How To Make a Silicone Mold Using Mold Star™ 15

Overview

This instructional mold making tutorial video shows how to make a silicone block mold for casting resin, wax, foam, and many other materials using Smooth-On Mold Star™ 15 platinum silicone mold rubber.

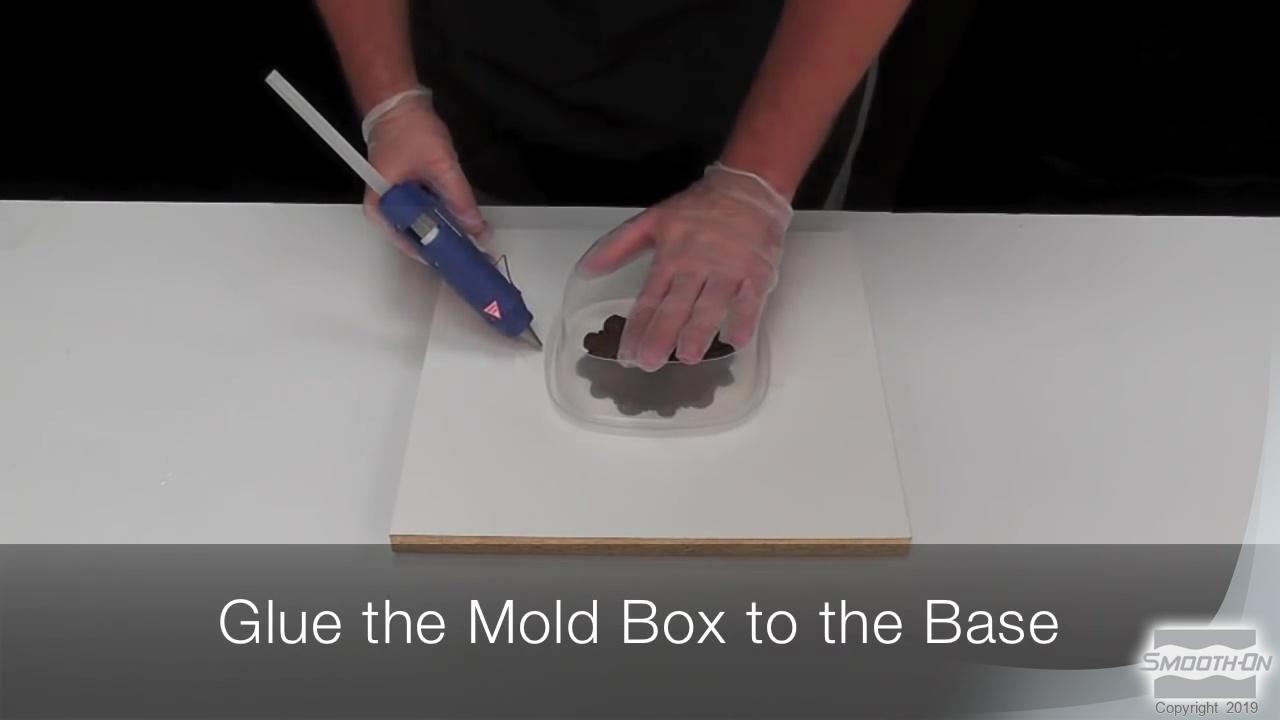

- Use hot glue to secure the model.

- Glue the mold box to the base.

