How To Vent a Silicone Mold to Eliminate Bubbles In Casting

Step 7: Preparing and Casting Task 4

Assemble the mold haves, making sure that the mold keys are aligned and locked.

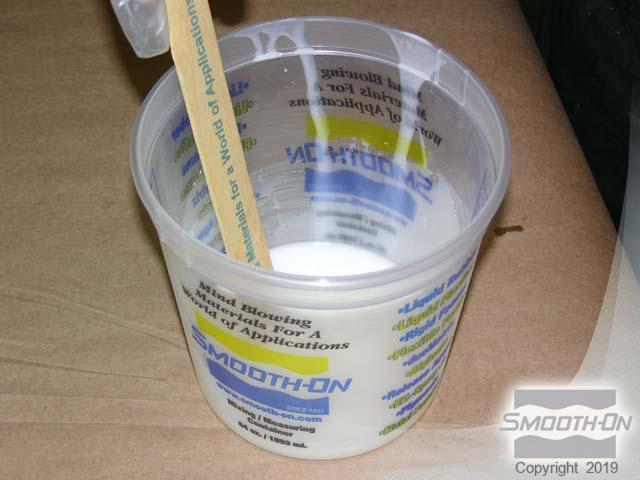

Dispense TASK® 4 Parts A and B by weight and mix the components together thoroughly. Using a syringe, inject the liquid plastic into the vent hole created in the previous step. Allow the mixture to seek its level within the mold. You will know the mold is filled when the liquid plastic becomes visible at the top of each vent hole. Allow the TASK®4 to cure overnight.

The next day, separate the mold halves to reveal the finished casting; a perfect reproduction of the original model! Remove the flashing around the casting perimeter with an exacto knife.