How To Use a Glue Shim on a Challenging Model

Overview

Customers often contact Smooth-On with specific mold making questions. One of the most common questions we're asked is how to create a mold from an original model that has a pass-through -- essentially a hole created by the configuration of the piece. Standing figures often have one or more of these pass-through's, usually between the legs or arms of the piece. If the mold rubber is simply poured over the original model, it will fill these voids and completely encapsulate the piece in a solid block of rubber. The original model would then have to be cut out of the mold rubber, which can be very difficult and is often imprecise.

In this photo sequence, we demonstrate another strategy for dealing with a common type of pass-through. This advanced mold making technique involves creating a “glue shim” that eliminates the need to cut the rubber away from the voids in the original model. Smooth-On’s SORTA-Clear® 40 silicone mold rubber is used to make the process even easier.

SORTA-Clear® 40 is a premium water white translucent silicone rubber (platinum catalyst) that cures at room temperature with negligible shrinkage. SORTA-Clear® 40 has a Shore hardness of 40A and features exceptional tear and tensile strength.

Materials Used in this Tutorial

- Super Seal

- Super Instant Epoxy

- SORTA-Clear 40

- Smooth-Cast 300

- SO-Strong Color Tints

- Mixing Containers

- Mixing Sticks

- Vacuum Chamber

- Water Clay

- Plastic Wrap

- Paint Brush

- Acid Brush

- Tongue Depressor

- Melamine Board

- Gram Scale

- Hot Glue Gun

- Hot Glue

- Mold Box

- Drill

- Razor Knife

Step 1: Prepare Model

In this tutorial the original model stands approximately 12'' (30 cm) tall and is made of unglazed ceramic. The two openings, or ''pass-through's'' on this piece create a mold making challenge.If these pass-through's are not addressed, the mold making rubber will encapsulate the piece and lock it within a solid block of rubber. Creating a glue shim eliminates the need to hand cut the silicone in these spots - a process that can be difficult and imprecise.

Prior to creating the glue shims, the piece should be sealed. Smooth-On's Super Seal® is perfect for sealing the unglazed ceramic original. Super Seal® is a very low viscosity sealer that can be brushed onto the original without distorting the details of the piece. A minimum of two coats of Super Seal® is recommended to ensure thorough coverage.

Step 2: Applying Clay For Glue Shim

The first step to creating the glue shim is to have a base onto which the epoxy can be applied. Begin by taking a portion of water clay and wrapping it tightly in plastic wrap. Position the plastic wrapped clay behind on the side of the pass-through. Push the clay into the gap. The clay will conform to the shape of the pass-through and fill the void. Then push the clay into any corners or small gaps around the perimeter of the pass-through.

Once the clay has been pushed into all areas, lay the piece down flat in preparation for applying the epoxy glue shim. Smooth-On's Super Instant Epoxy is a very fast setting epoxy, perfect for this type of application.

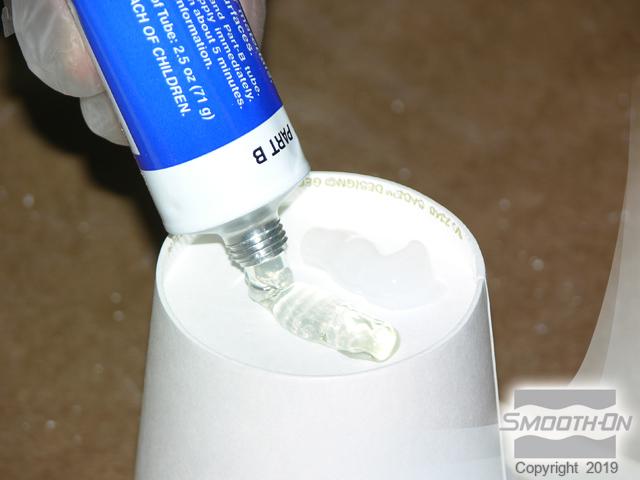

Step 3: Dispensing/ Apply Super Instant

Super Instant Epoxy is a two component epoxy that is mixed 1:1 by volume. Dispense a small amount of Part A. Then dispense an equal amount of Part B. Mix parts A and B thoroughly. Super Instant Epoxy has a very short working time of 2.5 minutes. It is important to keep this limited working time in mind when using the epoxy. Do not mix more than can be applied in this timeframe.

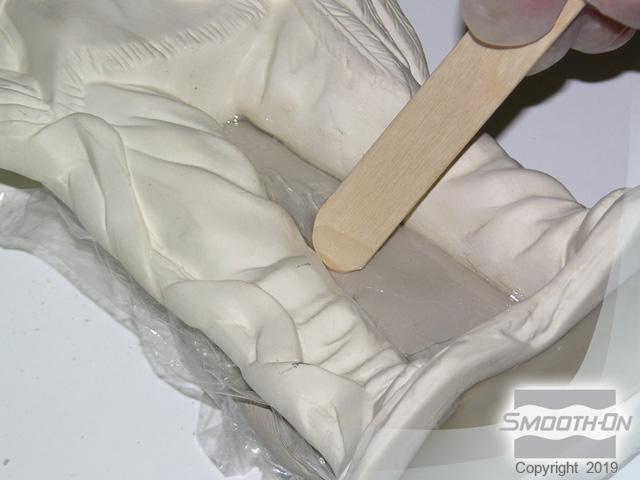

Using an acid brush, spread a thin layer of Super Instant over the plastic-wrapped clay. Using a tongue depressor, the Super Instant is spread carefully along the edges and into the corners of the void. The goal is to completely fill the gap, leaving an airtight film of Super Instant.

