How To Repair a Tractor Seat Using FlexFoam‑iT!™ 15

Overview

In this tutorial we show how FlexFoam-iT! 15 can be used to repair a damaged John Deere® tractor seat. FlexFoam-iT!™ 15 is a unique formulation which has a relatively long, 2 minute pot life. FlexFoam is part of our “Tuff Stuff” line, which is formulated for exceptional strength.

Materials Used in this Tutorial

- FlexFoam-iT! 15 "Tuff Stuff"

- Mixing Cups

- Stirring Stick

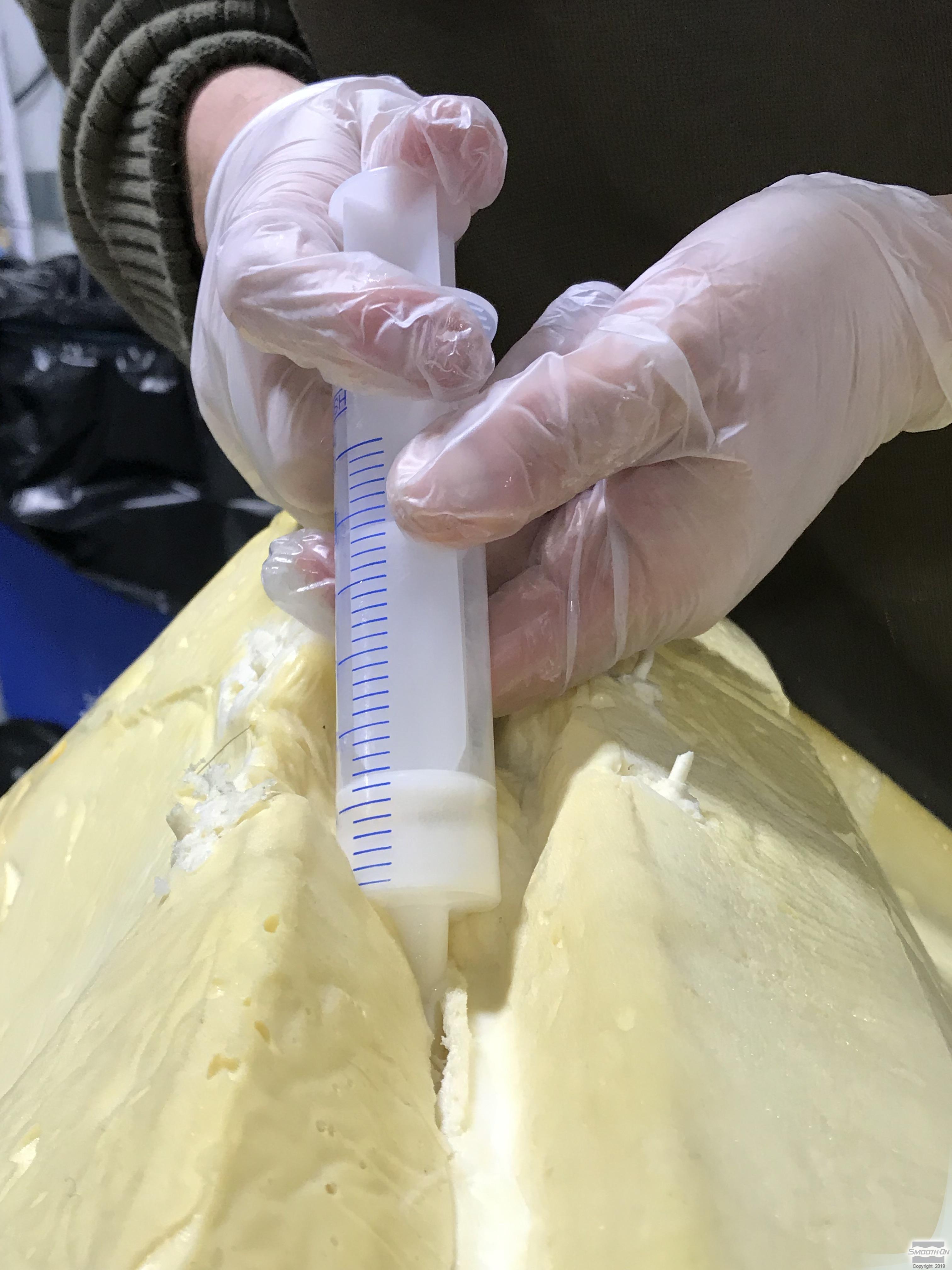

- Plastic Syringe

- Painters' Tape

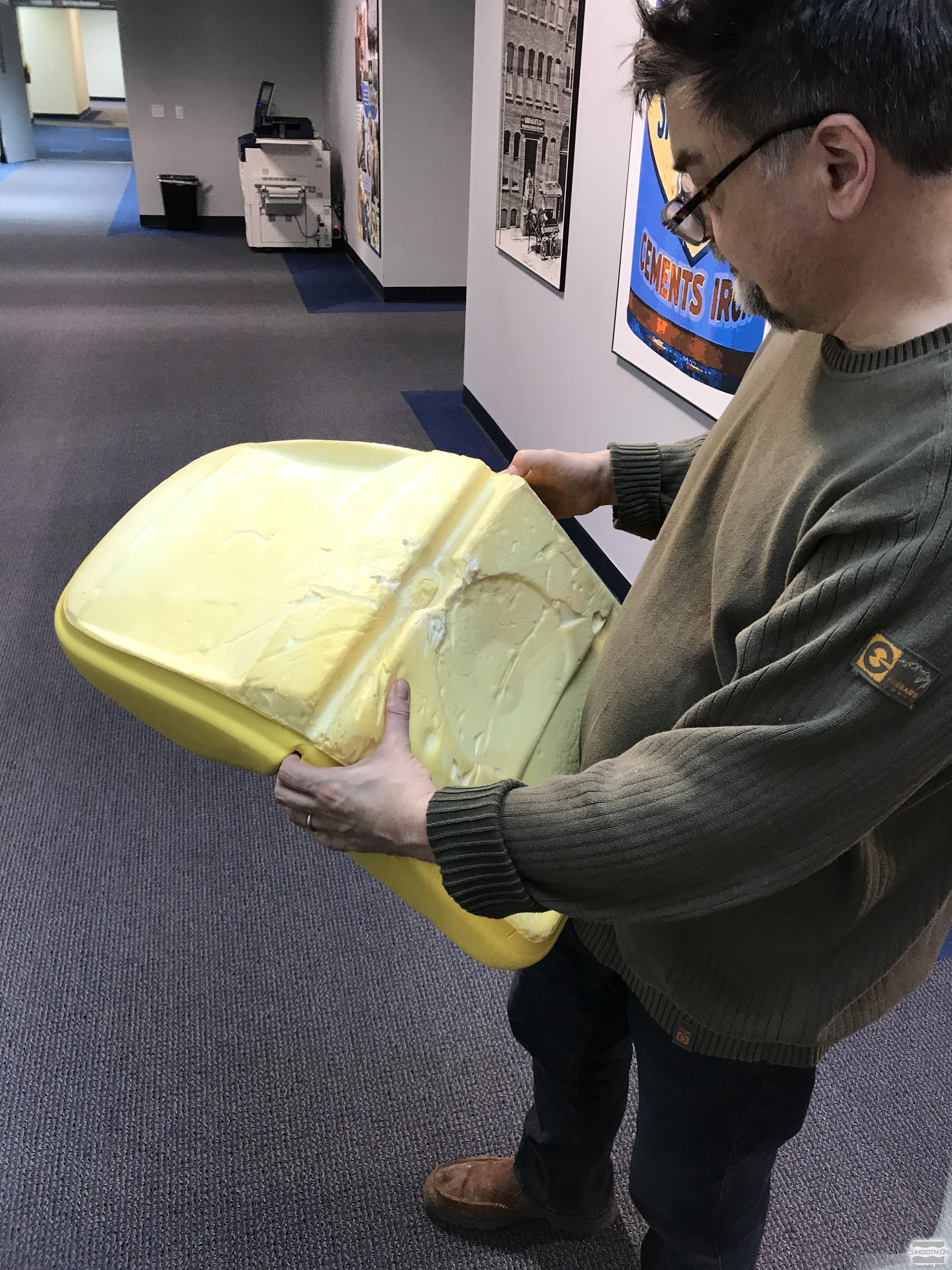

Step 1: Identify Areas to Repair

The foam seat of this tractor has extensive damage at the seam and inner filling. Injecting foam into the damaged area will increase comfort and close the gap at the seam.

