C mpare

T

mpare

T

l

l

Key Differences

| Product Type |

|

|

| Mixed Viscosity | Variable | 23,000 cps |

| Mix Ratio By Volume | 3 Parts Powder : 1 Part Water By Volume | N/A (gram scale required) |

| Pot Life | 20 minutes | 30 minutes |

| Cure Time | 90 minutes | 3 hours |

| Shore D Hardness | — | 90 |

| Color | White | Grey |

Disclaimer

Although we do our best to ensure accuracy, Smooth-On offers no warranties, promises, and/or representations of any kind, either expressed or implied, as to the accuracy, completeness, or reliability of the information contained on this Compare Tool, nor suitability of the information contained herein to your particular circumstances. Smooth-On assumes no liability for losses or damages of whatever nature (direct, indirect, consequential or other) associated with your use, or inability to use, the Compare Tool, or from your use (or failure to use) the information contained herein. Other useful tools include product technical bulletins and our extensive FAQ section. You can also contact our technical support team.All Technical Data

| Matrix Dryve™ | EpoxAcast™ 655 + 101 Hardener | |

|---|---|---|

| Product Type |

|

|

| Mixed Viscosity | Variable | 23,000 cps |

| Mix Ratio By Volume | 3 Parts Powder : 1 Part Water By Volume | — |

| Mix Ratio By Weight | 100 Parts Powder : 27 Parts Water by Weight | 100A:10B |

| Pot Life | 20 minutes | 30 minutes |

| Cure Time | 90 minutes | 3 hours |

| Shore D Hardness | — | 90 |

| Specific Gravity | — | 1.66 g/cc |

| Specific Volume | 17.45 cu. in./lb. | 16.7 cu. in./lb. |

| Color | White | Grey |

| Tensile Strength | 3300 - 5500 psi | — |

| Tensile Modulus | — | 2,040,000 psi |

| Ultimate Tensile | — | 4,810 psi |

| Tensile Elongation | — | 0.54 % |

| Compressive Strength | 6500 - 9500 psi | 12,500 psi |

| Compressive Modulus | — | 125,500 psi |

| Flexural Strength | — | 7,660 psi |

| Flexural Modulus | — | 1,403,000 psi |

| Shrinkage | — | 0.0006 in. / in. |

| Heat Deflection Temp | — | 135 °F |

| Useful Temperature (max) | 200 °F | — |

| Density | 99 lbs lb/ft³ | — |

| Flexural Strength on 6 ply / 10 oz. Laminate | 7500 - 9800 psi | — |

| Freeze / Thaw Resistance | 300 cycles | — |

| Impact Resistance | 175 in lb / in² | — |

| Thermal Conductivity | — | 0.675 W/M*K |

| Water Absorption | 0.5 ‰ after 24 hour water soak | — |

Product Description

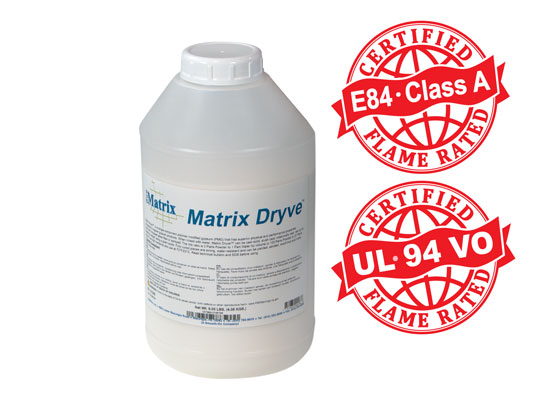

Matrix Dryve™

Matrix Dryve™ is a versatile all-powder polymer modified gypsum system that has superior physical and performance properties compared to regular gypsum products. It is an “all-powder” alternative to our original Matrix™ NEO powder/liquid system.

EpoxAcast™ 655 + 101 Hardener

EpoxAcast™ 655 (formerly Metalset™ A-30) is a versatile aluminum filled castable epoxy resin that is very hard and strong. It is dimensionally stable, even when mass cast up to 512 in³ / 8,390 cm³.