Maker Pro Paint™

Questions? Try the NEW Maker Pro Paint™ Wizard! Click Here

Maker Pro Paints™ are industrial-grade, professional paints developed for rigorous themed environment applications at amusement parks, zoos, aquariums, etc., where outdoor durability is critical. They are also suitable for various indoor rigid and flexible surface painting application projects - such as model prototyping and costuming.

Maker Pro Paints™ are Low VOC, water-based acrylic-urethanes that deliver superior color, adhesion, and durability performance. These paints are UV/fade resistant (light-fast), highly resistant to abrasions/scratches, and will withstand severe weather conditions. Maker Pro Paints™ are also “public space” safe and certify to the ASTM E-84, Class A fire rating.

When used with the Adhesion Promoter, Maker Pro Paints™ will bond tenaciously to various rigid substrates – including: rigid urethanes, rigid urethane foams, epoxy plastics, wood, fiberglass, aluminum, concrete, plasters, steel, and more. When mixed with the FLEX Additive, Maker Pro Paints™ will become more elastic and bond to flexible or semi-rigid substrates including fabrics, semi-rigid urethane resins, flexible urethane foams, urethane rubbers, and latex rubbers.

There are 18 Standard Maker Pro Paint™ Colors that mix easily for color matching. Their high pigment content formula allows for uniform coverage with fewer coatings and less paint build-up. Maker Pro Paint™ can be applied by brush, roller, airbrush, spray gun, or touch-up gun.

Maker Pro Paint REDUCER™ is a clear, water-based diluent used for thinning paint for various application methods including: spray gunning, air-brushing, rolling, brushing, etc. It is a popular choice among professional painters working in leading theme design & paint shops around the world.

› Click here for more Maker Pro Paint™ products.

Instructions

STORAGE & USAGE GUIDELINES – ENVIRONMENT: TEMPERATURE & HUMIDITY

- For best results, store and use Maker Pro Paints™ at room temperature: 73°F (23°C).

- Avoid painting in temperatures below 60°F (16°C) or above 85°F (29°C).

- Store and use at 73°F / 23°C. Do not allow Maker Pro Paint™ to freeze.

- Avoid painting in relative humidity levels above 65%.

- Close all containers tightly when not in use.

ENVIRONMENTAL EFFECTS ON DRYING PAINT:

- Within the temperature range of 65°F (18°C) to 85°F (29°C) and 65% relative humidity, Maker Pro Paint™ will dry to a matte coat in about 10 – 15 minutes. Colder temperatures will prolong drying time, while warmer temperatures will reduce drying time.

- When painting in humid conditions or temperatures lower than 65°F (18°C), make sure each coat of paint has dried “tack-free” before applying another coat.

- To reduce drying times, use a motorized fan to keep air moving above and across painted surface. Avoid pointing fans directly at wet/fresh paint.

PAINT PROJECT PLANNING & PREPARATION:

BEST PRACTICE: CONDUCT A SMALL-SCALE TEST

Before using large amounts of paint and/or covering your subject matter, always conduct a small-scale test to ensure your paint & process yields desired color and effect(s) on project substrates.

STEP 1: EVALUATE SURFACE AREA COVERAGE / PAINT VOLUME (“HOW MUCH PAINT DO I NEED?”)

- 1 Pint of Maker Pro Paint™ covers approx. 43 sq ft (4 sq meters) at 1.5 - 2 mils dry film thickness per coat (2-3 coats recommended).

- 1 Gallon of Maker Pro Paint™ covers approx. 350 sq ft (33 sq meters) at 1.5 - 2 mils dry film thickness per coat (2-3 coats recommended).

- 1 Gallon of Maker Pro Paint™ Adhesion Promoter covers approx. 600 sq ft (56 sq meters) at 1.2 - 1.5 mils dry film (only 1 thin coat needed).

NOTE: Surface area coverage varies slightly per color. Coverage will also vary depending on substrate type and texture.

