polymer gypsum casting material that is measured out 2A:1B by volume. Measure out and mix the material and then brush it into the mold. Add additional duoMatrix™ NEO™ to provide strength. After 60 minutes remove the bandage support shell.

Remove the Alja-Safe™ Acroba™ mold from the duoMatrix NEO™ cast. A wooden tool can be used to remove any slight defects. The duoMatrix™ NEO™ casting reflects excellent detail.