How To Make a Prop Rattlesnake Using Dragon Skin™ Silicone

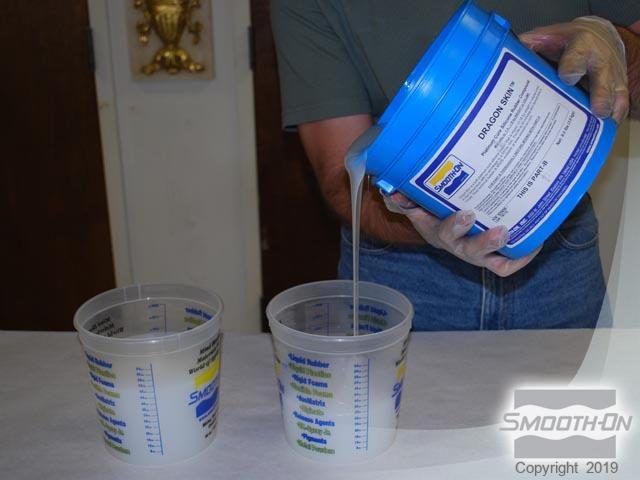

Step 2: Dispensing, Mixing, Vacuuming and Pouring Dragon Skin 10 Medium

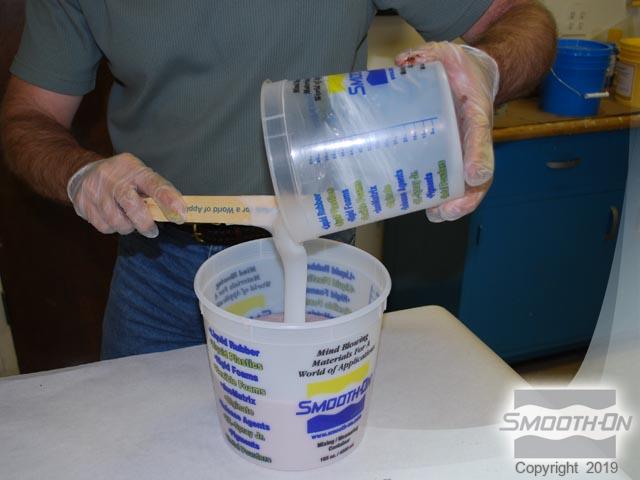

Dispense Part A of Dragon Skin® into a convenient graduated clear container. Then dispense an equal volume of Part B.

