AC Worx Orthopedic, LLC of Crookston, Minnesota was recently developing a concept for an orthopedic pillow based on a design by a surgeon intended to alleviate pain for spinal cord injury patients. The unique design had been rendered using CAD software and a 3-D model was then created in EPS rigid foam. AC Worx reached out to Smooth-On for material ideas to take them to the next step in the prototyping process. Before they could make a mold of the EPS foam model, it needed to be sealed. Epsilon® brushable epoxy coating was used to seal and protect the fragile EPS model. Epsilon® is easy to measure, mix and apply. Two layers provide a durable coating that, when fully cured, is easy to paint. Epsilon® is also color neutral and easy to pigment with SO-Strong® color tints. Once the EPS was hard coated with Epsilon®, rubber molds were made with Mold Max® 25 silicone rubber. Prototype pillows were then made using FlexFoam-iT!® 6 and FlexFoam-iT!® VIII Pillow Soft flexible foams.

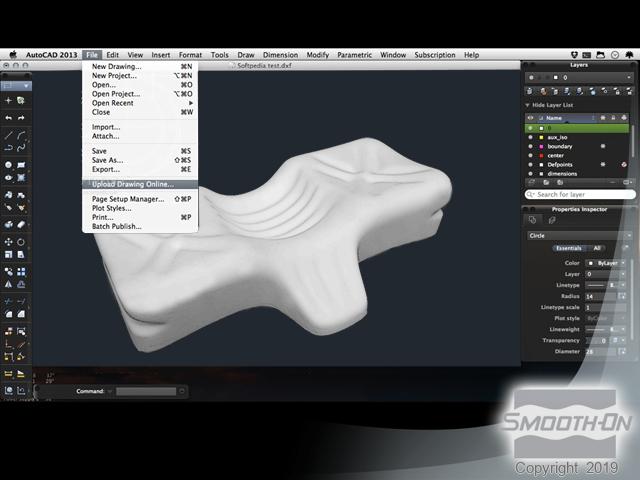

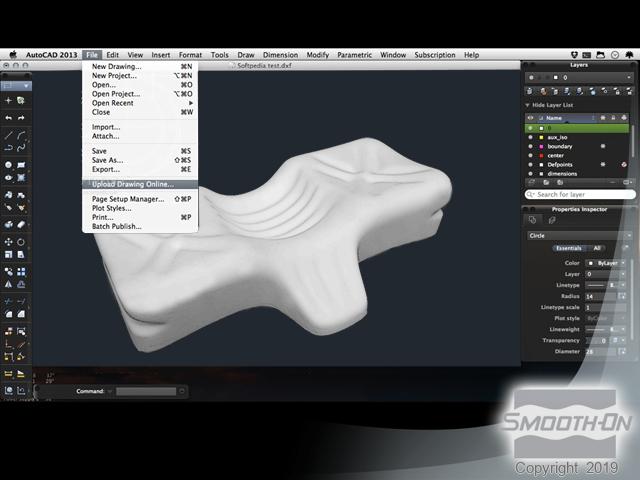

A design was made on a popular CAD program of what the finished pillow will look like.

A design was made on a popular CAD program of what the finished pillow will look like. Rigid foam model was CNC routed based on CAD program design.

