The Easiest Brushable Urethane To Mix!

Overview

EZ~Mix™ 40 Brushable Urethane Rubber: The Easiest To Mix Off All 'Off-The-Shelf' Brush-On Systems

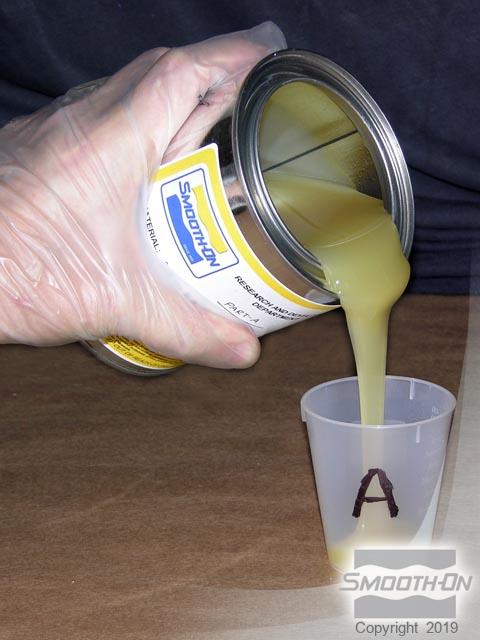

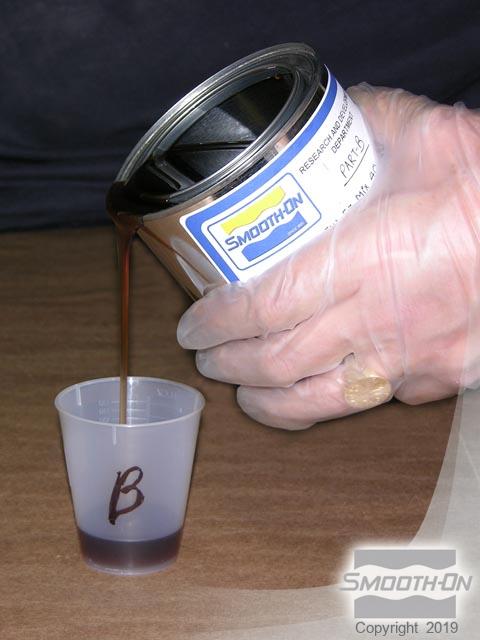

EZ~Mix™ 40 brushable urethane rubber is a liquid / liquid system. Parts A and B are very low in viscosity, making it easy to measure 1A:1B by volume and the easiest to mix of all brush-on systems (perfect for novice mold makers).

It has a good working time of 18 minutes (at room temperature) and a re-coat time of about 60 minutes. If you want to thicken the rubber to make a cut shim, you can use Cab-O-Sil or similar fillers.

Unlike Rebound™ 25, you can apply EZ~Mix™ 40 to a sulfur clay model (model must be sealed with Spray Shellac, followed by a release agent).

Beware of "mass" with this product - Unlike the other brushable rubbers, this product has a slight exotherm to it and is mass sensitive. That means that large amounts in a mixing container will gel more quickly. Also, the working time for this product will be drastically reduced in warm environments.

EZ~Mix™ 40's tear strength is better than competitive products on the market. But like these competitive products, cured rubber will "unzip" if a notch tear develops in the rubber. Brush-On™ 40, 50 and 60 have much better overall tear strength.

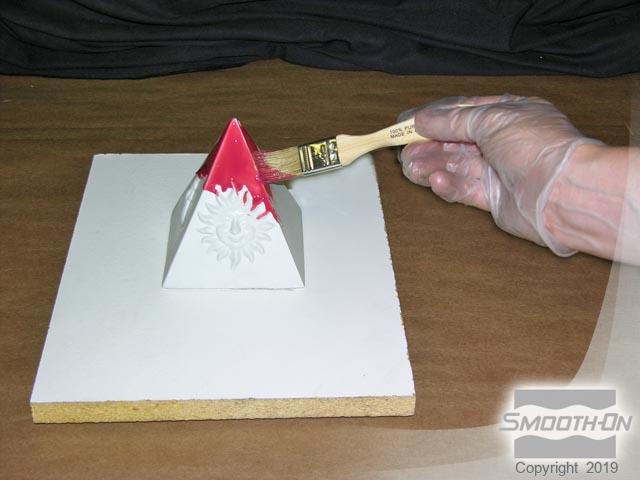

The secret for success in using this or any brush-on rubber is to apply a thin first layer (detail coat) to minimize air entrapment and capture all detail from the model's surface.

