C mpare

T

mpare

T

l

l

Key Differences

| Product Type |

|

|

| Mixed Viscosity | Dough | 1,100 cps |

| Pot Life | 90 minutes | 4 minutes |

| Cure Time | 16 hours | 48 hours |

| Shore D Hardness | 85 | — |

| Shore A Hardness | — | 60 |

| Specific Volume | 17.3 cu. in./lb. | 25.7 cu. in./lb. |

| Color | Grey | White |

Disclaimer

Although we do our best to ensure accuracy, Smooth-On offers no warranties, promises, and/or representations of any kind, either expressed or implied, as to the accuracy, completeness, or reliability of the information contained on this Compare Tool, nor suitability of the information contained herein to your particular circumstances. Smooth-On assumes no liability for losses or damages of whatever nature (direct, indirect, consequential or other) associated with your use, or inability to use, the Compare Tool, or from your use (or failure to use) the information contained herein. Other useful tools include product technical bulletins and our extensive FAQ section. You can also contact our technical support team.All Technical Data

| Free Form™ Habitat™ Fire Safe™ | Simpact™ 60A | |

|---|---|---|

| Product Type |

|

|

| Mixed Viscosity | Dough | 1,100 cps |

| Mix Ratio By Volume | 1A:1B | 1A:1B |

| Mix Ratio By Weight | 1A:1B | 100A:94B |

| Pot Life | 90 minutes | 4 minutes |

| Handling Time | — | 2 hours |

| Cure Time | 16 hours | 48 hours |

| Shore D Hardness | 85 | — |

| Shore A Hardness | — | 60 |

| Specific Gravity | 1.44 g/cc | 1.08 g/cc |

| Specific Volume | 17.3 cu. in./lb. | 25.7 cu. in./lb. |

| Color | Grey | White |

| Die C Tear Strength | — | 142 pli |

| Tensile Strength | — | 990 psi |

| Elongation @ Break | — | 400 % |

| 100% Modulus | — | 312 psi |

| Shrinkage | — | <.007 in. / in. |

| Heat Deflection Temp | 160 °F | — |

| Heat Deflection With Post Cure | 212 °F | — |

Product Description

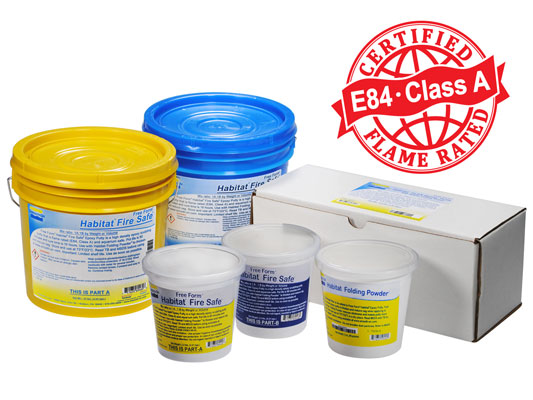

Free Form™ Habitat™ Fire Safe™

Free Form™ Habitat™ Fire Safe™ epoxy putty is a high density epoxy sculpting putty that is flame rated (E84, Class A). Habitat™ Fire Safe™ is solvent-free and contains no VOC’s. Working time is 90 minutes and cure time is 16 hours at room temperature (73° F/23° C). Epoxy cures to a very hard, flame and heat resistant material that is easily painted. Habitat™ Fire Safe™ does not contain any carcinogens (cancer causing agents).

Simpact™ 60A

Simpact™ 60A urethane is a low odor, fast-setting urethane elastomer which offers very high tear strength, impact resistance and wear resistance. Simpact™ urethanes are phthalate free, mercury free and MOCA free. Simpact™ urethanes pour easily. Working time is 4 minutes, handling time is 2 hours and full cure time is 48 hours at room temperature.

Cured rubber has exceptional performance characteristics and dimensional stability. Simpact™ urethanes can be colored with SO-Strong™, UVO™ or Ignite™ colorants. Simpact™ urethanes are suitable for making impact resistant props, prototypes and display pieces.

This material may congeal if exposed to cold temperatures. To reconstitute, Part A & B must be heated to 90°F (33°C) then thoroughly mixed to an even consistency.