SO-Strong™

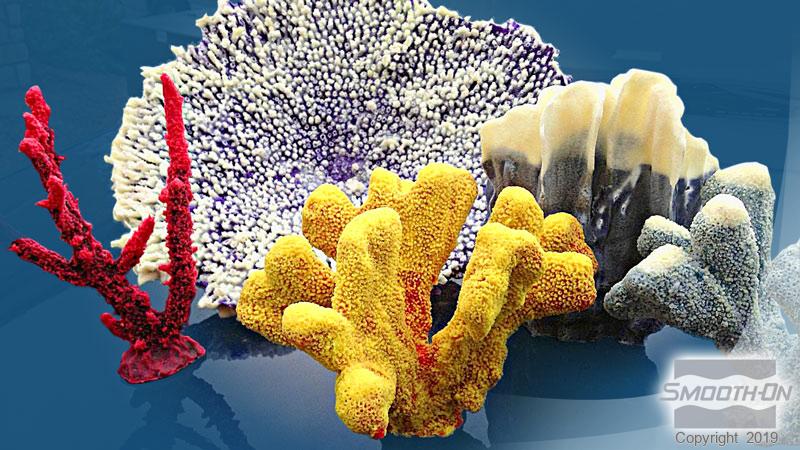

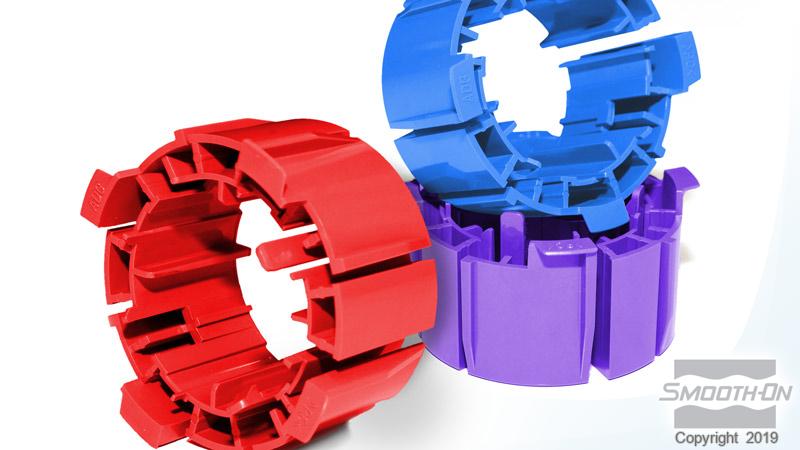

SO-Strong™ liquid urethane colorants can be added to any Smooth-On liquid urethane rubber, urethane plastic or urethane foam (do not use with Smooth-On silicones). They can be used to create a variety of color effects for a wide range of material applications. For glowing fluorescent color effects, use Ignite™ colorants.

Features

SO-Strong™ colorants are highly concentrated, offer excellent dispersion and consistent color. A very small amount will color a proportionally large amount of liquid urethane material. The more you add in proportion to the volume of liquid urethane, the more dramatic the color effect. Recommended loading range is .01% to 3% of total system weight. Do not overload the liquid urethane system or cure inhibition / oozing may occur.

User determines amount to add; If this is your first time adding color tint or pigment to a urethane system, you may want to test the color effect by adding a few drops to a small amount of urethane material and observe the outcome. It may take a few test castings to attain the desired color outcome.

Color Tints: Black, Yellow, Brown, Purple, Green, Orange, Red and Blue.

Color Pigments: White, Light Flesh, Medium Flesh, Dark Flesh

- SO-Strong™ 9 Pack Sampler includes: BLUE, BLACK, BROWN, LIGHT FLESH, GREEN, PURPLE, RED, WHITE, YELLOW.

- SO-Strong™ 8 Pack Sampler of 2 ounce bottles includes: BLUE, BLACK, BROWN, GREEN, ORANGE, PURPLE, RED, YELLOW.

Instructions

To get you started, we offer the following colorant loading levels. Results may vary.

By Weight Using A Gram Scale: Add SO-Strong™colorant at a ratio of between 0.01% - 3% of the total weight (Parts A + B mixed) of the material being cast. Adding more than 3% by weight may cause cure inhibition.

By Volume Measured In Drops: Add 10 drops of SO Strong™ per 3 oz (88 ml) of mixed urethane material. If using a translucent material (like Smooth-Cast™ 325) you can use 1 drop to maintain translucency of the material.

Directions For Use: Store and use at 73°F / 23°C. Wear vinyl gloves to prevent skin contact. After dispensing the required amount of urethane material Parts A and B into measuring containers, add colorant to Part B and mix thoroughly. Combine Parts A and B into a mixing container and mix as directed by the urethane product technical bulletin.

Blending Colors: Combine different colors on a palette to create a custom color before adding to material as directed above.

The Pantone Color Matching System is most commonly used in the printing industry to communicate color. As it relates to Smooth-On color tints and pigments, the represented color is an approximation and people’s interpretation of these colors may vary. The user will determine suitability of a color or combination of colors for the rubber, resin, foam or other product used specifically for their application. Due to the variability in products that are being colored, application, color concentration and other factors, Smooth-On makes no warranty with regards to the color.

Related Categories: Urethane Rubber, Urethane Resins, Urethane Expanding Foams, Epoxy and Urethane Coatings, Colorants, Paints & Fillers

Related Series: SO-Strong™ – Color Tints for Urethane, Urethane Rubber Accessories – Take Your Urethane Rubber Further, Urethane Resin Accessories – Take Your Urethane Resin Further, Expanding Foam Accessories

How-To Articles

UVO™ and So-Strong™ Comparison

How a casting made with UVO™ pigment and an equal amount of So-Strong™ compare