Materials Used in this Tutorial

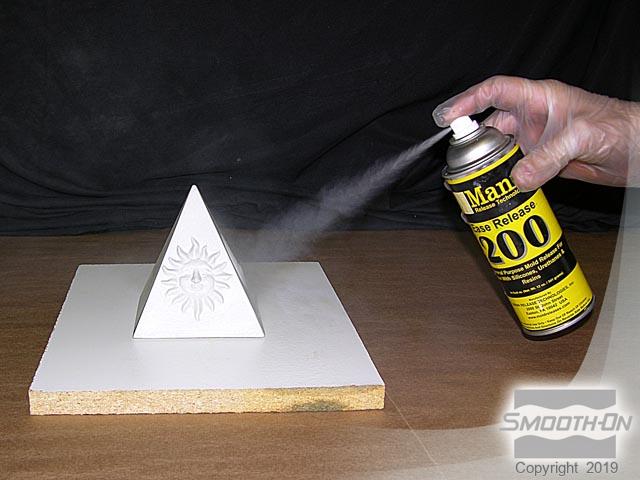

- Ease Release 200

- EZ~ Mix 40

- So-Strong Colorants

- Ure-Fil 9

- Aluminum Foil

- Plasti-Paste

- Sulfur Free Clay

- Sonite Wax

- Smooth-Cast 300

- Mixing Sticks

- Mixing Containers

- Paint Brush

Step 1: Preparing Model and Applying First 2 Layers of EZ~ Mix 40

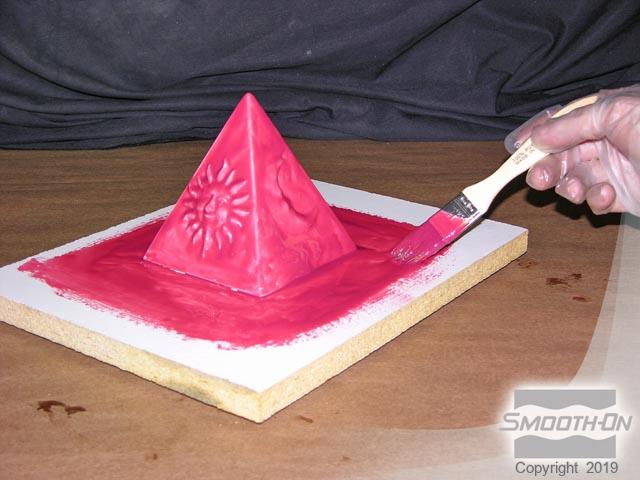

The original model is made of urethane plastic. Begin by hot gluing the original model to a working surface. Spray both the model and board with a coating of Ease Release® 200 release agent. Measure EZ ~ Mix® 40 Parts A and B in equal amounts by volume and combine in a mixing cup. (It is recommended that you wear rubber gloves during this proces.) Add So-Strong Red color tint to the rubber, which will help to ensure thorough coverage is achieved over the white model. Begin brushing the EZ~Mix® 40 onto the top of the model and work your way down. Apply the first layer thinly to ensure that all detail is captured. Create a 3 in (7.6 cm) flange. After 1 hour when the rubber is tacky, mix and apply a second untinted batch of rubber.

