PMC™-724

Used by artists and industry the world over for a variety of design, casting and special effects applications, PMC™-724 is by far the most versatile urethane rubber compound available on the market today. It is inexpensive, mixes and pours easily, and will cure to a durable rubber with negligible shrinkage. Low viscosity ensures flawless pick-up of even the finest detail with minimal bubble entrapment.

Features

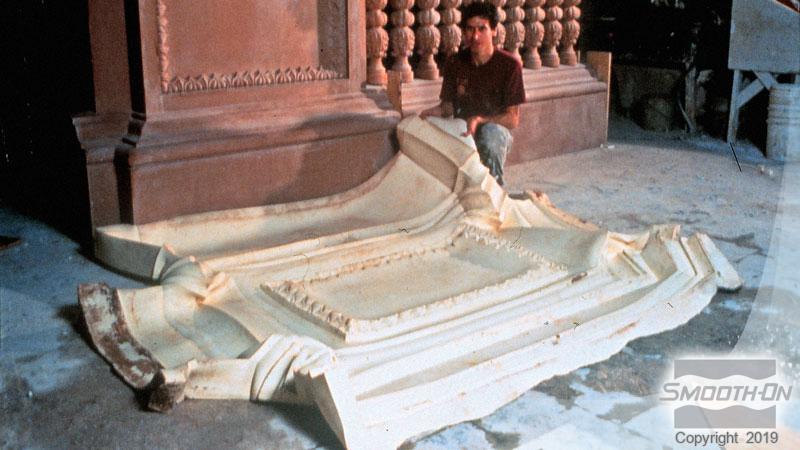

PMC™-724 PUTS YOU IN CONTROL! Using optional ‘Part D’, you can thicken PMC™-724 to a paste-like consistency for vertical surface brush-on applications or for getting into those hard-to-reach undercuts. If you like to work with a more flexible rubber, optional ‘Part C’ (SO-FLEX™) is available to soften PMC™-724 all the way down to a Shore A6. Typical applications include reproducing sculpture (lost wax process), creating special effects, making fiberglass panel & part molds, on-site architectural restoration and new construction molds. A variety of colors and special effects can be achieved by adding SO-Strong™ urethane colorants.

Important: This rubber will last and perform in production, often for hundreds of castings (depending on what you are casting into the mold). It also exhibits good physical properties and chemical resistance. But PMC-724™ does not have a long “library life”. Molds will soften and revert to a liquid within 2 – 5 years, depending on exposure to moisture. Smooth-On makes many different mold rubbers that offer a very long library life (25 years and more depending on application). Contact Smooth-On for information about its complete line of silicone and polyurethane mold rubbers.

FOR COMMERCIAL/INDUSTRIAL USE ONLY

› Click here for more PMC™ rubber products.

Instructions

Preparation - Store and use at room temperature (73°F/23°C). Material has a limited shelf life and should be used as soon as possible. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Good ventilation (room size) is necessary.

Some Materials Must Be Sealed - Models should be clean and dry. Polyurethane rubbers are adhesive and will bond to many surfaces if not properly prepared. Models made of porous materials (such as plaster, concrete, wood, etc.) must be sealed prior to applying a release agent. Sonite Wax™ (available from Smooth-On) is suitable for sealing porous surfaces. Apply two thin layers of wax and let dry. A high quality shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA.

Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent.

Applying A Release Agent - A release agent is necessary to release the cured rubber from your model. Use a release agent specifically made for mold making/casting. SmoothOn’s Universal™ Mold Release agent is ideal for most applications (available from Smooth-On or a Smooth-On distributor).

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

IMPORTANT: Shelf life of product is drastically reduced after opening. Immediately replacing the lids on both containers after dispensing product will prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal, glass or plastic. Materials should be stored and used in a warm environment (73°F/23°C).

You must mix Part B thoroughly before you begin. The mix ratio for this product is 1 part A to 10 parts B. You must use an accurate scale to weigh the components of PMC™-724. Use only a triple beam balance or gram scale. After dispensing the required amounts of Parts A and B into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times.

If Mixing Large Quantities (16 lbs./7 kgs. or more) at one time, use a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again. Although PMC™- 724 is formulated to minimize air bubbles in the cured mold, vacuum degassing will further reduce entrapped air. This is usually not necessary.

Pouring - For best results, pour the mixture in a single spot at the lowest point of the mold. Let the rubber seek its level, filling the detail and undercuts of your model. A uniform flow will help minimize entrapped air.

Curing - Allow the mold to cure overnight (at least 16 hours) at room temperature (73°F/23°C) before demolding. The mold will cure faster at higher temperatures and will cure slower at lower temperatures. Do not cure the mold where the temperature is less than 65°F/18°C.

Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. Smooth-On liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor. Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. PMC™-724 is not suitable for production casting of concrete. We recommend Vytaflex™ series rubber or other rubber that has superior abrasion resistance.

Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored. The physical life of the rubber depends on how you use it. Contact Smooth-On directly with questions about this material relative to your application.

Mold Life - PMC™-724 is not a permanent mold material and has limited library life. Cured rubber will last and perform in production, often for hundreds of castings (depending on what you are casting into the mold). However, rubber will soften with age due to ambient moisture in the air and should be discarded before becoming too soft to handle. With proper care, PMC™-724 rubber should not soften appreciably for 2-4 years.