C mpare

T

mpare

T

l

l

Key Differences

| Product Type |

|

|

| Mixed Viscosity | Variable | 2,600 cps |

| Cure Time | 90 minutes | 16 hours |

| Shore A Hardness | — | 45 |

| Specific Volume | 17.45 cu. in./lb. | 24.7 cu. in./lb. |

| Color | White | Brown |

Disclaimer

Although we do our best to ensure accuracy, Smooth-On offers no warranties, promises, and/or representations of any kind, either expressed or implied, as to the accuracy, completeness, or reliability of the information contained on this Compare Tool, nor suitability of the information contained herein to your particular circumstances. Smooth-On assumes no liability for losses or damages of whatever nature (direct, indirect, consequential or other) associated with your use, or inability to use, the Compare Tool, or from your use (or failure to use) the information contained herein. Other useful tools include product technical bulletins and our extensive FAQ section. You can also contact our technical support team.All Technical Data

| Matrix Dryve™ | Compat™ 45 | |

|---|---|---|

| Product Type |

|

|

| Mixed Viscosity | Variable | 2,600 cps |

| Mix Ratio By Volume | 3 Parts Powder : 1 Part Water By Volume | 1A:1B |

| Mix Ratio By Weight | 100 Parts Powder : 27 Parts Water by Weight | 85A:100B |

| Pot Life | 20 minutes | 25 minutes |

| Cure Time | 90 minutes | 16 hours |

| Shore A Hardness | — | 45 |

| Specific Gravity | — | 1.12 g/cc |

| Specific Volume | 17.45 cu. in./lb. | 24.7 cu. in./lb. |

| Color | White | Brown |

| Die C Tear Strength | — | 101 pli |

| Tensile Strength | 3300 - 5500 psi | 629 psi |

| Elongation @ Break | — | 772 % |

| 100% Modulus | — | 137 psi |

| Compressive Strength | 6500 - 9500 psi | — |

| Shrinkage | — | <0.001 in. / in. |

| Useful Temperature (max) | 200 °F | — |

| Density | 99 lbs lb/ft³ | — |

| Flexural Strength on 6 ply / 10 oz. Laminate | 7500 - 9800 psi | — |

| Freeze / Thaw Resistance | 300 cycles | — |

| Impact Resistance | 175 in lb / in² | — |

| Water Absorption | 0.5 ‰ after 24 hour water soak | — |

Product Description

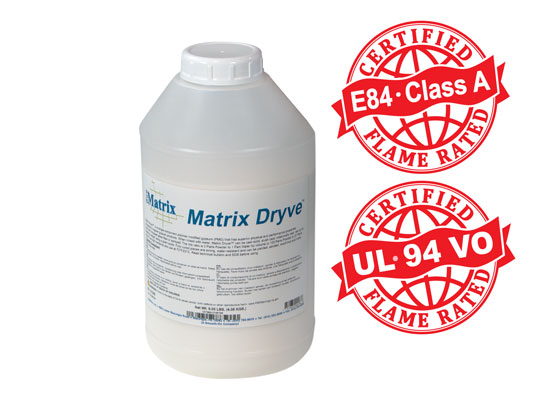

Matrix Dryve™

Matrix Dryve™ is a versatile all-powder polymer modified gypsum system that has superior physical and performance properties compared to regular gypsum products. It is an “all-powder” alternative to our original Matrix™ NEO powder/liquid system.

Compat™ 45

Compat™ 45 urethane is a unique urethane rubber which will not inhibit the cure of most Smooth-On platinum or tin cure silicone rubbers. It features a low viscosity for easy mixing and pouring and cures with minimal bubble entrapment. Mix ratio is 1A:1B by volume (85A:100B by weight), pot life is 25 minutes and the rubber cures with an ultimate Shore hardness of Shore 45A. Cured rubber is dimensionally stable (low shrinkage), offers good wear resistance and excellent library life. Compat™ 45 can be used for a variety of applications including making molds to cast silicone prop body parts, animatronic skins and medical trainers, as well as for making rubber masters which can be molded using platinum or tin silicone without inhibition concerns.

Important; Do not use Ecoflex™ Gel, Ecoflex™ 00-10, Ecoflex™ Near Clear, Encapso-K, Rubber Glass™, Solaris™, Soma Foama™ or Sorta-Clear™ 12 or 37 with this product. They are not compatible and inhibition will result.