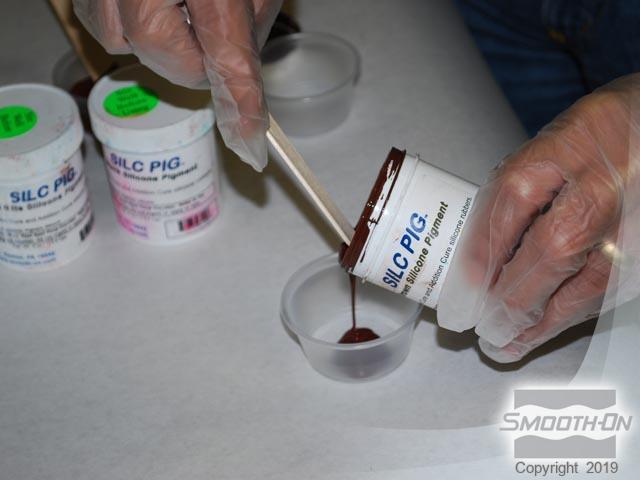

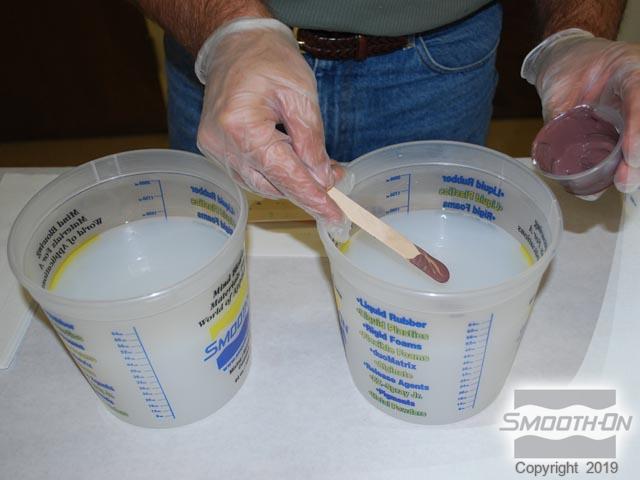

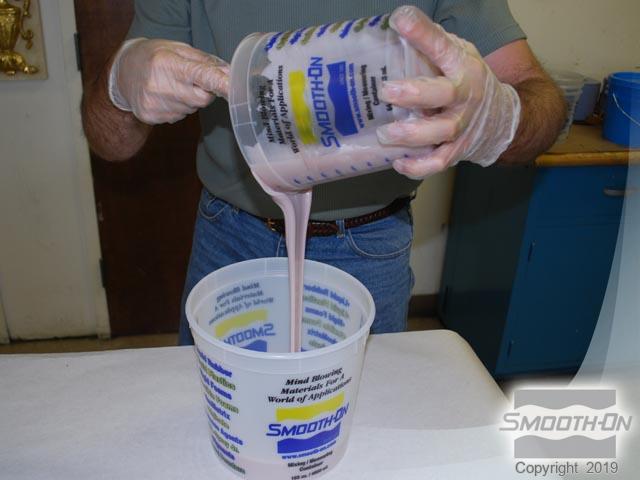

Next, combine SilcPig® color pigments to yield the desired brown tone of the rattlesnake, Pigment is pre-mixed. Then add a small amount of pigment to part B. This will base tint the rubber casting a light beige color.

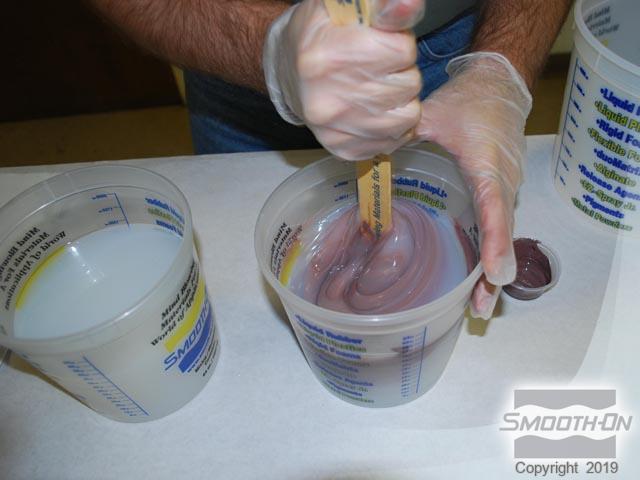

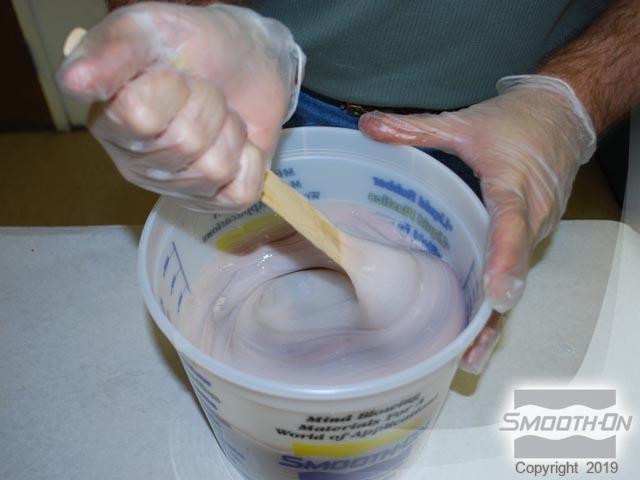

Now, Dispense Dragon Skin® Part A into a larger container for mixing and then add pigmented Part B. Mix the Dragon Skin®.

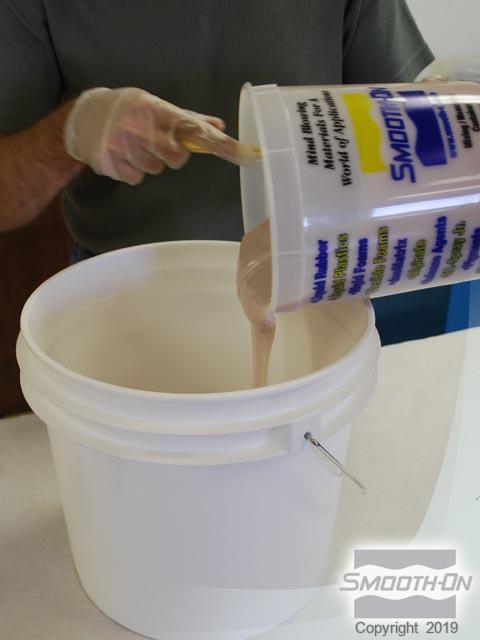

Dispense the material into a 5 gallon bucket for double mixing and vacuum degassing. Take care to scrape the sides and bottom thoroughly stir the material again. Then place the Dragon Skin® in a vacuum degass chamber. The Dragon Skin® silicone is de-aired at the proper measurement of 29 inches of mercury. After the rise and fall cycle, the rubber is ready for casting.

Pour the material into the mold in a thin ribbon minimizes air entrapment while dispensing into the mold. Allow the material to cure.