C mpare

T

mpare

T

l

l

Key Differences

| Product Type |

|

|

| Mixed Viscosity | Dough | 600 cps |

| Mix Ratio By Volume | 1A:1B | N/A (gram scale required) |

| Pot Life | 90 minutes | 4.5 hours |

| Cure Time | 24 hours | 7 days |

| Shore D Hardness | — | 80 |

| Shore A Hardness | 90 | — |

| Specific Volume | 17.9 cu. in./lb. | 26.7 cu. in./lb. |

| Color | Light Brown | Clear |

Disclaimer

Although we do our best to ensure accuracy, Smooth-On offers no warranties, promises, and/or representations of any kind, either expressed or implied, as to the accuracy, completeness, or reliability of the information contained on this Compare Tool, nor suitability of the information contained herein to your particular circumstances. Smooth-On assumes no liability for losses or damages of whatever nature (direct, indirect, consequential or other) associated with your use, or inability to use, the Compare Tool, or from your use (or failure to use) the information contained herein. Other useful tools include product technical bulletins and our extensive FAQ section. You can also contact our technical support team.All Technical Data

| Free Form™ Habitat™ Flex FR | Crystal Clear™ 206 | |

|---|---|---|

| Product Type |

|

|

| Mixed Viscosity | Dough | 600 cps |

| Mix Ratio By Volume | 1A:1B | — |

| Mix Ratio By Weight | 1A:1B | 100A:90B |

| Pot Life | 90 minutes | 4.5 hours |

| Cure Time | 24 hours | 7 days |

| Shore D Hardness | — | 80 |

| Shore A Hardness | 90 | — |

| Specific Gravity | 1.55 g/cc | 1.036 g/cc |

| Specific Volume | 17.9 cu. in./lb. | 26.7 cu. in./lb. |

| Color | Light Brown | Clear |

| Tensile Strength | — | 2,500 psi |

| Tensile Modulus | — | 73,200 psi |

| Elongation @ Break | — | 10 % |

| Compressive Strength | — | 6,385 psi |

| Compressive Modulus | — | 40,000 psi |

| Flexural Strength | — | 10,650 psi |

| Flexural Modulus | — | 200,000 psi |

| Shrinkage | — | 0.002 in. / in. |

| Heat Deflection Temp | — | 120 °F |

| Index of Refraction at 20°C | — | 1.49962 |

| Index of Refraction at 25°C | — | 1.49894 |

Product Description

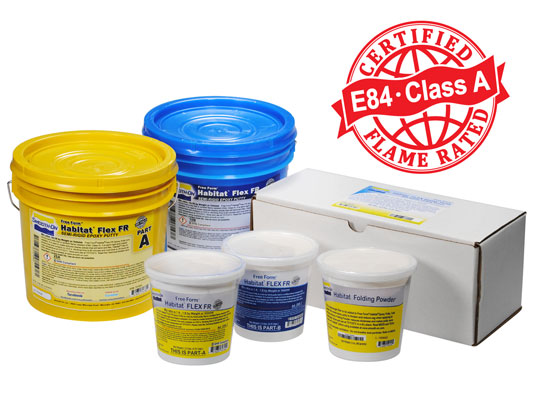

Free Form™ Habitat™ Flex FR

Free Form™ Habitat™ Flex FR Epoxy Putty is a mix-and-apply-by-hand putty that is that is certified flame resistant (E84, Class A) and is used to create display elements that are semi-rigid and extremely tough. It is also used for industrial bonding applications. Habitat™ Flex FR is solvent free and contains no VOC’s. Working time is 90 minutes and handling time is 24 hours at room temperature (73°F/23°C). Cured epoxy has some flexibility with excellent impact resistance and abrasion resistance.

Habitat™ Flex FR forms a permanent bond to a variety of surfaces including foam, steel and stainless steel, wood, PVC, ABS plastic, concrete and more. It withstands freeze/thaw cycles for exterior applications. When using as an adhesive do not use folding powder. It is easy to paint with acrylic paints or stains. Use to make perfectly detailed tree branches, planks and other themed elements for zoos and amusement parks. Because finished elements are semirigid, reptiles and birds can comfortably grip them without affecting the material.

Use with or without Habitat™ Folding Powder™ – mix equal parts A+B and apply Habitat™ Flex FR. For thickening, add Folding Powder™ into epoxy putty. Folding Powder™ reduces stickiness and makes the epoxy more handleable. Once putty is applied, it can be stamped with a silicone rubber stamp to create repeating patterns with intricate detail over a large surface area. Surface can be smoothed with alcohol or water. New Habitat™ Flex FR will bond to cured Habitat™ Flex FR without delamination.

Crystal Clear™ 206

Crystal Clear™ 206 is a water white clear and made specifically for applications that require clarity. These rigid urethane casting resins differ only in working and demold times. Low viscosity ensures easy mixing and pouring. Crystal Clear™ resins cure at room temperature* with negligible shrinkage.

CAUTION: NOT FOR HOME USE. THIS PRODUCT IS FOR INDUSTRIAL USE ONLY. With adequate local exhaust ventilation, respiratory protection is not normally required when using this product. Where risk assessment shows air-purifying respirators are appropriate, follow OSHA respirator regulations and European Standards EN 141, 143 and 371. Protective clothing (gloves and long sleeves) is required to minimize the risk of dermal sensitization. If breathing is affected or a dermal rash develops, immediately cease using this product and seek medical attention. Read SDS before using.