How To Make a Sea Anemone Using Smooth‑On Silicone

Step 4: Preparing Mold for Casting

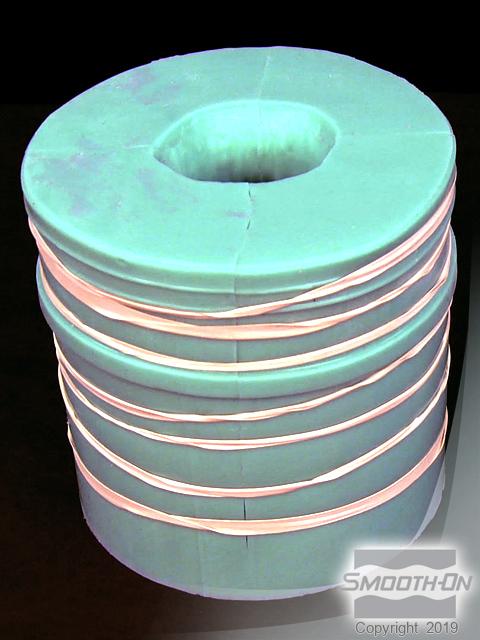

To prepare the mold for casting, align the cut seams and use rubber bands to close the mold.

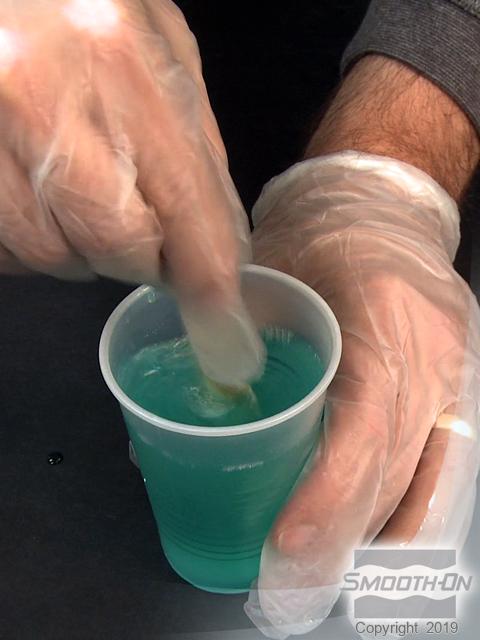

Since we will pour an EcoFlex silicone casting, we need to apply a release agent to prevent bonding. Because it will be difficult to reach all of the thin tentacle areas of the mold, a liquid release agent is your best option. Combine 2 parts isopropyl alcohol and 1 part dish washing soap. Mix the alcohol and soap together until blended thoroughly.

Rotate the mixture to thoroughly coat the tentacle cavities. Then, thoroughly drain the excess release liquid. Allow it to dry for 30 minutes before mixing and pouring your rubber casting.