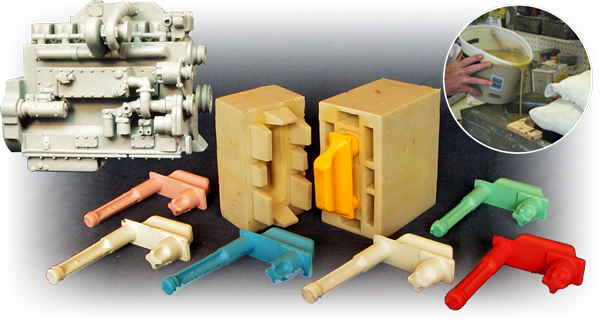

TASK™ Series

High Performance Casting Resins

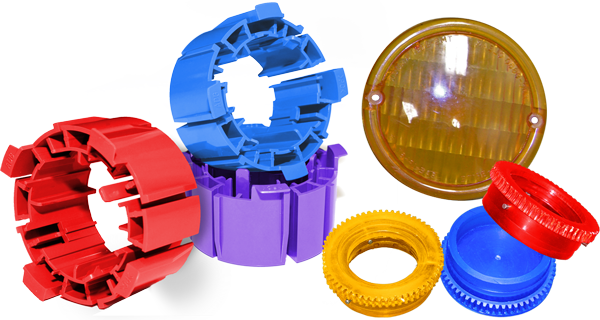

Smooth-On's specialty line of performance urethane casting resins that offer superior physical properties compared to our popular Smooth-Cast™ line of general purpose casting resins. TASK™ plastics feature convenient mix ratios by volume (pbv) or weight (pbw), low viscosities, high tensile and flexural strength, as well as high flexural modulus. Some have specific performance characteristics such as flame resistance, high temperature resistance, and very high impact resistance.

HIGHLIGHTS

TASK™ 2 and TASK™ 3

TASK™ 2 and TASK™ 3

Low viscosity, fast cure resins made especially for rapid prototyping. These plastics are bright white and were formulated as higher performing alternatives to our Smooth‑Cast™ 300 Series resins.

No Scale Necessary

No Scale Necessary

Low Viscosity

Low Viscosity

1:1 Mix by Volume

1:1 Mix by Volume

TASK™ 4

TASK™ 4

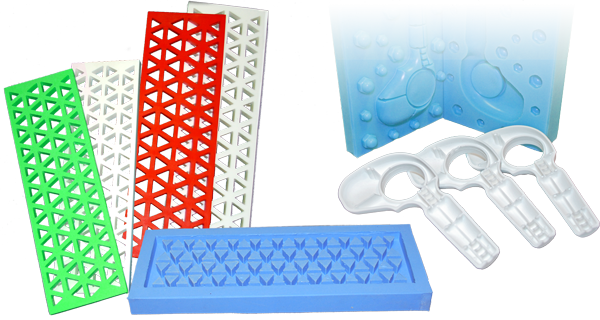

A unique casting resin that is very strong when cast in Ultra-Thin sections ranging from 0.03” to 0.50” (0.075cm to 1.27cm). TASK™ 4 exhibits very low shrinkage which is why this plastic has become a favorite of precision prototype and design professionals throughout the world.

Gram Scale Required

Gram Scale Required

Low Viscosity

Low Viscosity

Low Shrinkage

Low Shrinkage

TASK™ 5 and TASK™ 6

Lowest Cost Performance Plastics Anywhere

TASK™ 5 and TASK™ 6

Lowest Cost Performance Plastics Anywhere

Vacuum degassing is not necessary and they offer the convenience of a 1A:1B by volume. Differences between TASK™ 5 and TASK™ 6 are the pot life and demold time.

No Scale Necessary

No Scale Necessary

One to One Mix Ratio

One to One Mix Ratio

Low Viscosity

Low Viscosity

TASK™ 7 Flame Out™

Flame Rated

TASK™ 7 Flame Out™

Flame Rated

Low viscosity, fast set casting resin that meets UL 94 V‑O requirements for flame resistance. TASK™ 7 does not contain mercury, TDI or MOCA.

Flame Rating

Flame Rating

One to One Mix Ratio

One to One Mix Ratio

No Scale Necessary

No Scale Necessary

TASK™ 8

Heat Resistant Casting Resin

TASK™ 8

Heat Resistant Casting Resin

Made specifically for prototyping / casting applications which require thermal resistance of up to 263°F/129°C. Heat curing this material is necessary to attain optimal heat resistance.

