How To Make a Sea Anemone Using Smooth‑On Silicone

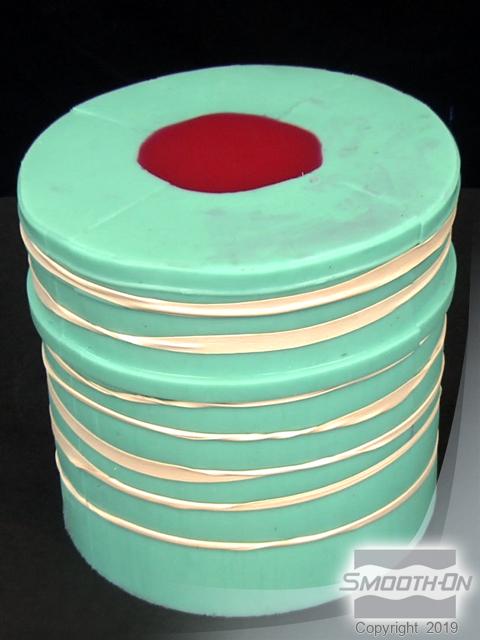

Step 5: Casting EcoFlex™ 00‑30 with Ignite™ Colorants

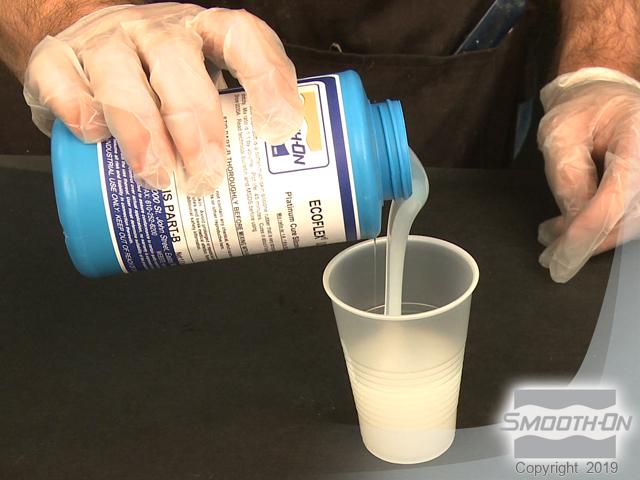

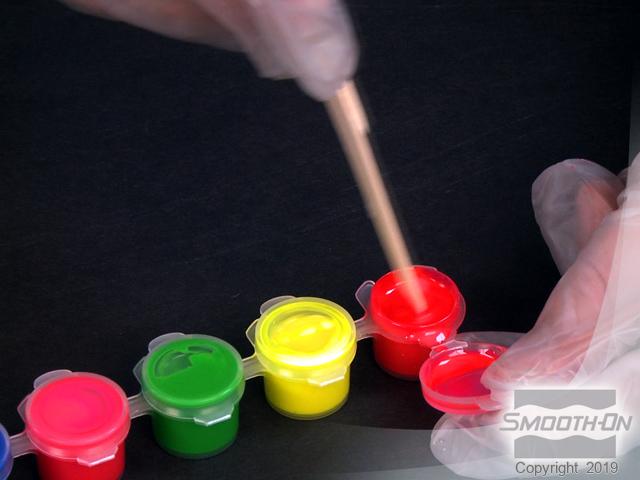

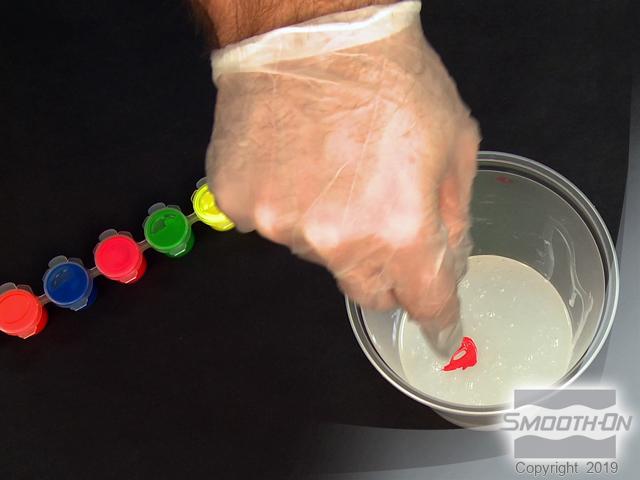

EcoFlex™ 00-30 supersoft silicone rubber will be used to make the casting. It has a mix ratio of 1 part A to 1 part B by volume. First, dispense part B and and pre-mix the Ignite™ red pigment. Then, mix the Ignite™ red into part B until there are no streaks. The pigment is concentratated so alittle goes a long way. Ignite™ fluorescent color pigments that glow under UV light are used to pigment the silicone.

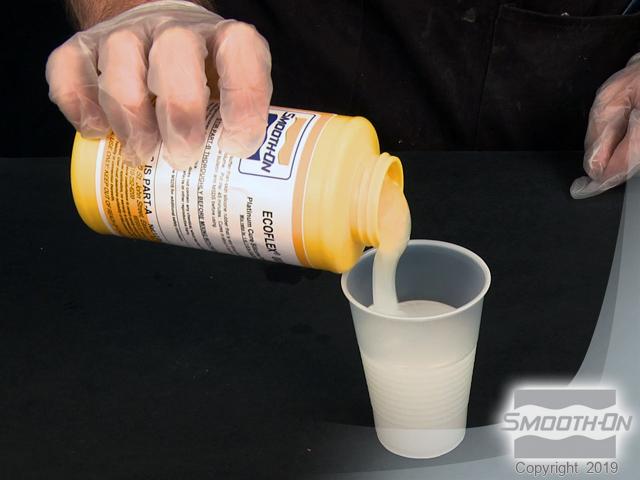

Now, dispense equal part A and pour part A into the colored part B. Thoroughly mix parts A and B together to remove all color streaks. EcoFlex™ 00-30 has a pot life of 45 minutes.

Use a vacuum chamber to vacuum out air bubbles within the silicone. The silicone will rise, break and fall. Your vacuum must pull 29 inches of mercury for complete vacuum. Then, slowly pour the vacuumed silicone into the mold cavity. Allow EcoFlex™ 00-30 to cure for at least 4 hours at room temperature (73 F).