EpoxAcast™ Series

Castable Epoxy Resins

Castable epoxies are used for a variety of industrial applications. They are easy to use, contain no VOC’s and are solvent free. Compared to Smooth-Cast™ or TASK™ urethane plastics, EpoxAcast™ epoxies are generally harder, have higher compression strength as well as higher heat and abrasion resistance. They are also widely used for electrical encapsulation and bonding applications.

HIGHLIGHTS

EpoxAcast™ 650

Mineral Filled

EpoxAcast™ 650

Mineral Filled

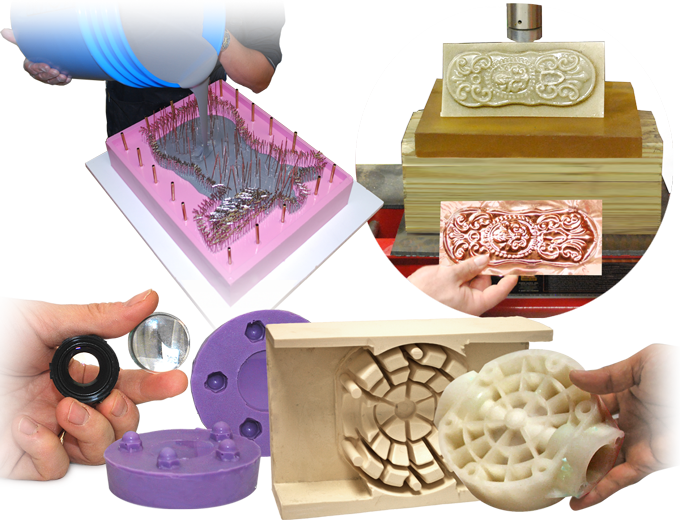

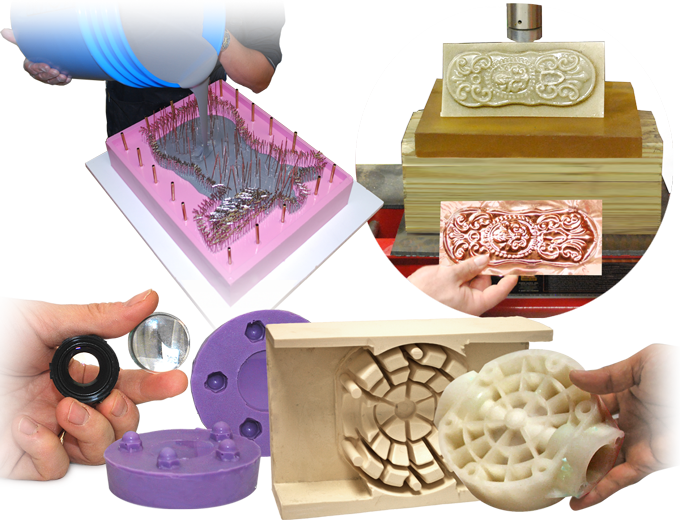

Low cost and versatile. Used for making hard dies for metal stamping, patterns, fixtures and for electrical encapsulation to extend the life cycles and enhance the performance of potted electronic devices. Features a low mixed viscosity for minimal bubble entrapment. Choose Fast, Medium, or Slow catalyst, as well as HT Hardener for higher heat resistance.

Gram Scale Required

Gram Scale Required

Low Cost Resin

Low Cost Resin

EpoxAcast™ 655

Metal Filled

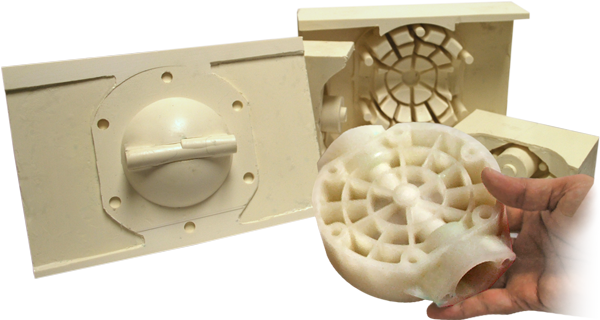

EpoxAcast™ 655

Metal Filled

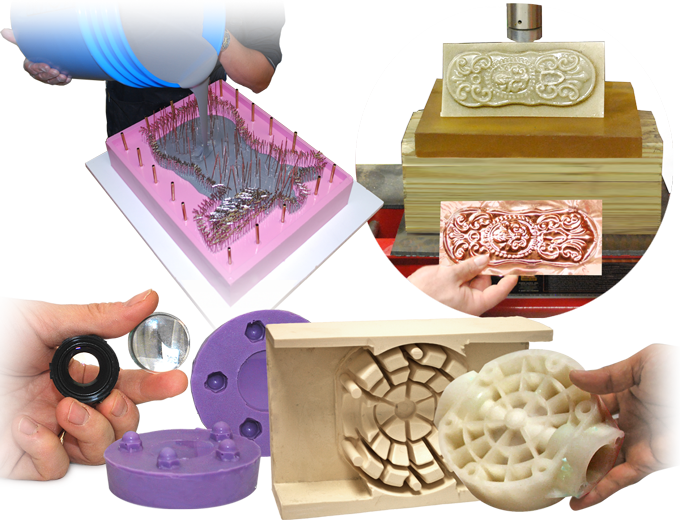

Versatile aluminum filled castable epoxy that is very hard and strong. It is dimensionally stable, even when mass cast up to 512 in³ / 8,390 cm³ . Make hard tooling, vacuum forming dies/molds, injection molds, foundry patterns, jigs, fixtures and metal forming dies.