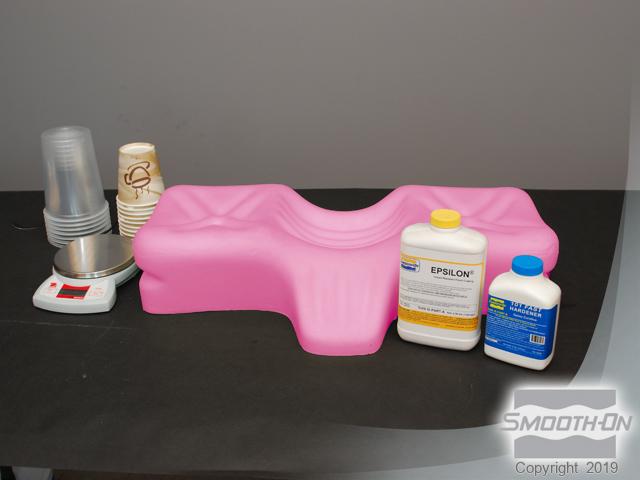

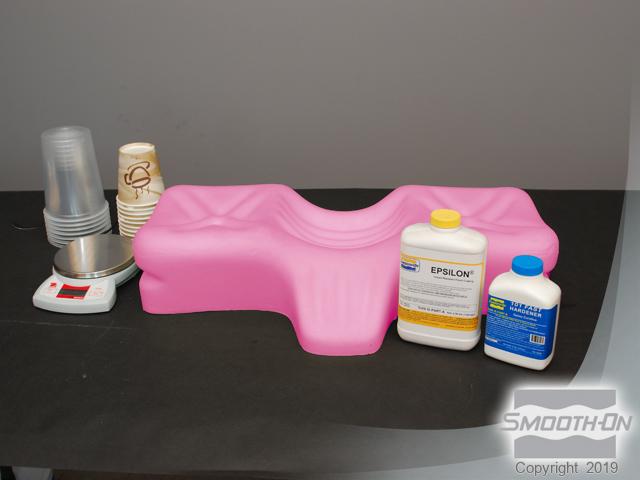

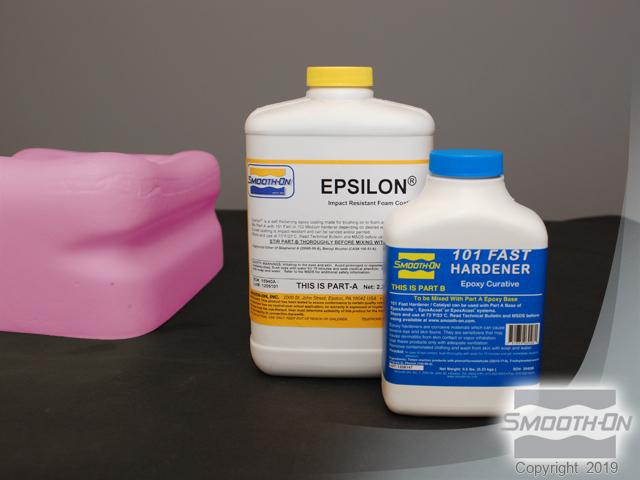

Rigid foam model was CNC routed based on CAD program design. Epsilon® EPS coating will be brushed over foam model surface to seal and make ready for making a silicone rubber mold.

Epsilon® EPS coating will be brushed over foam model surface to seal and make ready for making a silicone rubber mold. Epsilon® self thickens, is self-leveling and holds a vertical surface without sagging. Finished coating is hard, smooth and easy to paint if post finishing is required.

