How To Make a Silicone Glove Mold and Faux Wood Casting

Step 9: Preparing and Casting Smooth‑Cast 300

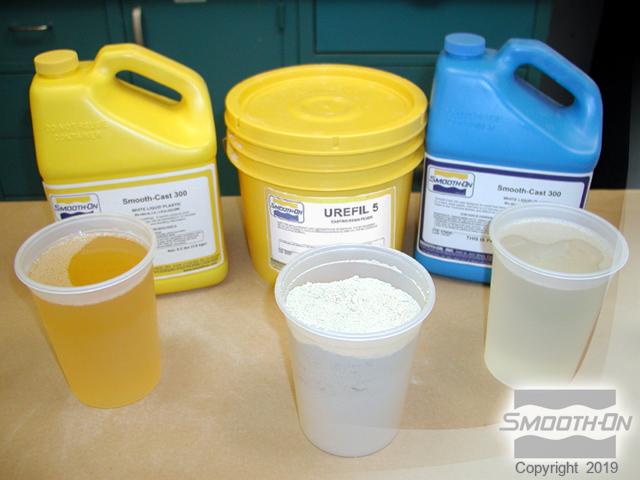

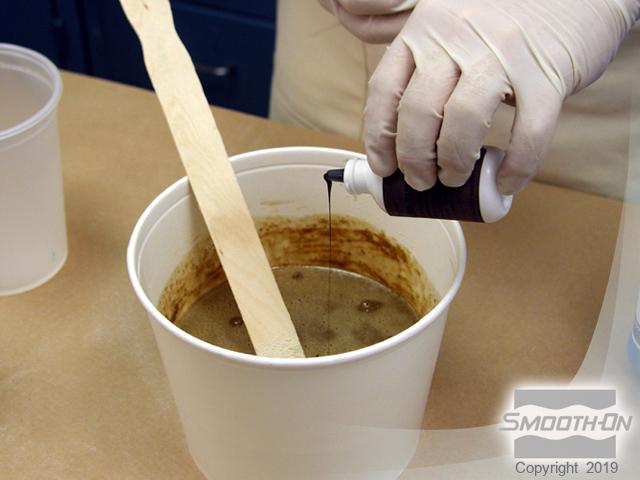

Re-seat the Dragon Skin™ mold into the Plasti-Paste™ support shell. Rubber bands are used to bind the two halves of the shell together. Invert the mold and place it into a bucket. Once the mold is level, the casting process can begin. When reproducing woodgrain, it is important to use the appropriate combination of resin and filler. Smooth-On's Ure-fil™ 5 is combined with Smooth-Cast™ 300 to create a woodgrain finish. The proper mix ratio is 1 Part A to 1 Part B to 1 Part filler by volume. Combine all elements. Adding SO-Strong™ Brown pigment will result in a casting closer in color to the original. Mix all elements thoroughly until no color striations are present. Once thoroughly mixed, pour the resin/filler mixture slowly into the mold.