Gram Scale Required

Gram Scale Required

Industrial Grade

Industrial Grade

EpoxAcast™ 670 HT

Highest Temperature Resistance

EpoxAcast™ 670 HT

Highest Temperature Resistance

Offers high heat resistance up to 350° F/177° C if post cure schedule is used. Ideal for making vacuum form molds, foundry patterns, forming dies & fixtures, hard rollers, industrial parts and high impact tools.

High Temp Resistance

High Temp Resistance

Gram Scale Required

Gram Scale Required

EpoxAcast™ 690

Optically Clear Epoxy

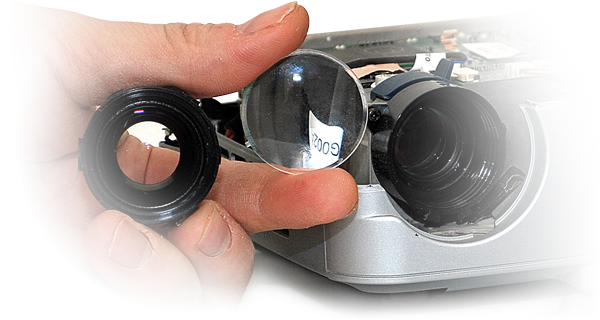

EpoxAcast™ 690

Optically Clear Epoxy

Ideal for making clear jewelry/beads or replacement lenses for kit cars and other applications requiring a rigid, clear finished product. EpoxAcast™ 690 can be colored with UVO™ or IGNITE™ colorants

Gram Scale Required

Gram Scale Required

EpoxAcast™ 692

Deep Pour

EpoxAcast™ 692

Deep Pour

EpoxAcast™ 692 Deep Pour allows for thicker single-stage pours, with a maximum casting thickness of 2” (5.08cm) when poured at an ambient temperature of 70°F / 21°C and using fans to cool the surface. This gives you the freedom to make river tables, bar tops and more, with the ease of a single pour.

Gram Scale Required

Gram Scale Required

Water White Clear

Water White Clear

Technical and Buying Information

| Select a Product Below | Pot Life | Cure Time | Heat Deflection Temp |

|---|---|---|---|

| › EpoxAcast™ 650 + 101 Hardener | 20 mins | 1 hr | 129 °F |

| › EpoxAcast™ 650 + 102 Hardener | 90 mins | 4 hrs | 129 °F |

| › EpoxAcast™ 650 + 103 Hardener | 3.5 hrs | 24 hrs | 129 °F |

| › EpoxAcast™ 650 + HT Hardener | 3 hrs |

Twenty Four Hours Followed By Post Cure |

187 °F |

| › EpoxAcast™ 650 BLACK + 101 Hardener | 20 mins | 1 hr | 129 °F |

| › EpoxAcast™ 650 BLACK + 102 Hardener | 90 mins | 4 hrs | 129 °F |

| › EpoxAcast™ 650 BLACK + 103 Hardener | 3.5 hrs | 24 hrs | 129 °F |

| › EpoxAcast™ 650 BLACK + HT Hardener | 3 hrs |

Twenty Four Hours Followed By Post Cure |

187 °F |

| › EpoxAcast™ 655 + 101 Hardener | 30 mins | 3 hrs | 135 °F |

| › EpoxAcast™ 655 + 102 Hardener | 75 mins | 9 hrs | 135 °F |

| › EpoxAcast™ 655 + 103 Hardener | 3.5 hrs | 24 hrs | 135 °F |

| › EpoxAcast™ 655 + HT Hardener | 4 hrs |

Twenty Four Hours Followed By Post Cure |

225 °F |

| › EpoxAcast™ 670 HT | 3 hrs |

Twenty Four Hours Followed By Post Cure |

350 °F |

| › EpoxAcast™ 690 | 5 hrs | 24 hrs | 115 °F |

| › EpoxAcast™ 692 Deep Pour | 12 hrs | – | 100 °F |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Make a Custom Charcuterie Cutting Board With EpoxAcast™ 690

Transform a normal cutting board into a unique decorative charcuterie serving board using EpoxAcast™ 690

Using EpoxAcast™ 692 Deep Pour to Make an Epoxy Table

EpoxAcast™ 692 Deep Pour allows you to pour up to 2 inches of epoxy in a single pour

How To Make Cherry Burl and Epoxy Rings Using EpoxAcast™ 690

Chris demonstrates how he turns these gorgeous "earth rings" using EpoxAcast™ 690

How to Make a Concrete and Epoxy Lagoon Aquarium Table

Learn how to use concrete in combination with clear epoxy resin to create an aquarium table.

How To Make a Waterfall Table Using EpoxAcast™ 690

Learn how to make a waterfall table using EpoxAcast™ clear liquid epoxy

How To Make a Colored Pencil Bowl Using EpoxAcast™ 690 Epoxy

Learn how to create a diy epoxy bowl with embedded colored pencils.

How To Make a River Table Using Clear Epoxy Casting Resin and Reclaimed Wood

How to use a piece of reclaimed cedar to create a beautiful river table

How To Make an Epoxy Flexible Using Flexer™ Epoxy Flexibilizer

Flexer® is an additve for Smooth-On epoxies which makes the resultant castings flexible.

How To Make an Epoxy Table Using EpoxAcast™ 690 Epoxy Resin

Milo shows how he makes a very unique, creative epoxy table top using EpoxAcast™ 690.

How Vacuum Formed Packaging Is Made Using a High Temp Epoxy Tool

Learn how clamshell packaging is made using an epoxy vacuum forming tool

What Have Other People Done With These Products?

Star Wars Han Solo in Carbonite Refrigerator

Learn How Frank Ippolito Created This Full Size Star Wars Themed Fridge