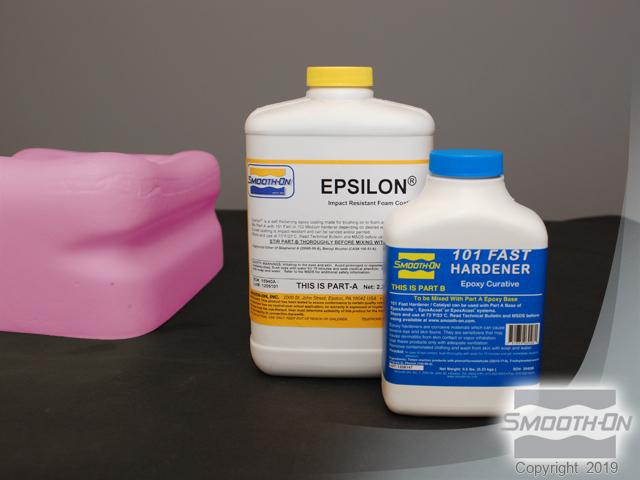

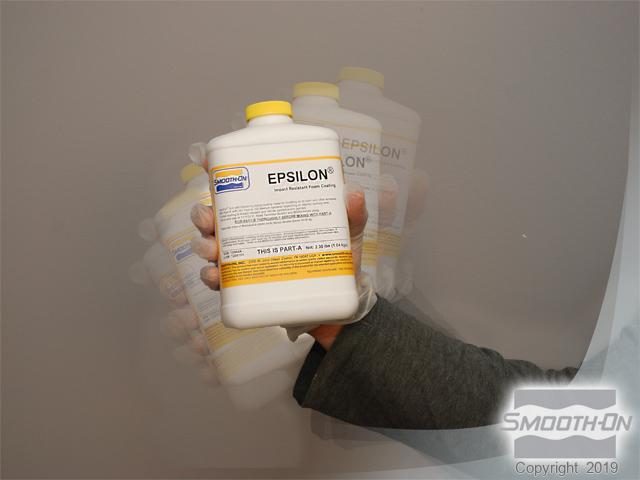

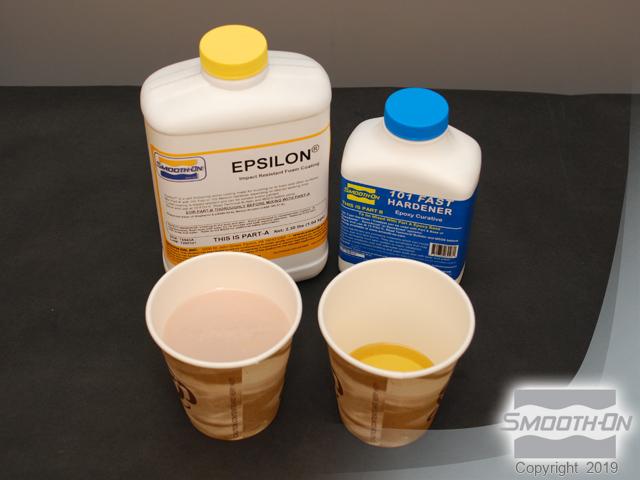

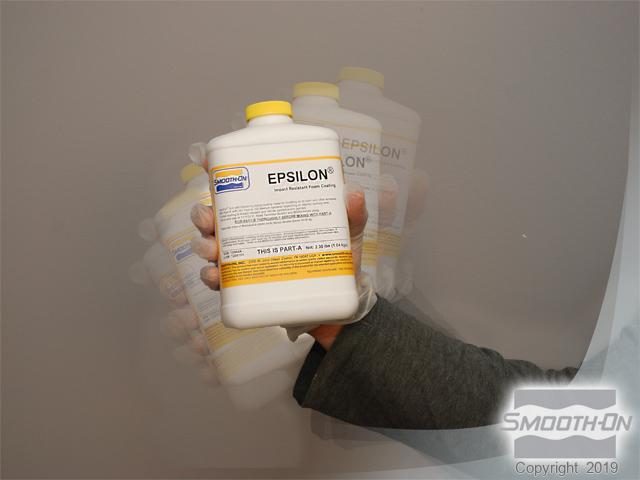

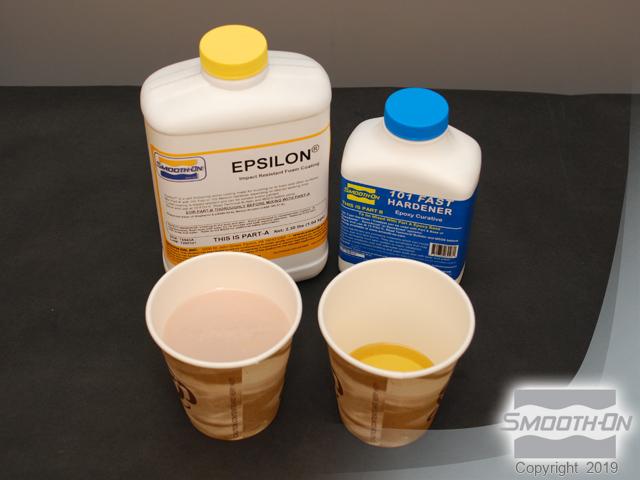

Epsilon® self thickens, is self-leveling and holds a vertical surface without sagging. Finished coating is hard, smooth and easy to paint if post finishing is required. Epsilon® Part A is pre-mixed.

