How To Make a 2‑Part Mold of an Architectural Bracket

Step 13: Applying Mold Max™XLS II

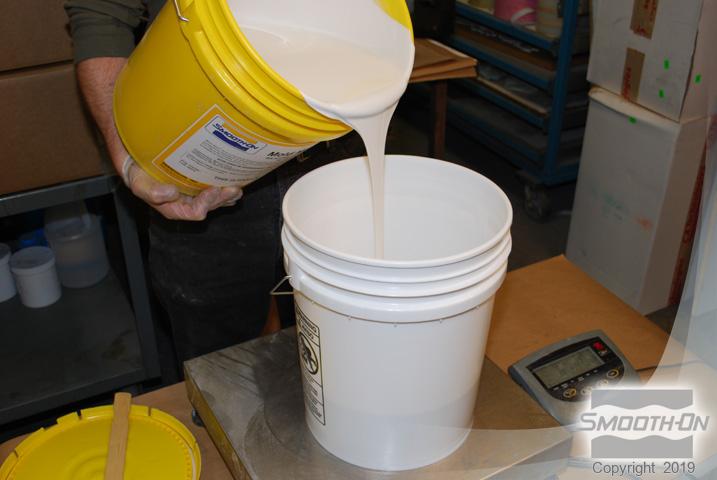

Mold Max™ XLS II measured 100A :10B by weight, after the material is dispensed it is then mixed and for at least 3 minutes and vacuum degassed. The rubber is poured over the model and the second-half mold box lid is placed over the rubber and secured with screws. Additional silicone rubber is then poured in the top of the mold box to fill the open void. Non-sulfur oil based clay is then used to plug pre-drilled vent holes. Additional wood is used to cap the mold box and Mold Max™ XLS II is set to cure for 24 hours at room temprature(73°F/23°C).