Step 4: Making Second Glue Shim

Another portion of clay is covered tightly in plastic wrap. This plastic-wrapped clay is pressed into the gap under the arm on the model. The application of Super Instant is repeated and the area under the arm is filled in.

Super Instant Epoxy is a very fast setting material. It has a 2.5 minute working time and cures to handling strength in 5-10 minutes. After this period, the plastic wrapped clay can be carefully peeled away from the cured Super Instant. The Super Instant will not stick to the plastic wrap and the thin film will remain in place. In the photos below you can see a close-up of the plastic-wrapped clay being removed from the glue shim under the model arm.

Once the Super Instant Epoxy has fully cured, the model is ready to for the mold making process.

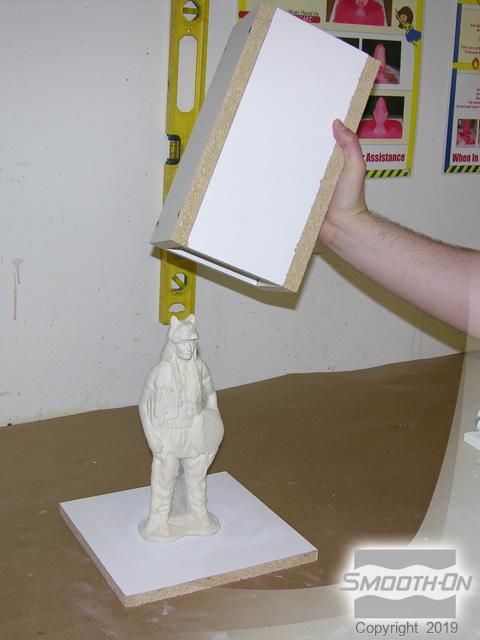

Step 5: Prepare Mold For Molding

Apply a bead of hot melt glue to the base of the model and then secure the model to a melamine board base. Cut more melamine board to size to make a mold box. Secure the mold box to the melamine base with more hot melt glue.

Step 6: Dispensing, Mixing, Vacuuming, and Apply Sorta-Clear

Important: Carefully read the technical bulletin and material safety data sheet prior to working with any material. These documents provide important information that will help make your mold making project a success.

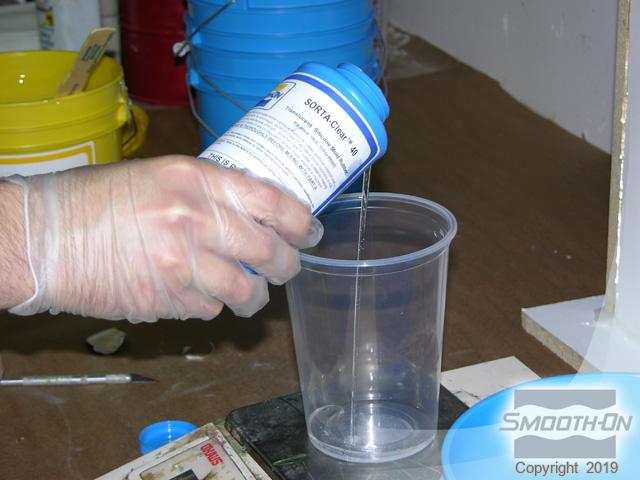

For this project, Smooth-On's SORTA-Clear® 40 is used. This material has a 100A:10B by weight mixing ratio. Using an accurate gram scale, measure out Part A. Prior to measuring Part B, it is important to shake or stir the material thoroughly. Then using an accurate gram scale, measure out Part B. And then combine Parts A and B. Trhoroughly mix the material following the instructions outlined on the technical bulletin.

For best results, and to eliminate the most air bubbles from the thick silicone rubber, SORTA-Clear® 40 is vacuum degassed. Vacuuming the material should be done at 29 h.g.