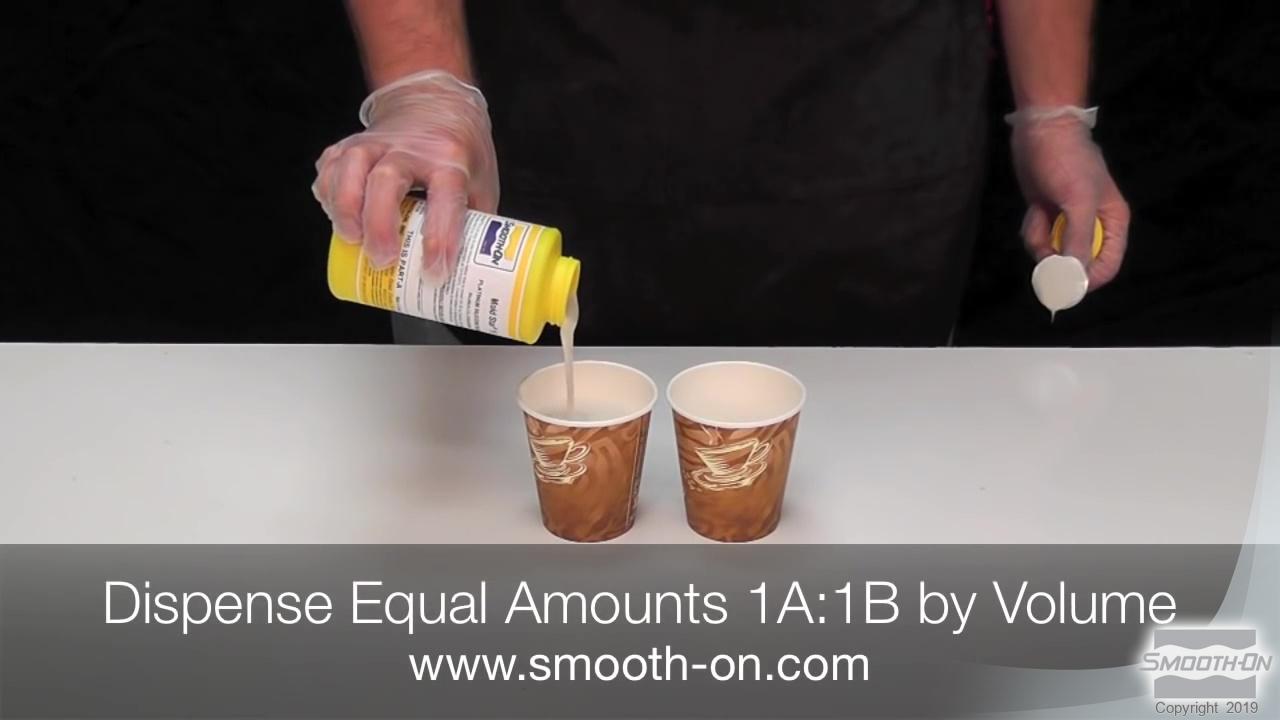

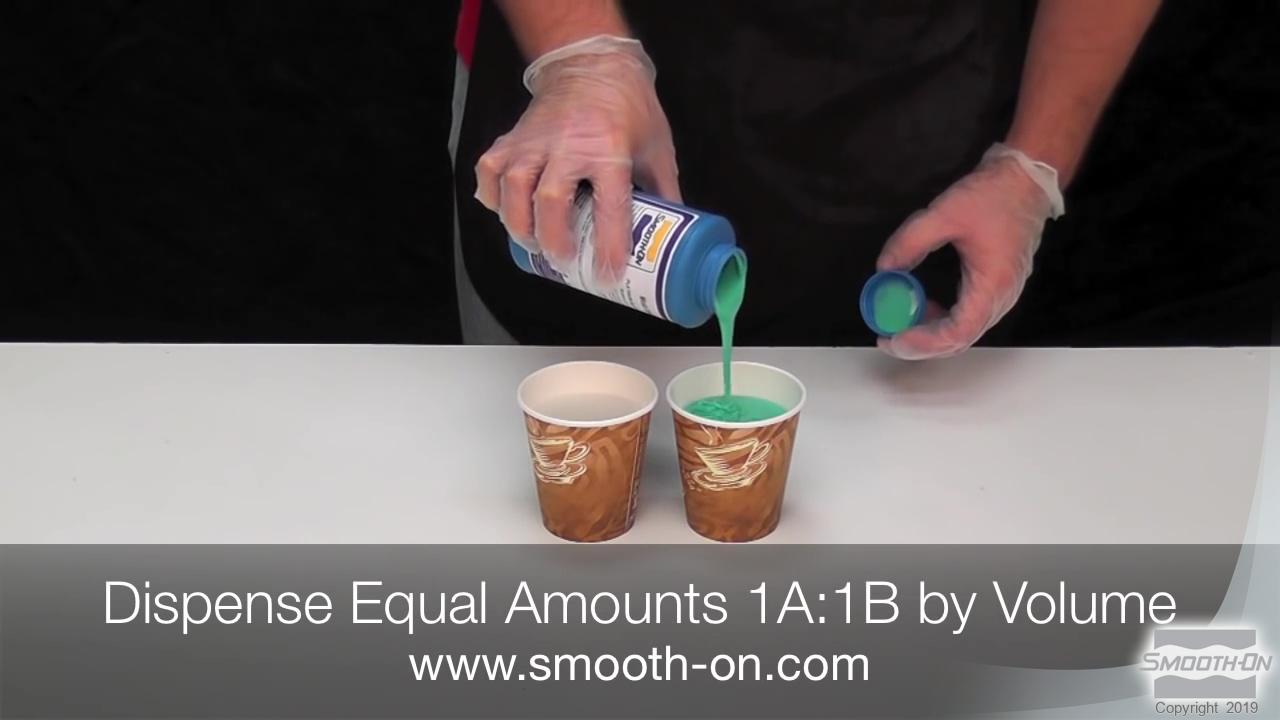

- Dispense equal amounts Parts A & B into mixing container.