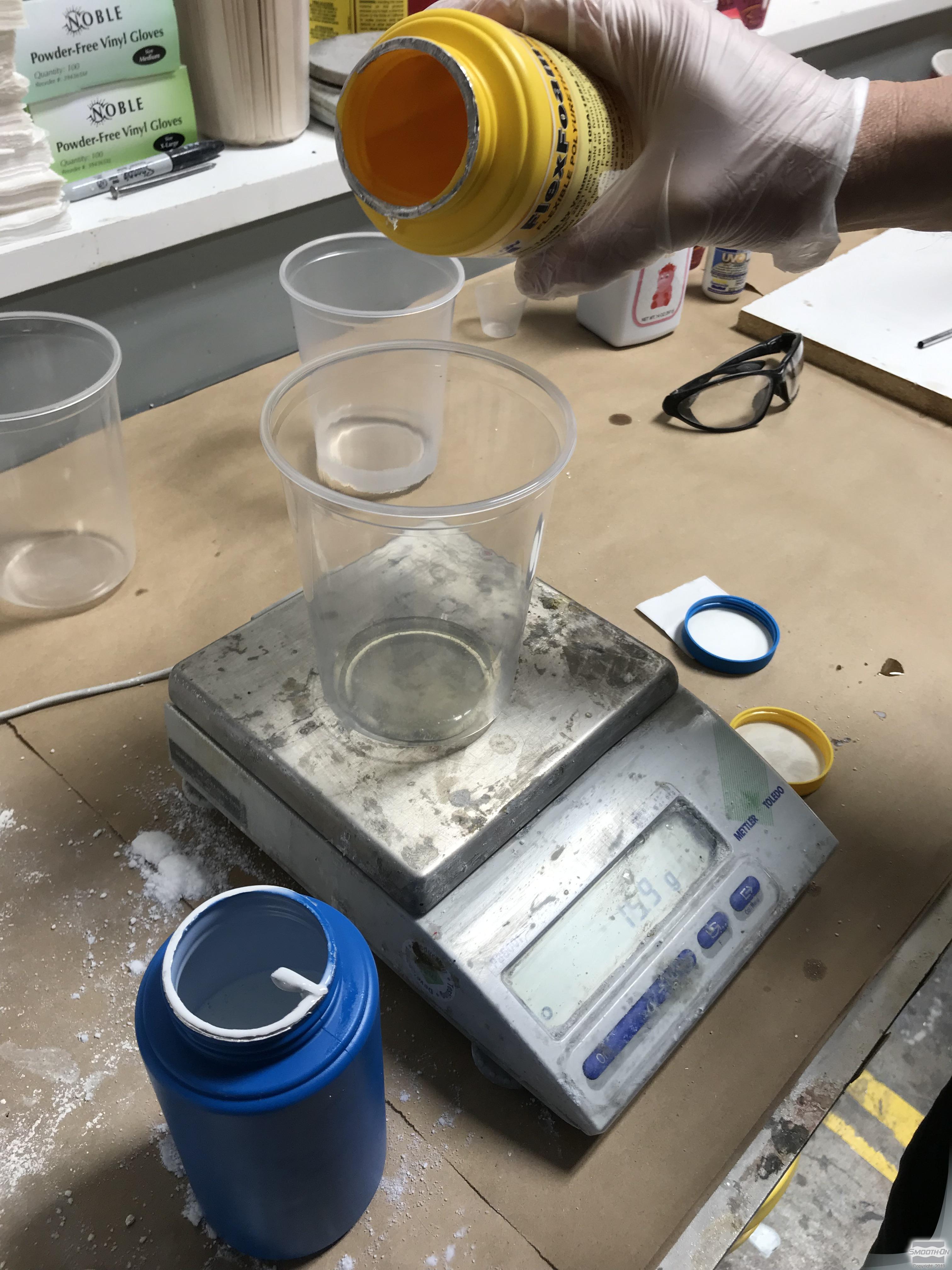

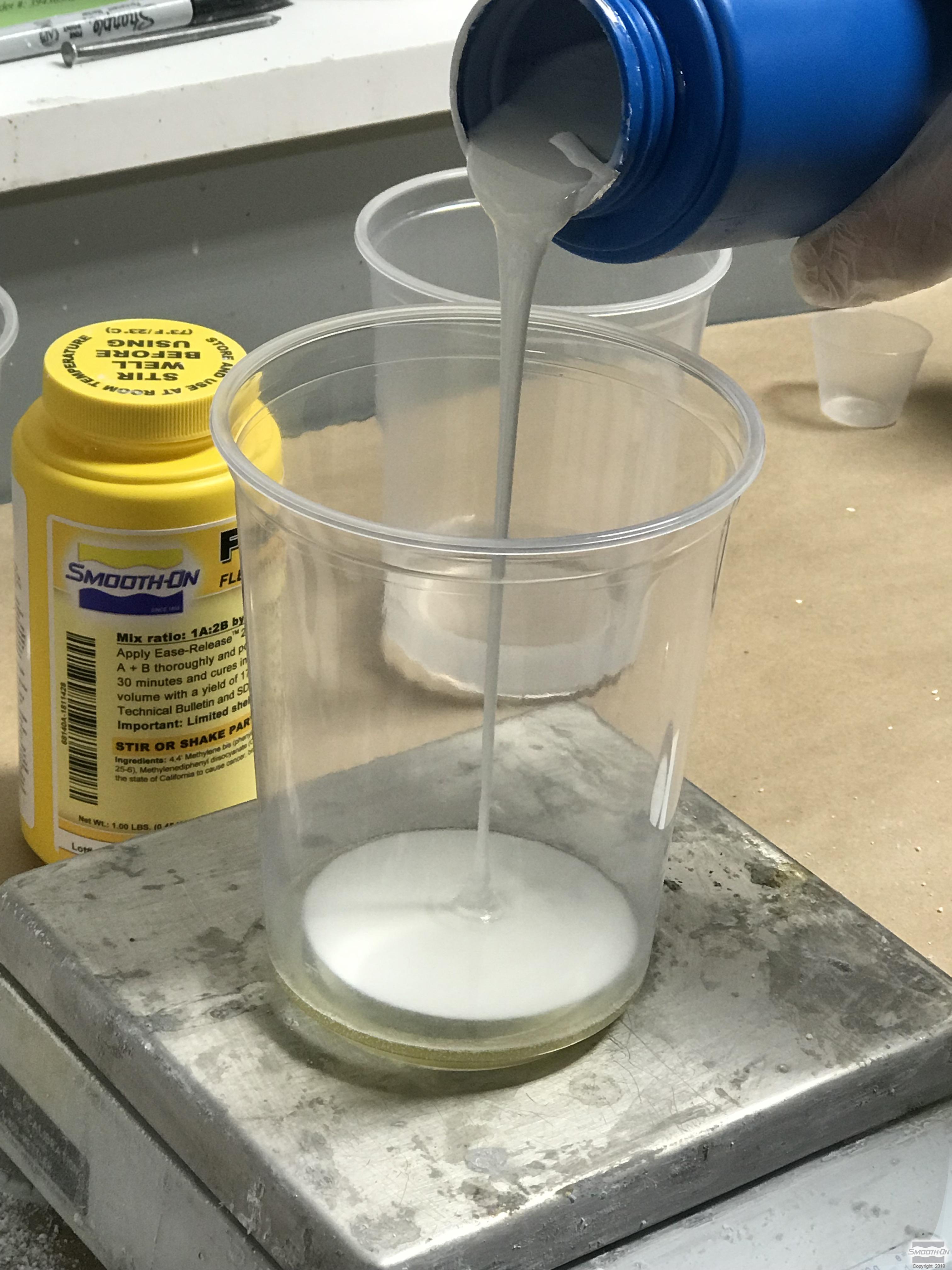

Step 2: Measure and Mix FlexFoam-iT! 15 Tuff Stuff

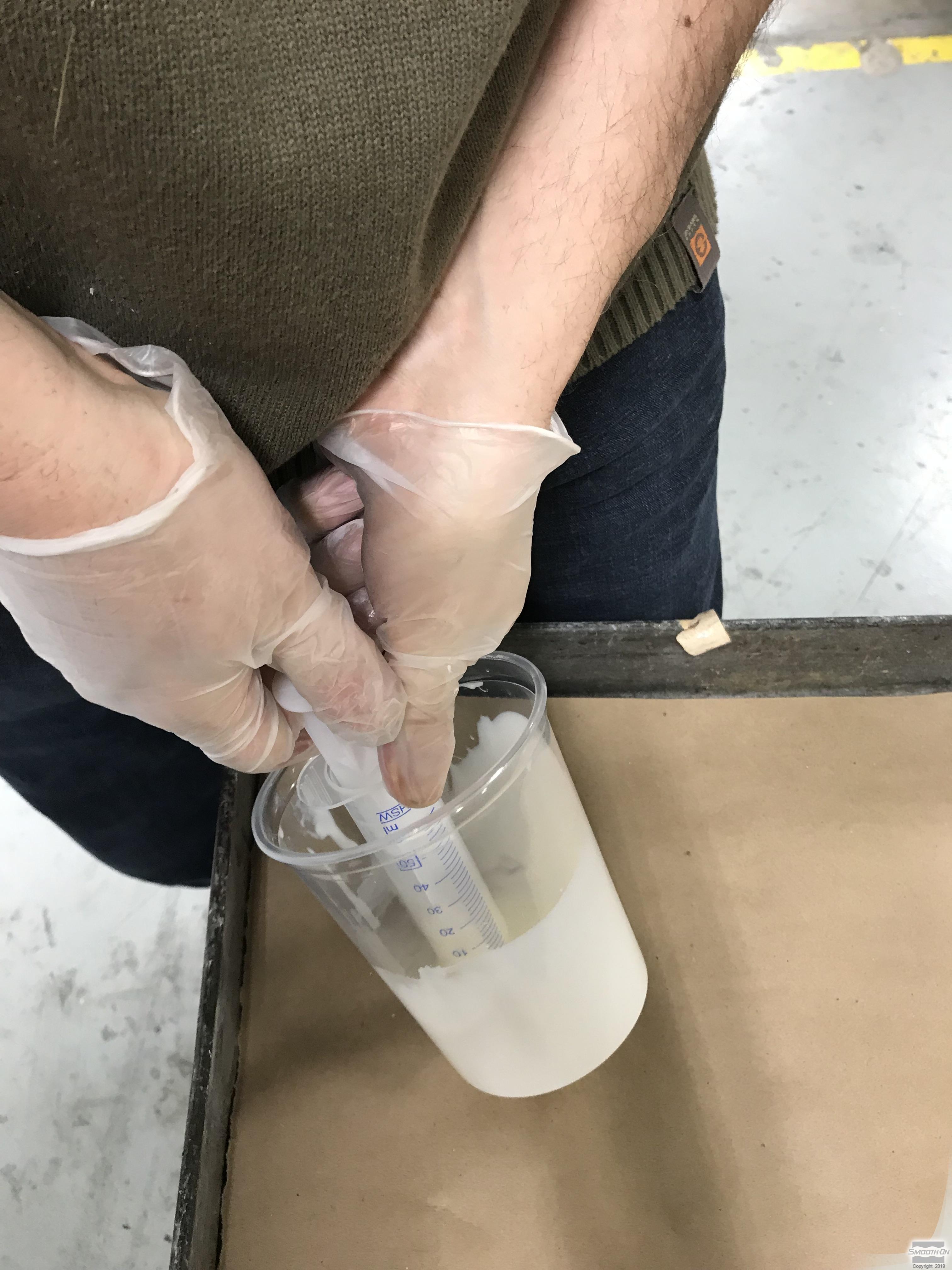

FlexFoam-iT! 15 is mixed 1A:2B by volume or 100A:185B by weight using an accurate gram scale. A small amount of material is dispensed by weight then stirred quickly and deliberately for 15 seconds, making sure to aggressively scrape the sides and bottom of the mixing container several times.

