How To Use Equinox™ Putty to Replicate a Sea Fan

Step 4: Casting with Smooth‑Cast™ 60D and So‑Strong Colorants

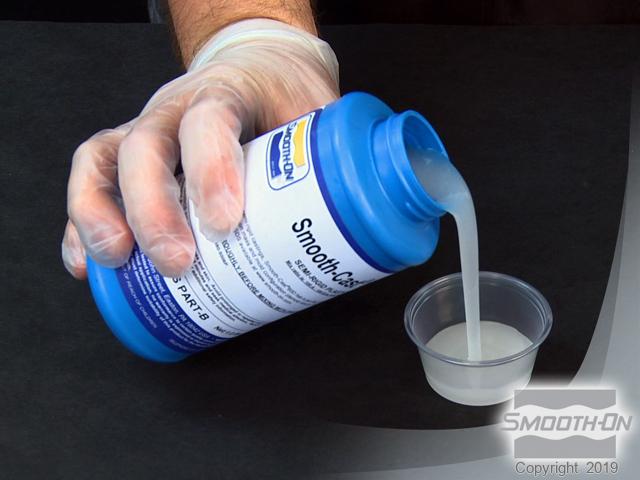

Smooth-Cast™ 60D semi-rigid urethane resin is used to make the casting. It has a mix ratio of 1 part A to 1 part B by volume. Dispense part A and then dispense an equal amount of part B.

To make the casting use 2 separate but equal batches that are pigmented different colors. They will then be combined when poured into the mold separately. SO-Strong urethane color tints are used to pigment the resin. These are ultra-concentrated, so a little goes a long way.

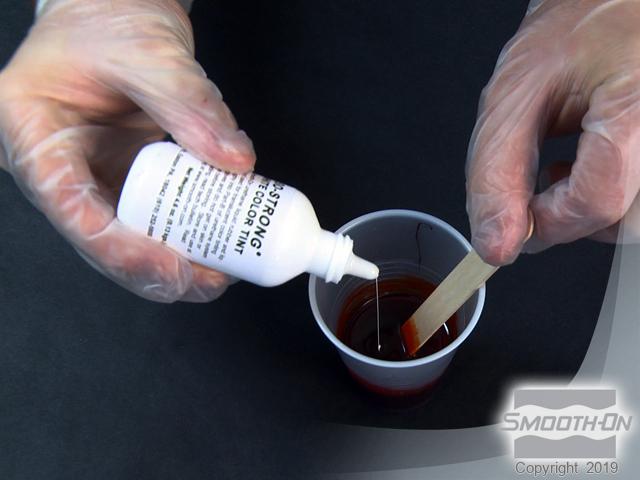

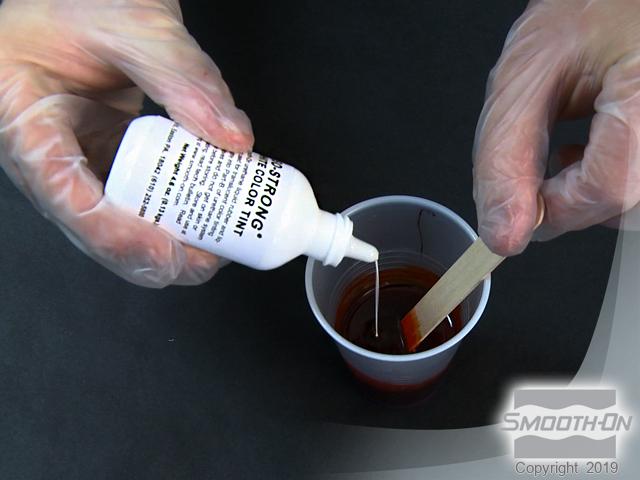

Transfer part B into a larger mixing container, for batch 1. Add SO-Strong red color tint. Mix red into part B resin thoroughly. Add SO-Strong white to the pre-mixed red. Stir red/white mixture until thoroughly blended. Set aside.

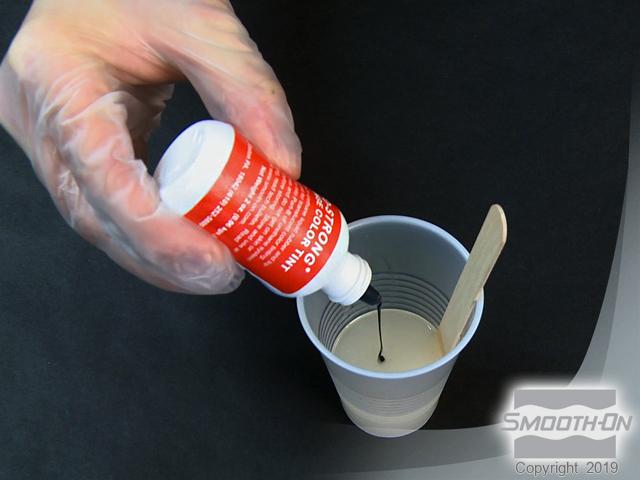

Transfer part B into a larger mixing container, for batch 2. Add SO-Strong orange color tint. Mix orange into part B resin thoroughly. Add SO-Strong white to the pre-mixed orange. Stir orange/white mixture until thoroughly blended. Set aside.

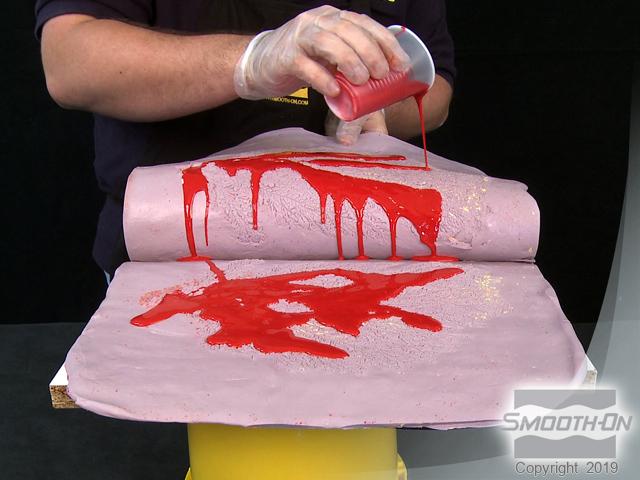

Pour part A into the pre-mixed part B (red/white) and mix thoroughly. This is a fast set resin, so you need to work quickly. Pour part A into the pre-mixed part B (red/white) and mix thoroughly. Elevate your base board and mold. Pour the red resin mixture into the mold on both sides. Pour part A into the pre-mixed part B (orange/white) and mix thoroughly.

Close the mold slowly, allowing the resin to flow into network of veins in the mold. Press and smooth the mold rubber to evenly distribute the resin. Replace the top board over the mold and press firmly. Use C-clamps to secure and tighten the mold. All 3 clamps have been tightened. Since this is a low-mass casting with thin veins, allow the resin to cure for at least 1 hour.