No Scale Necessary

No Scale Necessary

Heat Resistant

Heat Resistant

1:1 Mix by Volume

1:1 Mix by Volume

TASK™ 9 ColorMatch

Color Match High Performance Resin

TASK™ 9 ColorMatch

Color Match High Performance Resin

Features very high compressive strength and tensile strength. TASK™ 9 is clear amber, which makes this plastic very easy to color using SO-Strong™, UVO™ or IGNITE™ colorants.

Easy to Color

Easy to Color

1:1 Mix by Volume

1:1 Mix by Volume

No Scale Necessary

No Scale Necessary

TASK™ 11

Semi-Rigid Resin - Dry Food Applications

TASK™ 11

Semi-Rigid Resin - Dry Food Applications

Semi-rigid plastic that is strong and very tough. Originally developed for high impact tooling, TASK™ 11 also offers good abrasion and chemical resistance and is ideal for a variety of industrial applications. This product is suitable for some FDA/USDA applications - dry food contact only.

Gram Scale Required

Gram Scale Required

Impact Resistant

Impact Resistant

TASK™ 12

Impact Resistant Tooling Resin

TASK™ 12

Impact Resistant Tooling Resin

Semi-rigid urethane resin that offers extraordinary handling strength and impact resistance. Used for a variety of industrial applications including making prototype models, high impact parts and tools. CAUTION: NOT FOR HOME USE. THIS PRODUCT IS FOR INDUSTRIAL USE ONLY.

Gram Scale Required

Gram Scale Required

Impact Resistant

Impact Resistant

TASK™ 13 and TASK™ 14

Semi-Rigid Black Casting Resin

TASK™ 13 and TASK™ 14

Semi-Rigid Black Casting Resin

With a Shore value of 50D, these semi-rigid plastics are used for a variety of industrial applications including fast mold making, fast model duplication, prototyping, durable miniatures, black props and special effects, or making parts that are impact resistant.

For Best Results… Do not cast TASK™ 13 or TASK™ 14 into platinum cure (addition cure) silicone molds.

Gram Scale Required

Gram Scale Required

Impact Resistant

Impact Resistant

TASK™ 15

Roto Casting, Impact Resistant Performance Resin

TASK™ 15

Roto Casting, Impact Resistant Performance Resin

Features a gradual cure profile, making it ideal for rotational casting applications (making hollow parts). TASK™ 15 exhibits very high impact strength, even when cast in thin-wall sections.

Gram Scale Required

Gram Scale Required

Impact Resistant

Impact Resistant

TASK™ 16

Tough 80A/30D Semi-Rigid Urethane

TASK™ 16

Tough 80A/30D Semi-Rigid Urethane

TASK™ 16 offers very high tear strength, impact resistance and wear resistance. Suitable for making fast mechanical parts, gaskets, wheels and pulleys, impact resistant props, and archival master models. It is also used to make fast, wear resistant rubber molds for casting concrete or concrete stamping pads.

Gram Scale Required

Gram Scale Required

Impact Resistant

Impact Resistant

High Tear Strength

High Tear Strength

TASK™ 18

Aluminum filled mass casting resin

TASK™ 18

Aluminum filled mass casting resin

Relatively low viscosity aluminum filled urethane casting resin that was developed specifically for making short run vacuum forming molds with a very high compressive and flexural strength.

Gram Scale Required

Gram Scale Required

Low Shrinkage

Low Shrinkage

TASK™ 21

TASK™ 21

A performance urethane casting resin that has been described by many as having similar performance and mechanical characteristics to ABS plastic, with high compressive and flexural strength.

For Best Results… Do not cast TASK™ 21 into platinum cure (addition cure) silicone molds.

No Scale Necessary

No Scale Necessary

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › TASK™ 2 | Low Viscosity, High Performance Casting Resin |

| › TASK™ 3 | Low Viscosity, High Performance Casting Resin |

| › TASK™ 4 | Very Strong When Cast In Ultra-Thin Sections |

| › TASK™ 5 | Lowest Cost High Performance Casting Resin |

| › TASK™ 6 | Lowest Cost High Performance Casting Resin |

| › TASK™ 7 | Flame Rated Urethane Casting Resin |

| › TASK™ 8 | High Heat Resistant Urethane Casting Resin |

| › TASK™ 9 | Color Neutral High Performance Urethane Casting Resin |

| › TASK™ 11 | Semi-Rigid Urethane Casting Compound Suitable For Dry Food Contact |

| › TASK™ 12 | Semi-Rigid Resin With Extraordinary Strength and Impact Resistance |

| › TASK™ 13 | Semi-Rigid Black Urethane Casting Resin |

| › TASK™ 14 | Semi-Rigid Black Urethane Casting Resin |

| › TASK™ 15 | Impact Resistant Performance Resin Designed For Rotocasting |

| › TASK™ 16 | Extremely Tough 80A/30D Urethane Elastomer |

| › TASK™ 18 | Aluminum Filled Urethane Resin With Very High Compressive Strength |

| › TASK™ 21 | Urethane Casting Resin With Performance Similar To ABS |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Make Concrete Countertops for a Trade Show Display

In this video we show you how we created new concrete countertops for a custom pergola display.

