VytaFlex™ Series

Liquid Urethane Rubbers

Using Smooth-On’s exclusive “V-Polymer™” technology, VytaFlex™ urethane rubbers offer superior physical and performance properties for casting concrete. VytaFlex™ mold rubbers work especially well for casting pigmented / colored concrete. Molds made with VytaFlex™ Series urethanes will render accurate and uniform colored castings.

HIGHLIGHTS

"V-Polymer™" Technology

Formulated Especially for Casting Concrete

"V-Polymer™" Technology

Formulated Especially for Casting Concrete

- Superior physical & performance properties.

- Long-term dimensional stability.

- Color-accurate castings every time.

- Consistent surface finish every time.

One to One Mix Ratio

One to One Mix Ratio

No Scale Necessary

No Scale Necessary

Low Viscosity

Low Viscosity

Lasting Durability

Real World Results

Lasting Durability

Real World Results

Concrete casting pros in the U.S. and around the world know VytaFlex™ as the industry standard for making rubber molds that have the abrasion resistance and tear strength needed to keep production moving.

Tough and Durable

Tough and Durable

Large or Small Scale

For Production Casting On Any Scale

Large or Small Scale

For Production Casting On Any Scale

Make large scale formliners with VytaFlex™ mold rubber or a library of Stone Veneer molds both proven to hold up to the rigors of casting concrete everyday.

Professional Grade

Professional Grade

Glass Fiber Reinforced Concrete

VytaFlex™ and FORTON™ Perfect Together

Glass Fiber Reinforced Concrete

VytaFlex™ and FORTON™ Perfect Together

The versatility and durability of your VytaFlex™ rubber molds will allow you to maximize the full benefits of using FORTON™ VF‑774 Acrylic Polymer in GFRC to produce custom architectural elements.

Abrasion Resistant

Abrasion Resistant

Technical and Buying Information

| Select a Product Below | Hardness | Die C Tear Strength |

|---|---|---|

| › VytaFlex™ 10 | 10 A | 38 pli |

| › VytaFlex™ 20 | 20 A | 60 pli |

| › VytaFlex™ 30 | 30 A | 78 pli |

| › VytaFlex™ 40 | 40 A | 82 pli |

| › VytaFlex™ 45 | 45 A | 100 pli |

| › VytaFlex™ 50 | 50 A | 102 pli |

| › VytaFlex™ 60 | 60 A | 136 pli |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How to Make a Free-Form Concrete Sink

Watch how to make an elegant shallow free-form concrete sink from start to finish

How To Make a Sunscreen Curtain Wall from a Digital Design

Smooth-On's client "Taller de Prefabricados" invited us to to film their process

How To Build a Concrete Bar Using GFRC Panels - Episode 1

Learn how to make Art Deco concrete panels from model design to casting pigmented GFRC.

How To Build a Concrete Bar Using GFRC Panels - Episode 2

Learn how to make an outdoor bar and pergola, using Art Deco GFRC panels.

How To Build a Concrete Bar Using GFRC Panels ‑ Episode 3

Learn how to make unique edge molds for concrete countertops using TASK 16 urethane rubber.

Taking the Mystery Out of How to Make a Concrete Sink Mold

This step-by-step guide uses Smooth-On's VytaFlex® 40 mold rubber to demonstration how to make a concrete sink mold.

How To Pre Cast Concrete Walls Created to Rebuild New Orleans

Smooth-On Materials Used As Part Of One Man's Vision To Bring Hope To Residents Of Storm-Weary New Orleans

How To Make a Custom Concrete Bench

Benchmark's recent job for Penn State University involved making a custom concrete bench. Mr. Rohn once again turned to VytaFlex for the mold rubber.

How To Cast Concrete Stone Veneer Using VytaFlex™ Mold Rubber

A brief, step-by-step gallery detailing a common casting procedure featuring Vytaflex® urethane rubber being used for casting concrete.

How To Make a Large Scale Formliners with VytaFlex™ Mold Rubber

The Pennsylvania DOT needed 2,000 decorative noise reduction panels to maximize public safety and divert highway noise.

Custom Gasket Made With VytaFlex™ Urethane Rubber

Corso Fluids, a manufacturer of industrial fluids that has been in operation for decades...

What Have Other People Done With These Products?

Caribbean Cast Stone Adds Touch of Class to Plaza In Puerto Rico

Caribbean Cast Stone, Inc. began construction on a new $10 million plaza in Rio Grande, Puerto Rico.

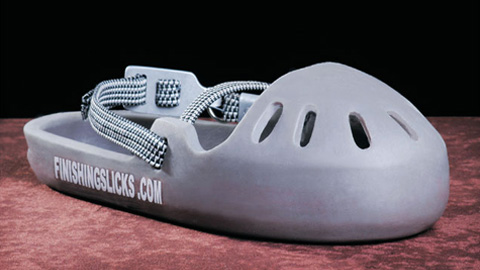

From Prototype to Reality: Concrete Finishing Slicks Success Story

After pouring thousands of tons of concrete to make a floor or platform, concrete finishers are called on to finish the concrete surface by smoothing out all surfaces.