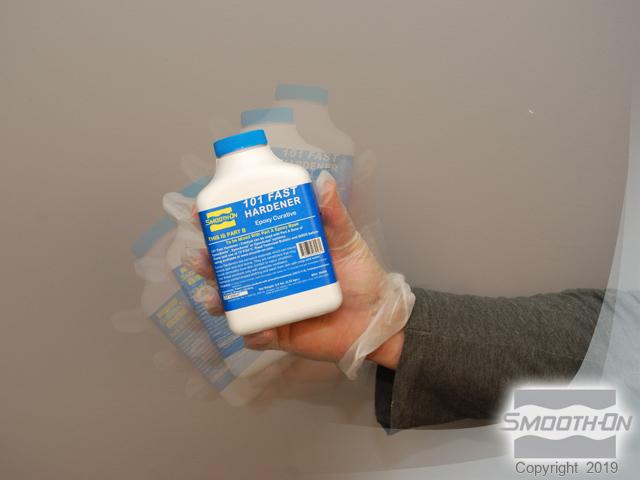

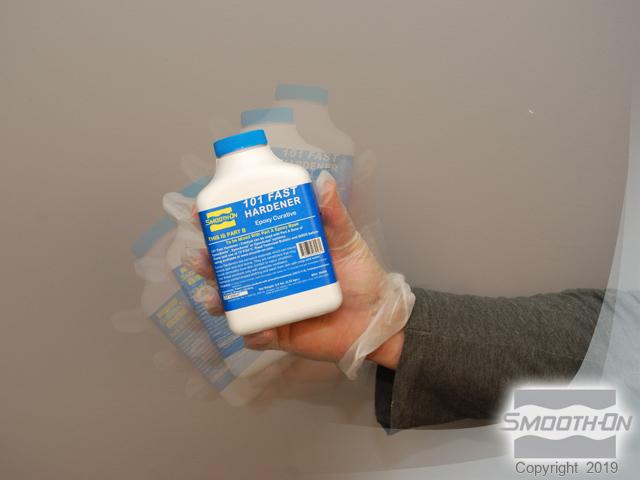

Epsilon® Part A is pre-mixed. The 101 Fast catalyst is also pre shaken prior to dispensing.

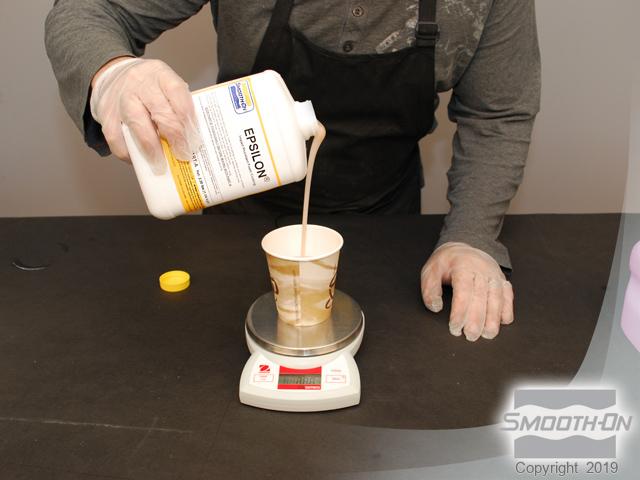

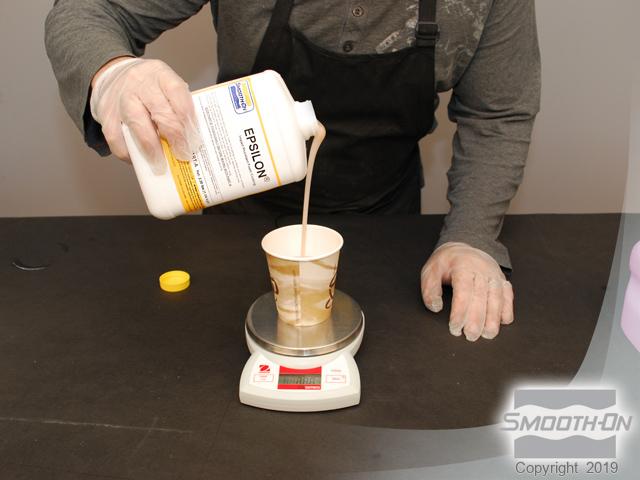

The 101 Fast catalyst is also pre shaken prior to dispensing. Mix ratio is 100A:20B by weight. An accurate gram scale is required to precisely measure.

Mix ratio is 100A:20B by weight. An accurate gram scale is required to precisely measure. Parts A and B are dispensed into a mixing container.

