Rubber Glass™

Rubber Glass™ is a platinum-catalyzed silicone rubber product developed specifically for special effects and display applications. Two liquids (1 Part A + 1 Part B) are mixed together and poured into a container.

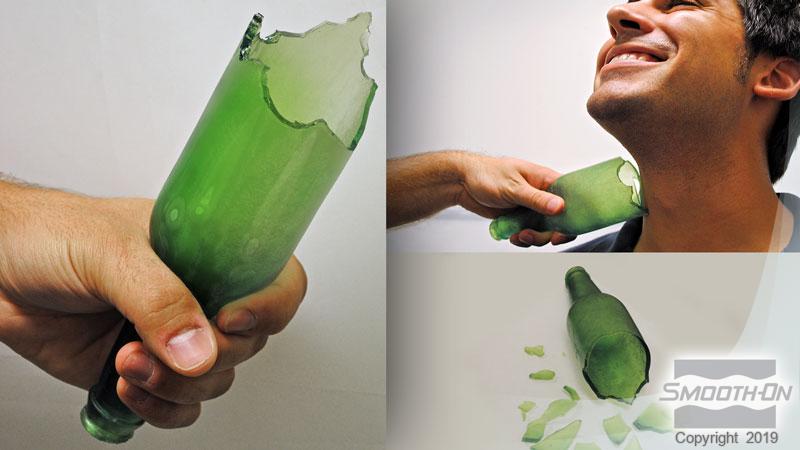

The mixture cures overnight to a solid water clear rubber that can then be easily broken or “crumbled” into pieces that look exactly like broken glass, ice or diamonds. Vibrant colors are possible by adding Silc-Pig™ liquid color pigments.

Rubber Glass™ can be used to create a variety of special effects (i.e. simulated broken glass where human contact is required) and model effects (i.e. simulated ice or water). It can also be used for electronic encapsulation applications.

Instructions

MEASURING & MIXING...

Materials should be stored and used in a warm environment (73°F/23°C). This product has a limited shelf life and should be use as soon as possible. Mixing containers and stirring sticks should be made of plastic and must be clean and dry. Wear safety glasses, long sleeves and vinyl gloves to minimize contamination risk.

Dispense One Part A and One Part B by weight or volume into mixing container. Mix thoroughly for at least three minutes, making absolutely sure that you scrape the sides and bottom of your container several times.

Do not whip or agitate material as this may cause air bubbles. If completely bubble free castings are required, vacuum degassing material prior to pouring will eliminate all bubbles.

POURING & CURING...

Pouring - Pour mixture into a plastic container or mold (ice cube trays or plastic cups made of polyethylene work well). If pouring into or over other surfaces, be aware that cure inhibition is possible (see section -“Cure Inhibition”). If casting into silicone molds, a release agent (Ease Release™ 200 available from Smooth-On) is required.

Curing - Let cure overnight at room temperature (73°F/23°C). Do not cure rubber where temperature is less than 65°F /18°C. You can cure the material faster by applying mild heat (150°F/60°C).

INHIBITION & PERFORMANCE...

Cure Inhibition - If compatibility between the rubber and the surface that you are pouring rubber over is a concern, a small scale test is recommended. Materials found to cause cure inhibition include sulfur-based modeling clays and latex rubber. If pouring Rubber Glass™ over a model surface that you think might cause inhibition, apply a “barrier coat” of clear acrylic lacquer sprayed directly over all surfaces that will come in contact with the Rubber Glass™ is usually effective.

Adhesion: Rubber Glass™ may stick to some surfaces such as glass. A coating of Ease Release™ 200 will facilitate release from any surface.

Material Performance - Once material has fully cured it can be removed from the container or mold. Cured Rubber Glass™ is now ready to be displayed as is or broken/crumbled for your specific application.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Rubber Glass™ Coverage Rates

| Amount | Poured at 0.25”(6.35mm) | Poured at 0.5”(12.7mm) |

|---|---|---|

| Trial Unit (4 lbs. /1.81 kg) | 3.17 ft2 (0.29 m2) | 1.58 ft2 (0.15 m2) |

| Gallon Unit (32 lbs. /14.51kg) | 25.4 ft2 (2.36 m2) | 12.7 ft2 (1.18 m2) |

| 5 Gallon Unit (107 lbs. / 48.53kg) | 85 ft2 (7.90 m2) | 42.5 ft2 (3.95 m2) |

Related Categories: Silicone Rubber - Platinum Cure

Related Series: Rubber Glass™ – Water-Clear Silicone Rubber

How-To Articles

How To Make an Arm Wound with Glass Debris

In this makeup effects video, we demonstrate how to make a fake cut or making a wound using Skin Tite on-skin silicone rubber.

How To Make a Face Wound with Glass Debris

Skin Tite® is a versatile two-component silicone rubber product that can be used as an "On Skin" Sculpting Medium.