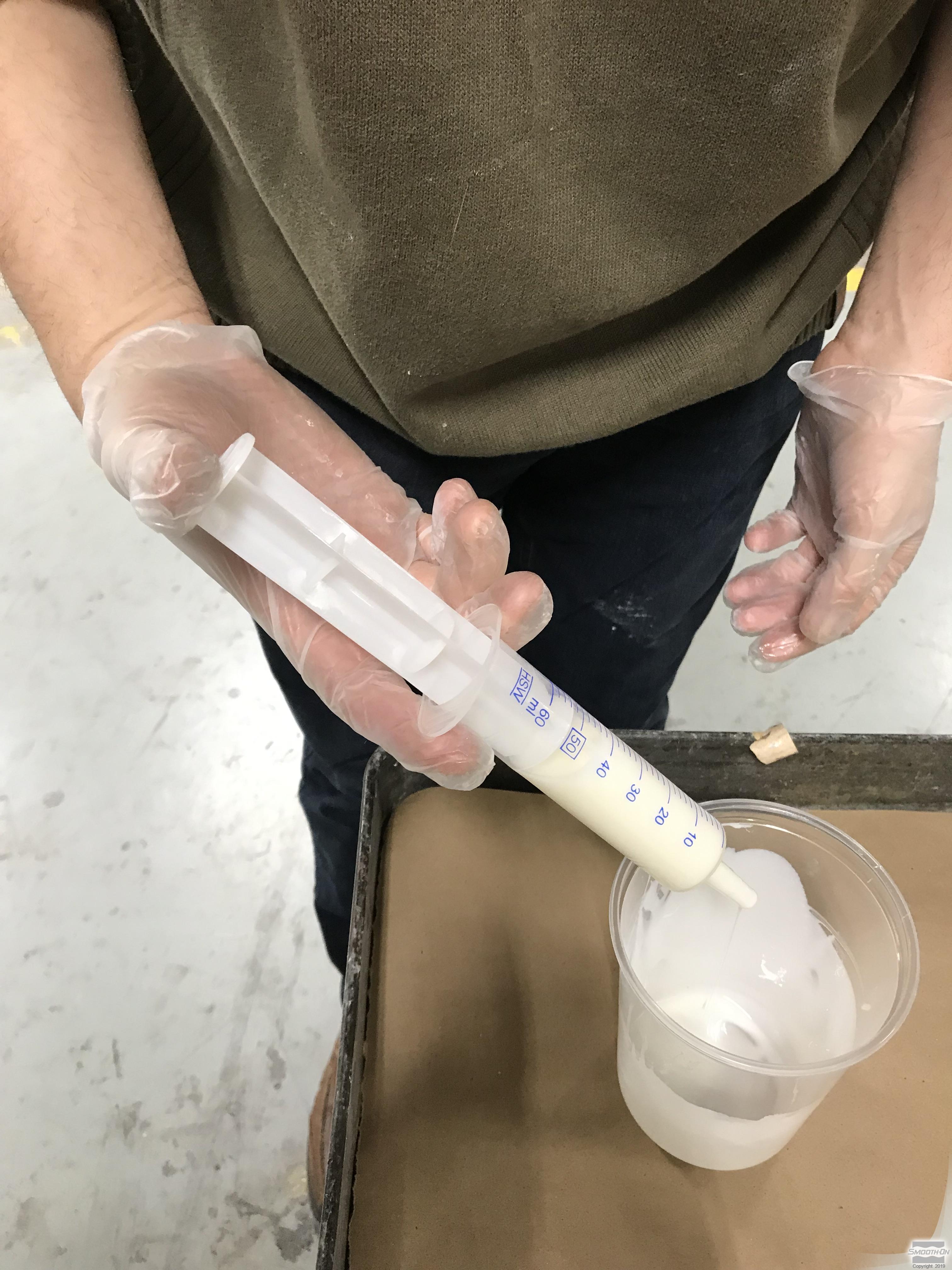

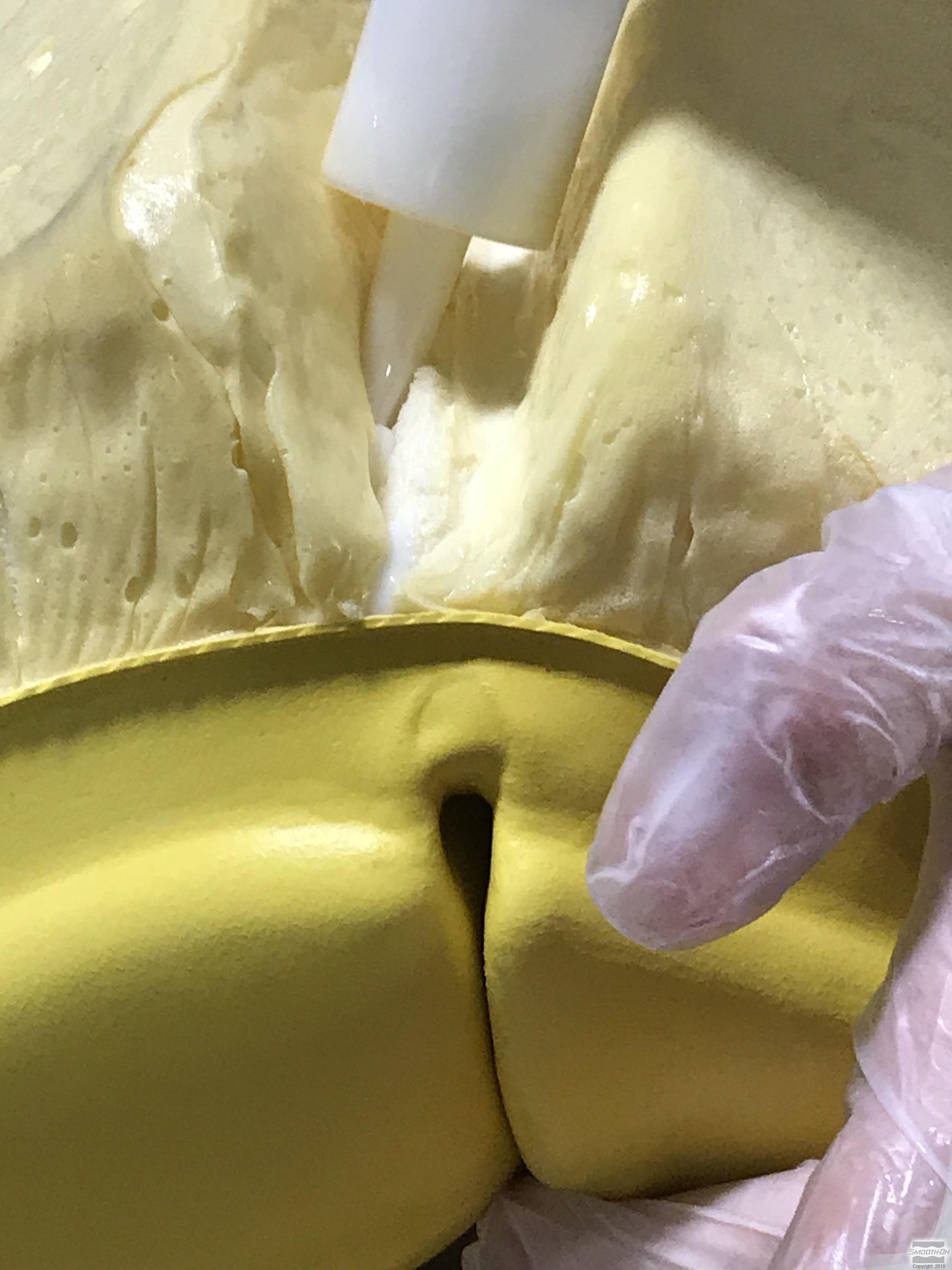

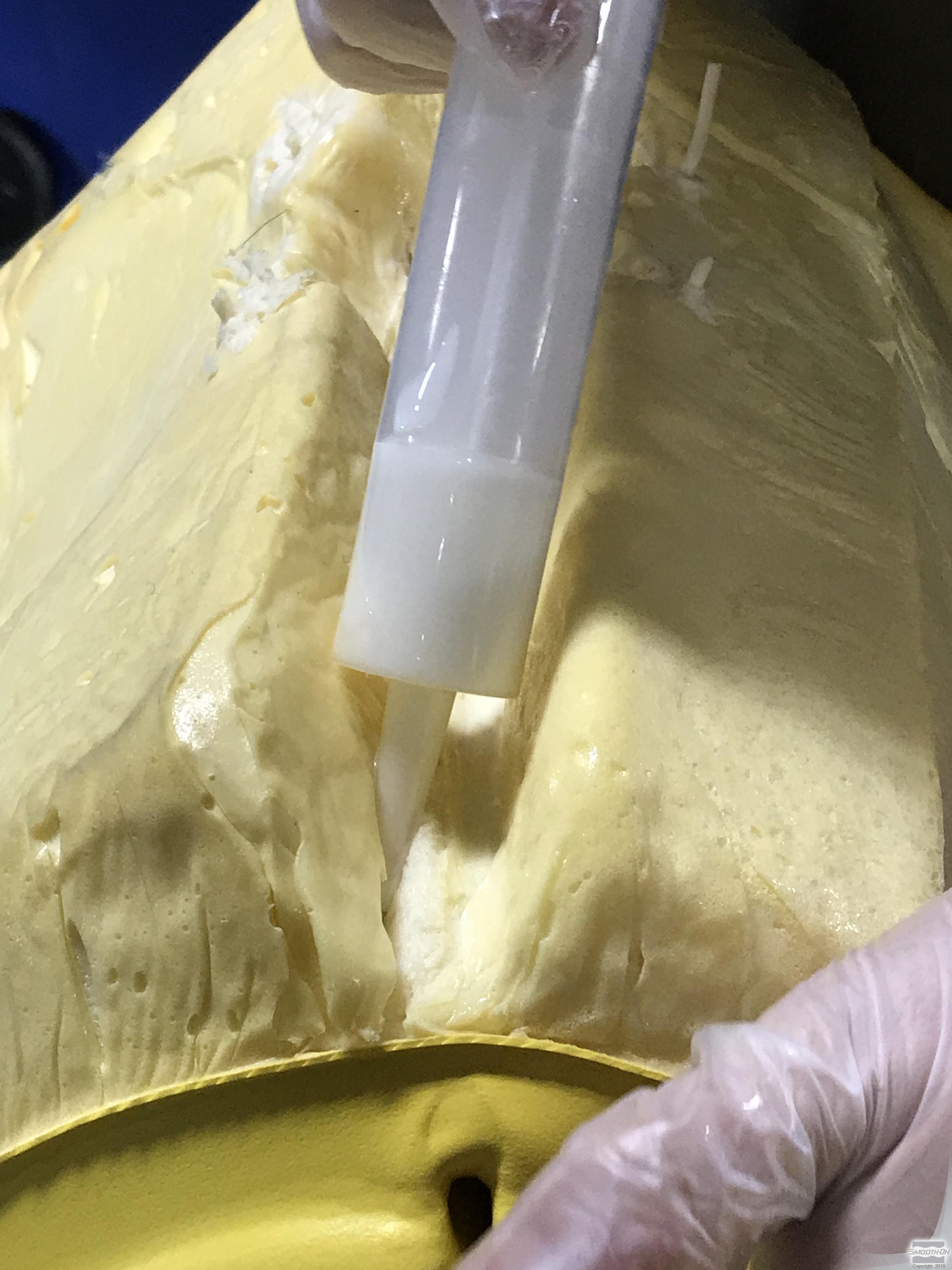

Step 3: Apply Foam to Repair

The two minute pot life allows for the liquid foam to be drawn into a plastic syringe for dispensing into the damaged area of the foam. Foam is injected at multple spot along the seam then painters' tape is used to hold the cushion together.