STEP 2: CHOOSE YOUR PAINTING EQUIPMENT & APPLICATION METHOD:

- Brush: use brushes made for water-based paints (nylon bristle brushes, synthetic bristle brushes, or foam brushes)

- Roller: use a synthetic or microfiber roller. Keep a wet edge on painted surface for best coats/performance

Spray Equipment:

- Airbrush: use size 0.3mm - 0.5mm nozzle tip, & spray at manufacturer’s recommendations, generally ~ 25 – 35+ psi

- Touch-Up Gun: use size 1.2mm nozzle tip, & spray at manufacturer’s recommendations, generally ~ 22 – 24 psi

- Spray Gun: use size 1.2mm – 1.4mm nozzle tip, & spray at manufacturer’s recommendations, generally ~ 22 – 24 psi

STEP 3: SURFACE PREPARATION

FOR ALL SURFACES: All surfaces to be painted must be entirely free of dust, dirt, oil, grease, and other contaminants. Remove all loose chalking or flaking paint from the surface. Clean using isopropyl alcohol.

FOR PAINTING RIGID SUBSTRATES & SURFACES:

- Sand the surface to be painted with 320-grit sandpaper or a coarse scuff pad. Dry sand only. After sanding, clean surfaces using isopropyl alcohol and allow substrate to air dry completely.

- Apply one thin coat of Maker Pro Paint™ Adhesion Promoter and let air dry for 30 minutes to a uniform sheen before applying paint.

FOR PAINTING FLEXIBLE SUBSTRATES & SURFACES: (Note: Sanding Not Required)

Painting flexible surfaces (like fabrics, urethane/latex rubbers, or flexible foams) requires the paint to “flex” with the substrate.

Mix FLEX Additive with Maker Pro Paint™ in a mix ratio of 1:1 by volume to make the paint:

- bond to flexible surfaces

- more elastic

- highly resistant to cracking and peeling - even when the painted object is subject to bending, pulling, twisting, etc.

BEST PRACTICE:

Always mix FLEX Additive and Maker Pro Paint™ thoroughly to a uniform consistency using a flat edge paint stirrer.

NOTE: FLEX Additive is translucent white and will have no effect on final color once the paint dries.

IMPORTANT:

- Do not use Adhesion Promoter when painting flexible surfaces.

- Do not use FLEX Additive when painting rigid surfaces.

STEP 4: PREPARE YOUR PAINT

Pre-Mix: Thoroughly stir and mix Maker Pro Paint™ each time before use.

Adding FLEX Additive: For Painting Flexible Substrates: Mix FLEX Additive with Maker Pro Paint™ in 1:1 Mix Ratio (instructions above).

Thinning Paint (Optional):

- Thinning Maker Pro Paint™ is generally not required for brush-on or roller application.

- If thinning is required, thin with distilled water.

- For Painting Flexible Substrates & Surfaces: Mix Flex Additive with Maker Pro Paint™ in Mix Ratio of 1:1 by volume BEFORE thinning with distilled water.

Recommendations for Thinning With Distilled Water:

- Add distilled water slowly– adding & mixing in small increments (no more than 5% of total paint volume) at a time.

- For application with airbrush: thin paint with about 25% - 50% of total paint volume.

- For application with touch-up gun or spray gun: thin paint with about 10% - 20% of total paint volume.

- For all spray applications: Use distilled water to thin paint as needed to achieve finely atomized spray.

INSTRUCTIONS FOR APPLYING MAKER PRO PAINT™

- Generally, 2-3 coats of Maker Pro Paint™ are required for complete coverage of most substrates/surfaces.

- Maker Pro Paint™ will dry to a matte coat in about 10 – 15 minutes at around room temperature.

- Plan the timing of each paint coat accordingly.

- Apply Maker Pro Paint™ in thin coats (approx. 2 mils wet).

- Let each paint coat dry tack-free before applying the next coat.

