How To Make a Silicone Glove Mold and Faux Wood Casting

Step 4: Dispensing, Mixing and Applying Third and Final Layer of Dragon Skin 10 Very Fast

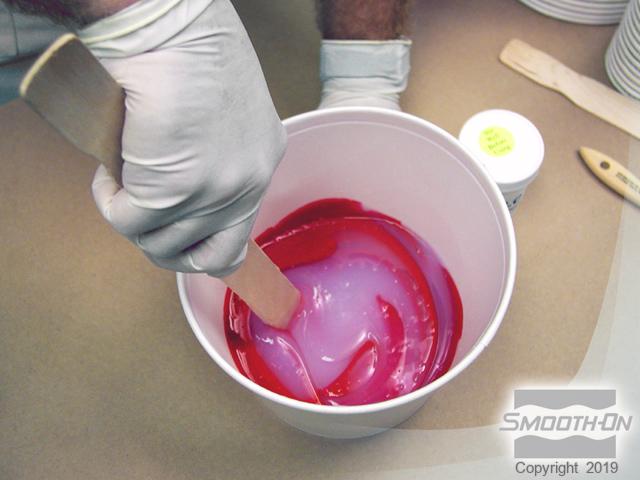

Mix a third batch of Dragon Skin™ 10 Very Fast silicone, adding additional THI-VEX™ II thickening agent to this layer. Using much thicker material means the mold can be built up faster. Use a stick to trowel the thickened rubber over the previous layer. Cover entire model and continue building flange. Allow rubber to cure until tacky (approximately 20 minutes).

Mix a final batch of Dragon Skin™ 10 Very Fast with some THI-VEX™ II added. Brush this batch over all other layers. This layer will further build thickness, but will also smooth out the surface of the mold, making application of a support shell easier. Ultimate mold thickness should be approximately 3/8'' (1 cm). Allow rubber mold to completely cure (approximately 60 minutes).

‹ Previous: Dispensing, Mixing and Applying Second Layer of Dragon Skin 10 Very Fast

Next: Preparing Mold For Support Shell ›