Mold Star™ 30

Mold Star™ mold rubbers are easy to use platinum silicones which are mixed 1A:1B by volume (no weighing scale necessary). Mold Star™ silicones feature relatively low viscosities and vacuum degassing is not required for most applications. Mold Star™ 30 is a harder material, with a 30A Shore hardness.

Features

Mold Star™ silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage. Molds made with Mold Star™ will last a long time in your mold library and are good for casting wax, gypsum, resins, and other materials. Cured Mold Star™ rubber is heat resistant up to 450°F (232°C) and is suitable for casting low-temperature melt metal alloys. Note: Mold Star™ rubbers are not intended for brush-on moldmaking.

Note: This product will not cure against surfaces containing sulfur, even when sealed.

› Click here for more Mold Star™ silicone products.

Instructions

Safety - Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Wear vinyl gloves only. Latex gloves will inhibit the cure of the rubber. Store and use material at room temperature (73°F/23°C). Warmer temperatures will drastically reduce working time and cure time. Storing material at warmer temperatures will also reduce the usable shelf life of unused material. These products have a limited shelf life and should be used as soon as possible.

Cure Inhibition - Addition cured silicone rubber may be inhibited by certain contaminants in or on the pattern to be molded resulting in tackiness at the pattern interface or a total lack of cure throughout the mold. Latex, sulfur clays, certain wood surfaces, newly cast polyester, epoxy or urethane rubber may cause inhibition. If compatibility between the rubber and the surface is a concern, a small-scale test is recommended. Apply a small amount of rubber onto a non-critical area of the pattern. Inhibition has occurred if the rubber is gummy or uncured after the recommended cure time has passed. To prevent inhibition, one or more coatings of a clear acrylic lacquer applied to the model surface is usually effective. Allow any sealer to thoroughly dry before applying rubber.

Even with a sealer, Mold Star™ silicones will not cure against surfaces containing sulfur. If you are not sure if your clay contains sulfur, do a small compatibility test before using for an important project.

Applying A Release Agent - Although not usually necessary, a release agent will make demolding easier when casting into most surfaces. Ease Release™ 200 is a proven release agent for releasing silicone from silicone or other surfaces. Mann Ease Release™ products are available from Smooth-On or your Smooth-On distributor.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Measuring & Mixing - Before you begin, pre-mix Part A and Part B separately. After dispensing required amounts of Parts A and B into mixing container (1A:1B by volume), mix thoroughly making sure that you scrape the sides and bottom of the mixing container several times. The rubber should be a uniform color with no streaks.

Optional... Vacuum Degassing - Although not necessary, vacuum degassing helps eliminate any entrapped air in pourable silicone rubber. After mixing parts A and B, vacuum material for 2-3 minutes at 29 inches of mercury, making sure that you leave enough room in container for product expansion.

Pouring - For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its own level. A uniform flow will help minimize entrapped air. If using as a mold material, the liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface.

Curing - Mold Star™ 30 must be allowed to cure for 6 hours at room temperature (73°F/23°C) before demolding.

Heat Curing - Time to demold can be reduced by applying mild heat. Example: After pouring Mold Star™ 16 rubber at room temperature, place the mold in a hot box or industrial oven at 140°F (60°C). This will reduce the time to demold of a 1/2” (1.3 cm) thick section to about 10 minutes. Note: Time will vary depending on mold thickness.

Adding an appropriate amount of Plat-Cat™ cure accelerator will also reduce demold time. The pot life and cure times can be extended using Slo-Jo™ cure retarder. Do not cure rubber where temperature is less than 65°F/18°C.

Mold Performance & Storage - The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Casting abrasive materials can quickly erode mold detail, while casting non-abrasive materials (wax) will not affect mold detail. Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment.

Related Categories: Silicone Rubber - Platinum Cure

Related Series: Mold Star™ Series – Easy to Use Silicone Mold Rubber

How-To Articles

How Vacuum Formed Packaging Is Made Using a High Temp Epoxy Tool

Learn how clamshell packaging is made using an epoxy vacuum forming tool

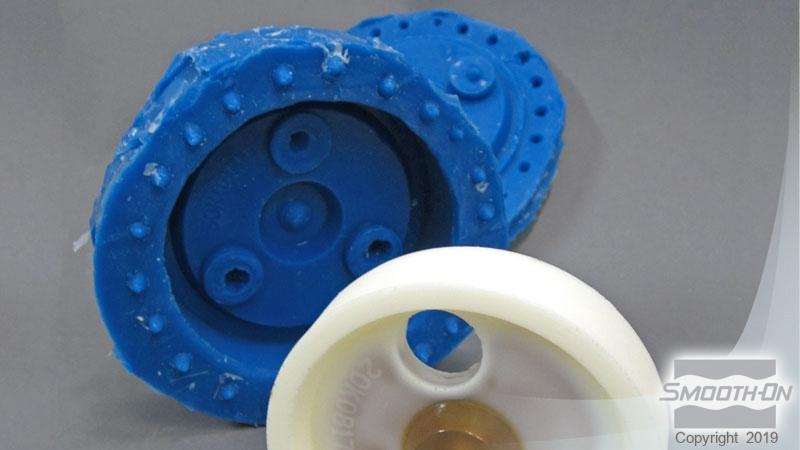

How To Make a Custom Steering Wheel: Part 1, Silicone Moldmaking

Milo shows how you can make a silicone mold of a steering wheel to create an aftermarket part.

How To Make a Gang Mold For Soap Production

This DIY tutorial shows how to make a gang mold of multiple models for production casting of soap.

How To Make a Two Piece Silicone Mold of a Knife

We demonstrate using Mold Star 30 silicone, a platinum silicone for mold making...

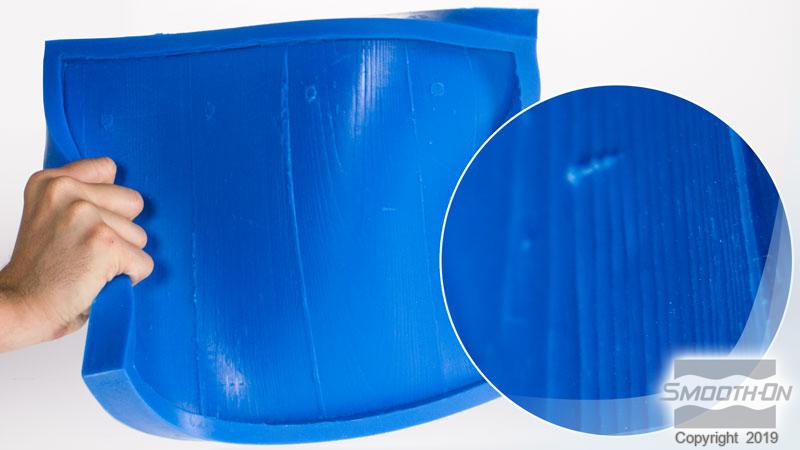

How To Create a Silicone Rubber Texture Mat for GFRC Panels

Granary wall inside the barn features woodgrain textures that can be duplicated onto GFRC panels for a shower install.

How To Make a Replacement Car Lens Using Crystal Clear 202

How you can replicate a tail light lens of any car using optically-clear resin.

How To Choose The Right Method For Making a Rubber Mold

Discover the advantages and considerations behind block molds, brush-on molds, and cavity pour molds.

How To Make a Foam Prop Sword Using a Silicone 2 Part Mold

How a 3D printed master is used to pour a silicone mold for a prop sword