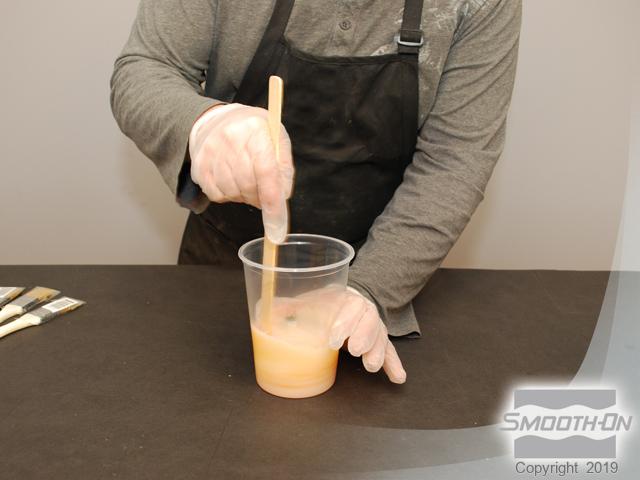

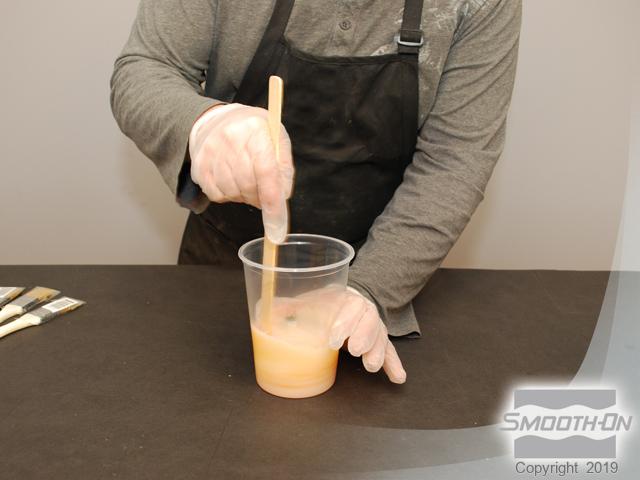

Parts A and B are dispensed into a mixing container. Careful mixing technique is employed.

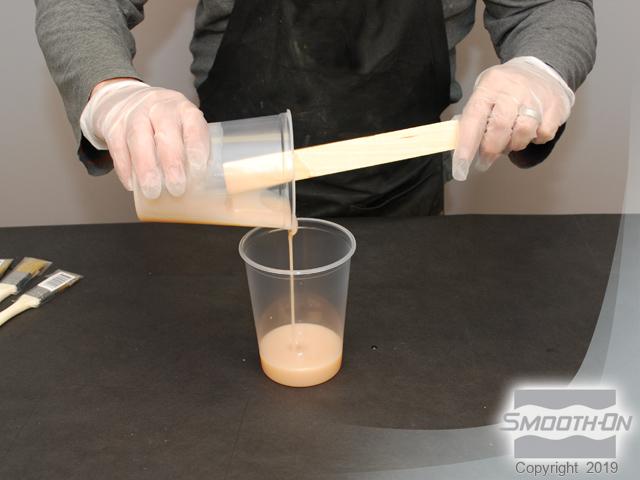

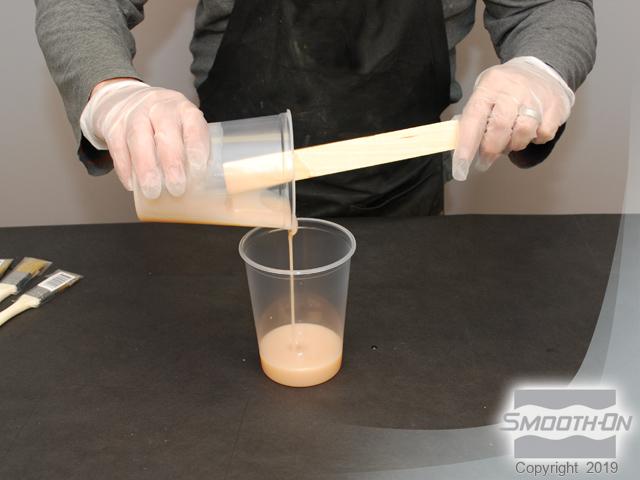

Careful mixing technique is employed. Contents are poured into a new mixing container and mixed thoroughly again.

Contents are poured into a new mixing container and mixed thoroughly again. Epsilon® is brushed onto the surface of the model.

Epsilon® is brushed onto the surface of the model. The material wets out evenly over the surface.

