How To Make a 2‑Part Mold of an Architectural Bracket

Step 12: Inverting mold and Preparing for Part Two of the Mold Max™ XLS II

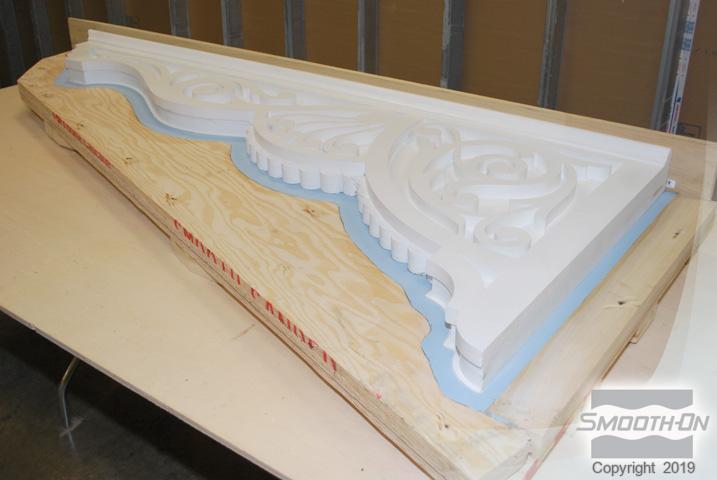

Mold box is turned over and the parting line wood and clay are removed from the model. Model in cured silicone ruber is thouroughly cleaned. Wood is cut to form mold box side walls and then secured with screws, additional wood is cut and attached on the sides to complete the mold box assembly. Ease Release™ 200 is sprayed to the cured silicone surface and then brushed into the detail. This prevents Adhesion between pours of rubber.