How To Mold and Cast a Record That Actually Plays

How moldmaking and casting expand horizons for a seminar graduate whose passion is 78 RPM records

How To Make a 2 Piece Silicone Mold to Cast a Police Baton Prop

This step-by-step tutorial shows the process of making a two-piece block mold from a police baton using Mold Max® 30 silicone rubber. It also shows how to cast a reproduction using TASK 13 semi-rigid resin.

How To Replace a Brass Shower Door Handle

A "Cold Cast Brass" handle is molded and cast for a fraction of the cost of replacement.

How To Vent a Silicone Mold to Eliminate Bubbles In Casting

This sequence chronicles Mr. Ross's process in successfully reproducing this model using an advanced mold making technique.

How To Pre-Mix Urethane Casting Resin - TASK™ 3

Properly pre-mixing a urethane casting resin is important to ensure the material cures properly.

How To Make a Two Piece Silicone Mold of a Knife

We demonstrate using Mold Star 30 silicone, a platinum silicone for mold making...

How To Make a 2 Part Mold of an Antique Rifle

How to make a two piece silicone block mold of an antique Kentucky long rifle

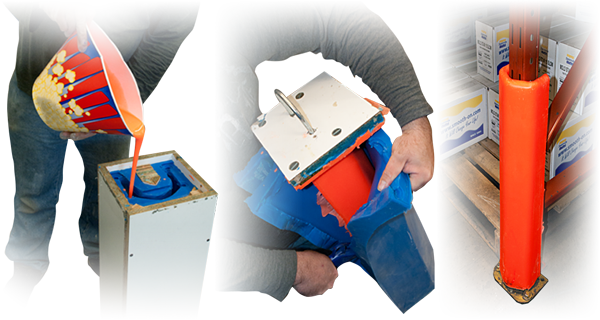

How to Use TASK™ 16 Rubber for Impact Resistant Bumpers

Owen Morris, contacted Smooth-On for a material to make custom bumpers that would help minimize the damage to their rack guards.

How To Make a Silicone Mold of a Prototype Using Smooth-Sil™ 960

The process of creating a very high accuracy silicone mold using platinum cure silicone.

Making a DIY HEPA Respirator Using TASK™ 8 Urethane Resin

Learn how to quickly make multiple respirators for personal protection

Using a Vacuum Former to Create Lightweight Wall Panel Artwork

How to to make beautiful decorative wall panels using a TASK 18 vacuum forming tool.

What Have Other People Done With These Products?

Moen Uses Smooth-On To Spark Development

Moen uses the full spectrum of Smooth-On tin and platinum-based silicone rubbers to develop and refine proposed design

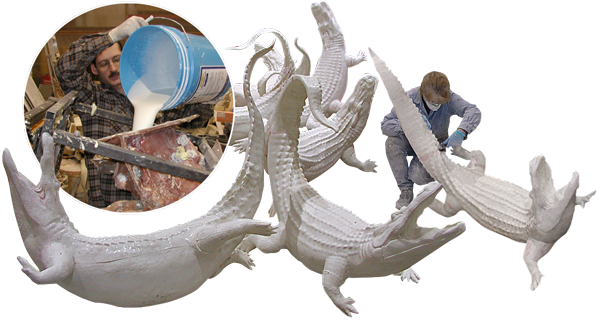

TASK® 15 Alligators Cast for a Good Cause

Beyond Design Studios delivered lightweight, rotationally cast alligator models

How To Make a Vacuum Forming Mold Using TASK™ 18 Urethane Resin

Parts that are thermoformed touch our lives every day including consumer packaging and advertising signs.

Theming Las Vegas: Smooth-On Products Used at Luxor Hotel & Casino

The Luxor is one of Las Vegas' best known hotels and casinos with its stunning Egyptian themed elements made with Smooth-On rubbers,

Making a Difference During the COVID-19 Pandemic With ATTA Inc.

ATTA Inc. in NYC donates over 1,200 visors made with Smooth-On materials