How To Handle Large Undercuts In The Brush‑On Mold Making Process

Step 4: Create a Thickened Layer

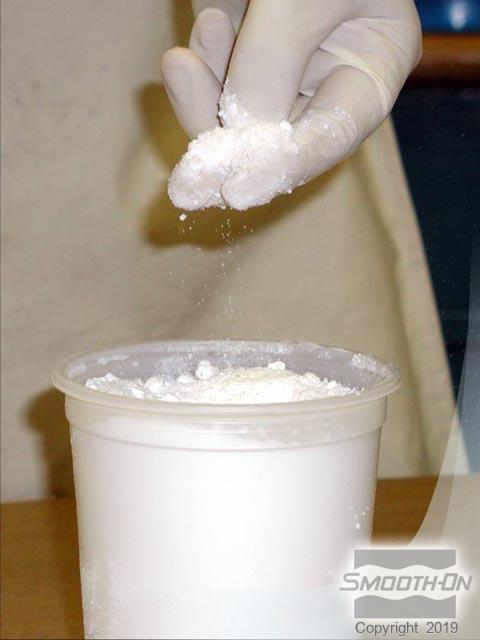

Apply a thicker layer with more fluid strokes. Allow the rubber to again become 'tacky'. Thicken Rubber With 'Ure-Fil 9', stirring in gradually until the desired thickness is achieved. 'Mashed potato' like consistency is perferred by many mold makers. Thickened rubber is good for filling undercuts, and good for making parting shims that will aid in registering cut rubber sections during casting. Fill in the undercuts, packing the material tightly to eliminate large air voids. Make the parting shim starting from top and building the shim evenly. Trying to build the shim to full thickness in one step often results in 'slumping' or an 'avalanche', so make sure to sculpt the seam evenly from top to bottom. Fill in all undercuts.