DRYING

- Do not cure/dry Maker Pro Paint™ with heat or a heat gun – doing so will cause a loss of adhesion.

- Optional: use a motorized fan positioned above painted surfaces to reduce drying time. Avoid pointing fans directly at wet/fresh paint.

- Allow for extended drying times when painting in humid conditions or temperatures lower than 65°F (18°C).

- After the final coat of paint is applied, let all coats dry for 48 hours at room temperature for best performance / maximum strength and scratch resistance.

- Maker Pro Paint™ dries to vibrant colors. Any “milky haze” appearance of wet paint will dry clear.

AIRBRUSH, TOUCH-UP GUN, AND SPRAY GUN – APPLICATION INSTRUCTIONS

- We recommend applying 1 tack coat (medium) and at least 2 medium-wet coats .

- Apply 3 coats total using a 50/50 overlapping pattern for pinhole-free coverage.

- Allow each coat of Maker Pro Paint™ to air dry to a matte finish before applying subsequent coats.

- Avoid “dry spraying” - i.e. spraying at too high of a psi or spraying too far away from surface (this may create adhesion failure).

- Optimum spray distance is 6” - 8” between tip and surface.

- Paint with spray gun using a gradual motion - aiming to achieve an even distribution of paint.

- Allow a 1 hour cure time minimum if top-coating.

APPLYING A CLEAR TOPCOAT

- Maker Pro Paint™ may be top-coated with a wide variety of clear top coatings - including: water-based, solvent-based, catalyzed (2k), urethanes, and clear epoxies.

- Prior to adding a topcoat to your painted project, always conduct a small-scale test when first trying to combine a new paint and new clear coat material together. For best results, ensure your paint has dried moisture-free.

- Only apply your top coating material to paint that has completely dried.

CLEAN-UP: Use water to clean brushes and spray guns after use and to rinse in-between color changes.

Related Categories: Colorants, Paints & Fillers

Related Series: Urethane Resin Accessories – Take Your Urethane Resin Further, Expanding Foam Accessories, Flame Rated Materials – Protecting Public Spaces, Epoxy Accessories – You Can Do Even More, Maker Pro Paint™ – High Performance Paint System

How-To Articles

Painting a Flexible Foam Casting Using Maker Pro Paint™

Painting a Flexible Foam Casting Using Maker Pro Paint™

Painting Latex Rubber Using Maker Pro Paint

Learn the process of painting a latex rubber mask using Maker Pro Paint in this video

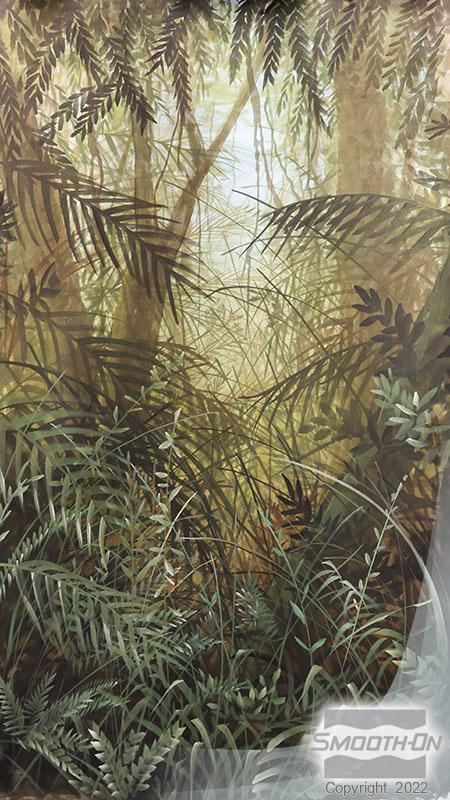

Theming a Haunted Attraction Maze at Dorney Park Amusement Park

Watch as walls are themed to look like a crumbling steel plant using Buddy Rhodes Vertical Mix and Maker Pro Paints.