The material wets out evenly over the surface. Epsilon® can be brushed up onto vertical surfaces.

Epsilon® can be brushed up onto vertical surfaces. The model is completely coated and allowed to partially cure for 1 hour.

The model is completely coated and allowed to partially cure for 1 hour. After 1st layer becomes “tacky hard”, a second batch of Epsilon® is measured and mixed.

After 1st layer becomes “tacky hard”, a second batch of Epsilon® is measured and mixed. So-Strong® Blue will be added to this layer as to make it easier to differentiate from the first layer.

So-Strong® Blue will be added to this layer as to make it easier to differentiate from the first layer. So-Strong® colors mix easily into Epsilon® Parts A and B.

So-Strong® colors mix easily into Epsilon® Parts A and B. Blue Epsilon® layer ensures a thorough coating over first layer.

Blue Epsilon® layer ensures a thorough coating over first layer. Both layers of Epsilon® are allowed to cure for 16 hours before applying Mold Max® 25 silicone rubber mold material.

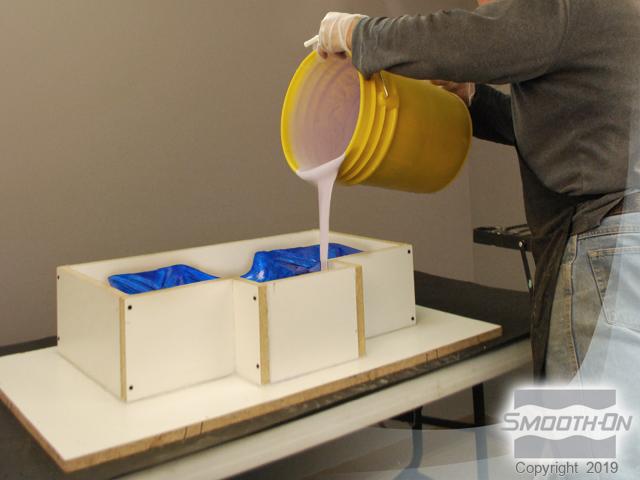

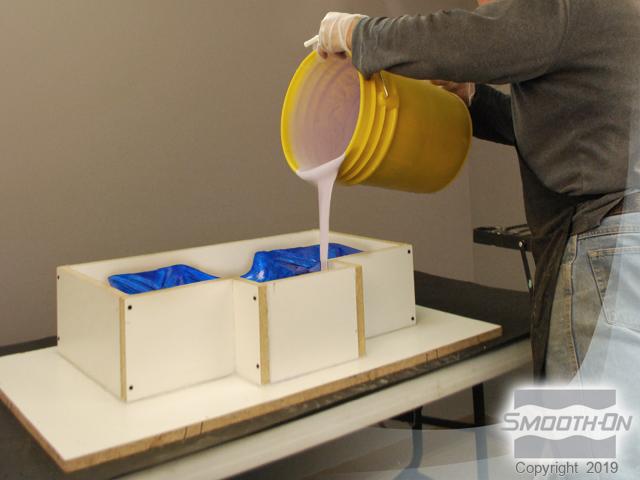

Both layers of Epsilon® are allowed to cure for 16 hours before applying Mold Max® 25 silicone rubber mold material. A mold box is assembled and Mold Max® 25 is poured over the Epsilon® coated model.

A mold box is assembled and Mold Max® 25 is poured over the Epsilon® coated model. Once the Mold Max® 25 is cured, the original model is demolded and then can be stored for future use.

Once the Mold Max® 25 is cured, the original model is demolded and then can be stored for future use. Flex Foam-It!® VIII is mixed and poured into the mold cavity.

Flex Foam-It!® VIII is mixed and poured into the mold cavity. A Sonite® Wax coated board is screwed down on the mold to force back pressure on the expanding foam. This ensures even distribution of foam in the mold.

A Sonite® Wax coated board is screwed down on the mold to force back pressure on the expanding foam. This ensures even distribution of foam in the mold. Once cured, the Flex Foam-It!® VIII pulls easily out of the mold.

Once cured, the Flex Foam-It!® VIII pulls easily out of the mold. The Flex Foam-It! VIII reflects perfect detailed captured from the original model and ready for production.

The Flex Foam-It! VIII reflects perfect detailed captured from the original model and ready for production.