How To Make a 2 Piece Silicone Mold to Cast a Police Baton Prop

Step 2: Weighing, Dispensing, Pouring and Demolding Mold Max 30

Next, weigh out Mold Max® 30 Part A and Part B. The appropriate mix ratio is 100 Parts A to 10 Parts B by weight.

Dispense Part A into mixing bucket and then add Part B. Thoroughly mix material until there are no color striations in the rubber. Vacuum degassing minimizes bubble entrapment in thick silicone rubber.

Pour Mold Max® 30 in a long, thin stream over the original. Continue pouring until the highest point of original is covered with at least 1/2'' of silicone. Once the rubber has fully cured, remove the clay and place the block back in the box. Do not remove the original!

Spray Ease Release® 200 over the entire surface. This will allow the silicone to separate from itself.

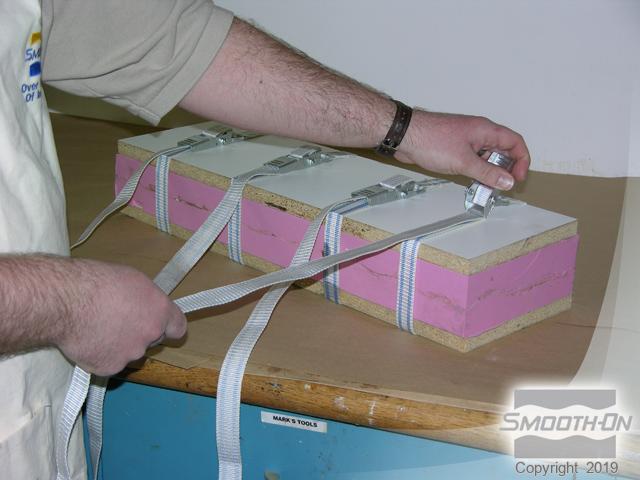

Mix and pour a new batch of rubber. The highest point of original should be covered with at least 1/2'' of silicone. Once the rubber has fully cured, remove the original model from the mold. Use adjustable straps to clamp the mold together. Wooden boards prevent the straps from deforming the rubber.