Advanced Techniques

The next step in moldmaking. These videos and step-by-step tutorials show techniques which are for advanced users and include cavity molds, multi-part molds, and other ways to mold complicated originals.

Whether you are interested in reproducing a sculpted figure, an antique picture frame, an industrial pattern, an architectural molding, a fossil, animal skin (taxidermy), the texture of a piece of fabric, or a toy, you start by making a rubber mold. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold.

Whether your original model is made from clay, wax, plaster, sand, concrete, stone, metal, bone or almost any material, making a rubber mold makes it possible to reproduce that model – exactly.

Featured Step-by-Step How-To's

Creating an Epoxy Mold for a Silicone Makeup Prosthetic

Watch as we craft an epoxy mold for an encapsulated silicone prosthetic of a snake person makeup.

Creating a Clear, Hollow Casting Using Crystal Clear™ Urethane Resin

Milo shows how to rotocast a clear object using Crystal Clear™ 202 urethane resin

How to Make a Free-Form Concrete Sink

Watch how to make an elegant shallow free-form concrete sink from start to finish

Building the World's Largest Underwater Christmas Tree

How Vegas Props fabricated the world's largest underwater Christmas tree

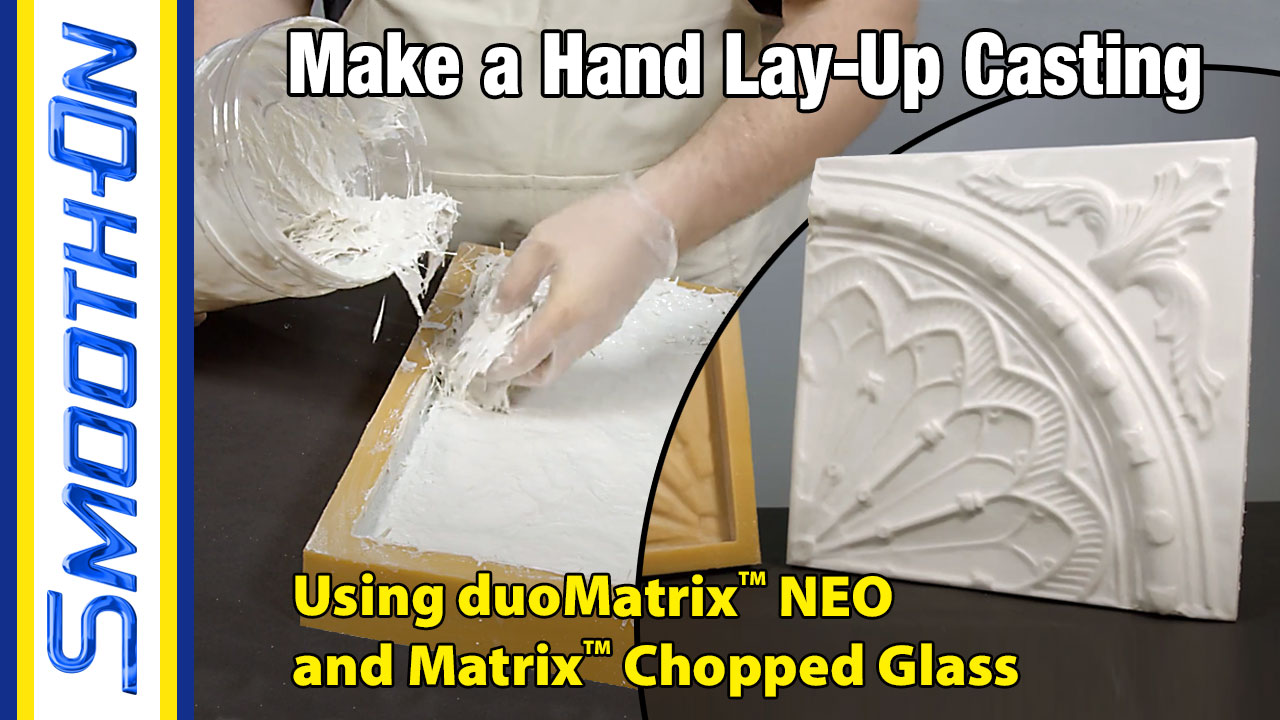

How To Make a Hand Lay Up Casting Using duoMatrix™ NEO and Matrix™ Chopped Glass

Making a durable lightweight architectural element or display piece is possible using duoMatrix NEO polymer-modified gypsum and Matrix Chopped Glass.

How To Make a Kiln Formed Glass Sign for Retail Kiosks

Learn how Greg Schadt of Gravity Glas Design created an amazing kiln-formed sign.

How To Make a Replacement Car Lens Using Crystal Clear 202

How you can replicate a tail light lens of any car using optically-clear resin.

How To Create a High Temperature Tool Using EpoxAmite™ HT and EpoxAcoat™ HT

High temperature tooling resins play an important role in creating composite parts and are a low cost alternative to metal molds.

How To Use EpoxAmite™ to Create Carbon Fiber Composite Parts

Nordan is a world renowned fabricator of performance composite parts for racing cars...

View All How-To Videos and Galleries ›

What People Have Done With These Materials

Restoring an Historic Concrete Seal at Princeton University

Watch How John Paolini, from Paolini Cast Stone, Restored an Historic Concrete Seal