How To Make Flexible Foam Prop Cinder Blocks

Step 3: Demolding FlexFoam‑iT Casting

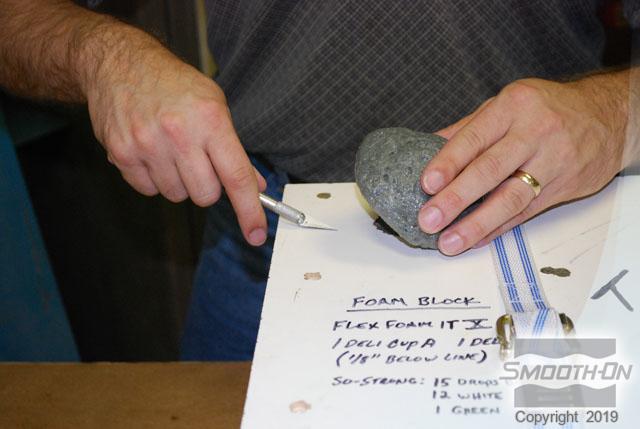

Allow the foam to rise and cure for 1 hour and then cut away any extra foam material. Remove the mold straps and take the lid off of the mold box. Once small pour vent spruces are cust away from the casting, the piece is ready to demold! Begin by inverting the mold and removing it from the wood mold box. To push out the wood supports, use a wooden rod. Now the mold is ready to be fully opened. Peel away the sides of the mold and pull the flexible casting away from the rubber mold. This reveals a perfect casting, requiring only a small amount cleanup!