- Mix Parts A & B as directed.

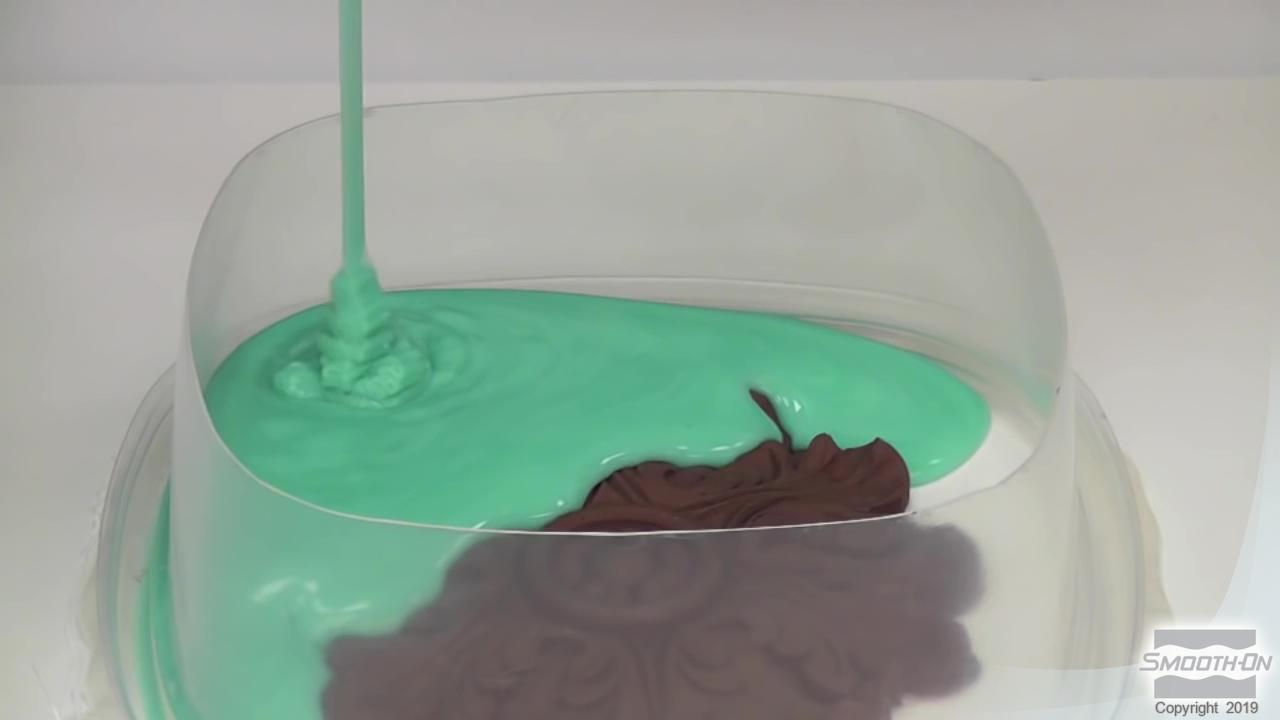

- Slowly pour into one corner of the mold box. Pour 1/2 inch (1.25cm) over model's high point.

- Allow Mold Star 15 to cure.

- Carefully remove the mold box.

- Slowly peel back the cured rubber. Mold Star™ 15 reflects perfect detail.

Mold Star™ 15 is an easy to use Shore 15A platinum silicone that is mixed 1A:1B by volume (no weighing scale necessary). It features a relatively low viscosity and vacuum degassing is not required for most applications. Pot life is an extra-long 65 minutes. Mold Star® 15 cures overnight to a soft, strong rubber that is tear resistant and exhibits very low long term shrinkage.

Step 5: Mix

Mix parts A and B as directed, carefully scraping the sides and bottom of the mixing container.