Step 2: Applying Thickened Layers of EZ~Mix 40

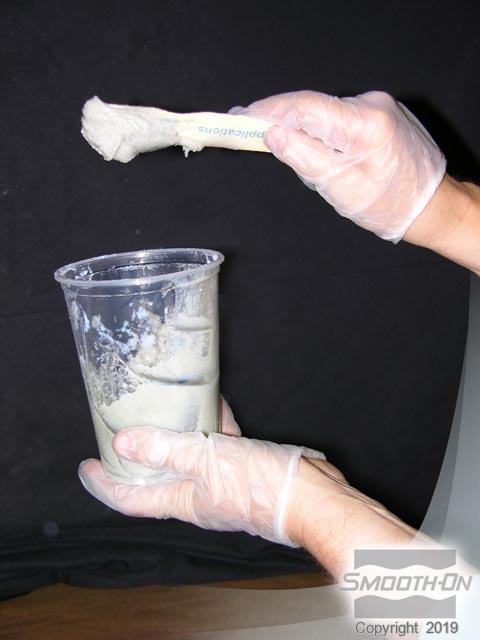

After the 2nd layer is tacky, mix Parts A and B with Ure-Fil 9 to thicken the rubber. The thickened rubber can be used to create a 'cut shim' and fill in undercuts. Add So-Strong color tint to provide contrast to the cut seam, which is applied along an edge to minimize any seam that may be reflected in finished castings. Extend the cut shim to the outer edge of the flange. Mix another batch of Ure-Fil 9 and rubber and use to further build up the cut shim.

Step 3: Applying Final Layer of EZ~Mix

A 4th (final coat) of untinted EZ~Mix® 40 is applied. All layers are then allowed to cure for at least 16 hours.

After the rubber is fully cured, the flange is trimmed to help the mold register with the support shell.

Step 4: Preparing and Applying Plasti-Paste

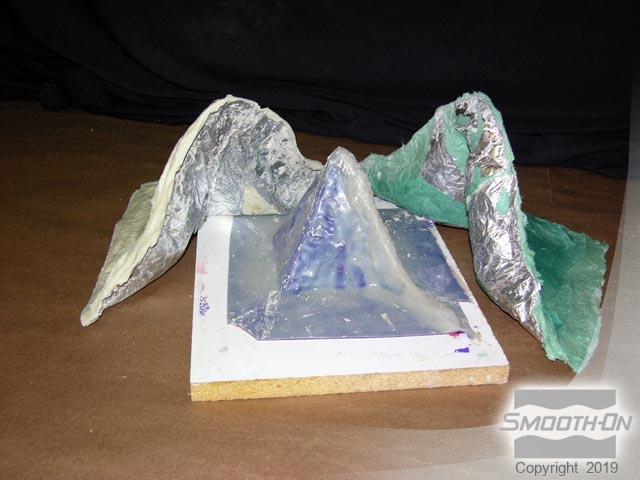

Use clay to form the parting shim, dividing the support shell into two halves. Place aluminum foil over the mold and clay shim to the Plasti-Paste® shell won’t adhere. Mix Plasti-Paste® plastic and apply it over the first half of the model, allowing the first half of the shell to cure for 90 minutes. After the first half of the shell is cured, remove the clay shim. Now, use foil to cover the second half of the rubber mold and cured Plasti-Paste® to prevent adhesion. Mix Plasti-Paste® with green pigment added and apply to the second half of the shell. Once the second half of the shell has cured, remove both halves from the rubber mold.

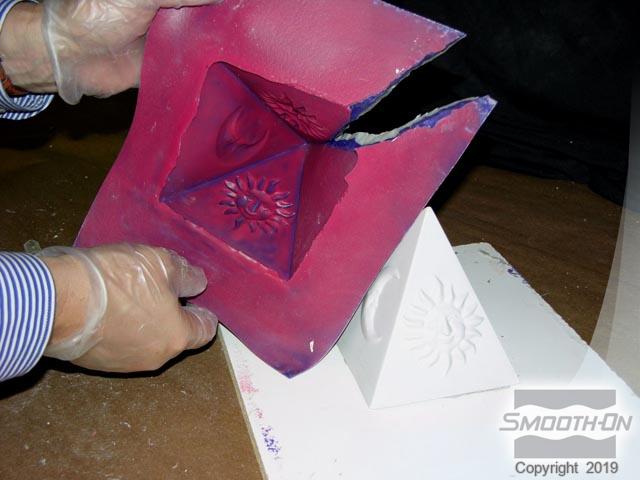

Step 5: Demolding Rubber and Casting Plastic

Use an exacto knife to cut through the thickened shim for easy removal of the rubber. The EZ~Mix® 40 mold rubber has perfectly captured all detail from the model. Reassemble the support shell and mold and place them into a bucket for stability during casting. Make sure everything is level. EZ~Mix® 40 is a urethane rubber and requires a release agent to stop the plastic from sticking, so now pour tinted Smooth-Cast® 300 into the mold.

The plastic cures quickly: demold in 15 minutes. The result is a perfect reproduction, with a mold and support shell that can be used repeatedly.