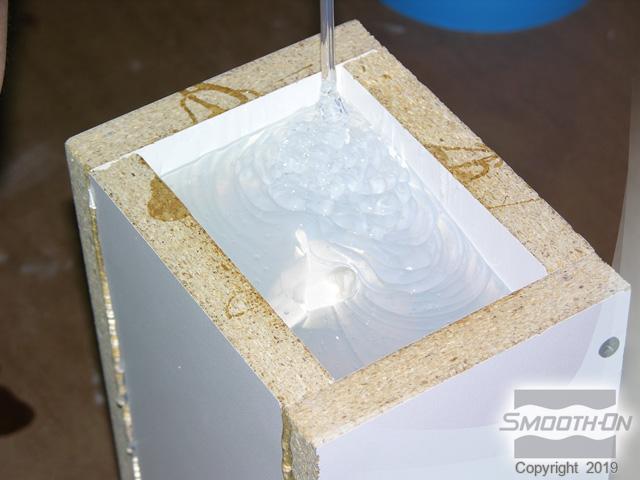

Slowly pour the SORTA-Clear® 40 silicone over the original figurine in the mold box. SORTA-Clear® 40 should be poured until the top of the model is covered with at least 1/2'' (1.25 cm) of mold rubber. Allow the SORTA-Clear® 40 to fully cure (16 hours) prior to demolding. Once the SORTA-Clear® 40 has cured, the mold box can be removed.

Step 7: Demolding

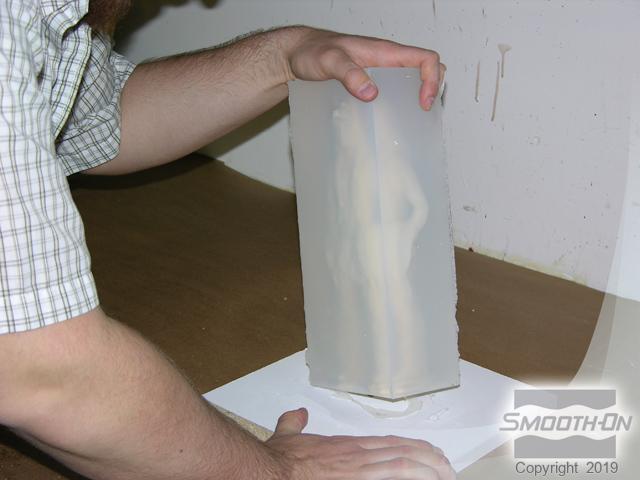

Pull the box walls away from the mold. Remove the mold from the baseboard. SORTA-Clear® 40 is clear enough that the original model can be easily seen within the solid block of rubber. This unique property of SORTA-Clear® becomes important when removing the original model from the mold. The translucent rubber is cut with a razor knife to allow for removal of the original piece. SORTA-Clear® makes precision cutting around an original much easier.

Once the mold has been cut down one side, the rubber is spread apart and the original model is removed. The completed mold, ready for casting.

Step 8: Finishing Casting

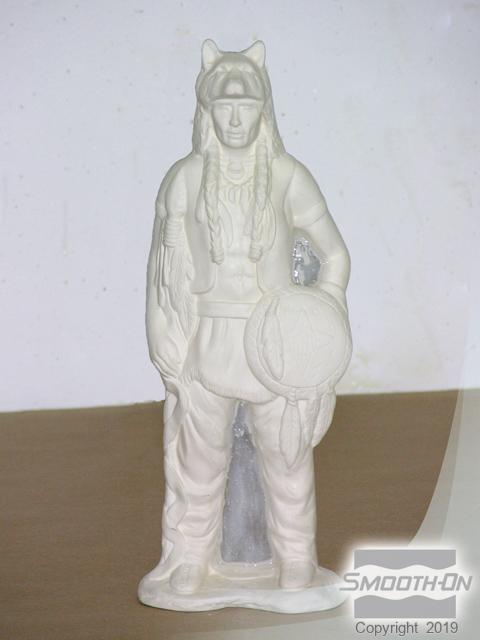

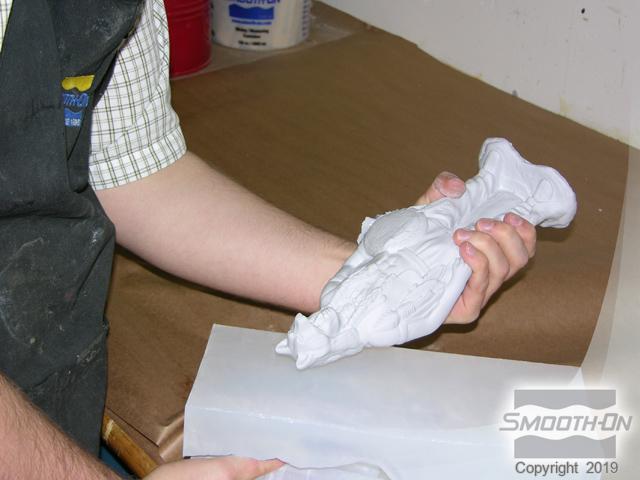

Band together the mold and pour in Smooth-Cast® 300 resin. Tint the resin slightly with SO-Strong® black. Once the Smooth-Cast® 300 has cured (approximately 10 minutes) remove it from the mold.

The casting reflects perfect detail captured from the original model. Using a glue shim will leave a very thin layer of plastic flashing within the pass-through's. The plastic flashing is very thin and brittle. It can be easily removed with a razor knife, and then sanded smooth for a seamless casting.