How to Make a Silicone Brush On Mold of a 3D Object

Step 3: Dispensing and Applying Plasti‑Paste to Create Support Shell / Demold

Measure and mix Plasti-Paste®, 1A to 3B. Scrape sides and bottom of container to ensure a thorough mix. Apply the Plasti-Paste® over the surface of model, platform and shim, to 3/8 inch (.95 cm) thick; then allow the Pasti-Paste® to cure for at least 90 minutes at room temperature (72º F / 22º C). Once cured, fold the aluminum foil out of the way towards the cured Plasti-Paste®. Remove the clay shim.

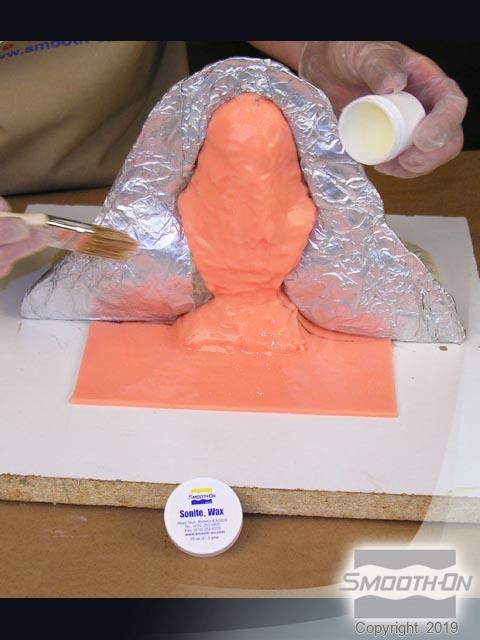

Apply a liberal coat of Sonite Wax® to the surface of the aluminum foil and baseboard. Let the Sonite Wax® dry for 10 minutes and apply a second coat. Measure Plasti-Paste®, 1A to 3B and mix thoroughly. Apply Plasti-Paste®, over the surface of model, platform and shim to approximatly 3/8 inch (.95 cm) thick and allow the shell to cure for at least 90 minutes at room temperature (72ºF/22ºC).

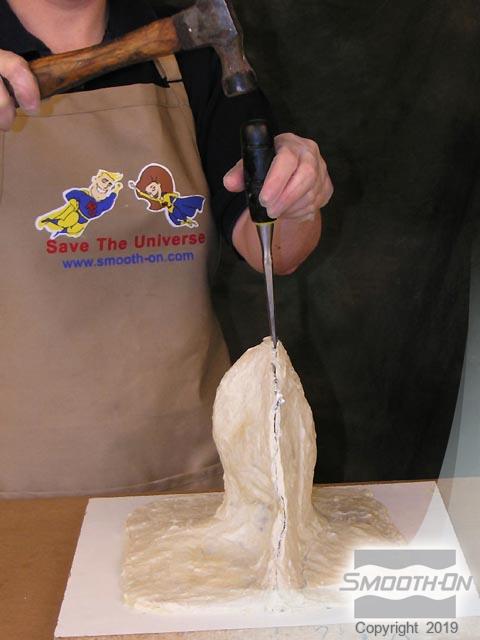

When cured, remove excess aluminum foil. Use a hammer and chisel or screwdriver to seperate the shell sections. Slowly pry the support shell segments apart and release from baseboard. Remove the sections to expose the rubber mold.

Use a razor knife to carefully cut the rubber seam from bottom to top. And gently remove the original model from the rubber mold. WARNING: RAZOR KNIFE IS SHARP!